ROTO 101

Cylinders RZ/HV

Third in a 4 Part Series on Key Elements of the Rotogravure Process

In previous articles, I discussed “Bottom Line” profits and losses and how everyone needs to be held accountable to ensure profits are held to their maximum. I also discussed personnel, training, and the importance of establishing procedures.

We all know that money is lost in the printing process, in part due to issues I discussed earlier. Unfortunately, a majority of our profits are lost during the period from when the job actually starts to when the job is completed. The quality of tools we use (cylinders, ink/ink filtration, and doctor blades) are directly related to whether or not we have a positive/negative profit margin, and if we, as printers, decide to purchase these tools based on cost alone, we can only expect to get what we pay for.

Poor Quality In/Poor Quality Out

All three “Key Elements” (cylinders, Ink filtration and doctor blades) are equally important; however, I need to discuss them in this specific order because cylinders and ink filtration directly impact the success or failure of doctor blades. These three elements will be covered only as they relate to printers who are using solventbased ink—the reason being that 95 percent of gravure printers in North America are solvent-based.

CYLINDERS

Maintaining consistent quality of gravure cylinders affects your “Bottom Line,” and RZ (chrome roughness) and HV (chrome hardness), the process elements of your cylinders, are most likely inconsistent from one cylinder to the next. And, what does this cause? Process variation!

Cylinder quality is inconsistent for two primary reasons:

- 1 – The cylinder manufacturer does not have its process under control.

- 2 – You are not specific enough in requesting element parameters.

Printers continue to allow cylinders to be delivered to their pressrooms with huge variations in both RZ and HV, but this is not only the engraver’s responsibility. It’s also the responsibility of the printer! These variations will create the need for the operator to investigate and determine what the causes of printing issues are during the run. They will cause printing defects, downtime, questionable product quality, and waste. If the operator cannot “cure” the issue completely while running the material, then from the point the issue started to the end of the roll may be complete waste.

RZ – CHROME ROUGHNESS

The RZ (chrome roughness) is necessary to:

- 1 – Lubricate – Lubricates the doctor blade to reduce the contact area temperature to ensure the doctor blade wears into smaller fragments instead of melting, which forms burrs, which we all know causes drag outs.

- 2 – Sharpen – Keeps the contact area of the doctor blade clean (reduce defects) and sharp (cleaner print).

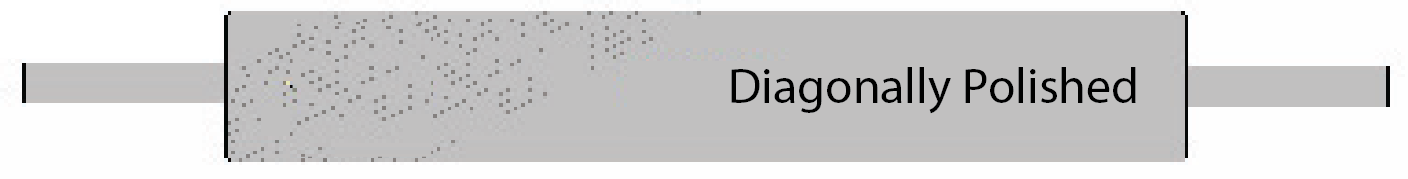

One of the biggest misconceptions in rotogravure is what the actual RZ roughness of the cylinder is and what it should be. Some customers will tell you that they have a spec of .20μm or .30μm. If they are testing with a Profilometer, this may be the case; however, the Profilometer does not distinguish between a polish that is cylindrical (figure 1) and one that is diagonally polished (figure 2). The illustration below shows that both types of polish direction could have the same RZ value.

Figure 1. Cylindrical Polish

Figure 2. Diagonal Polish

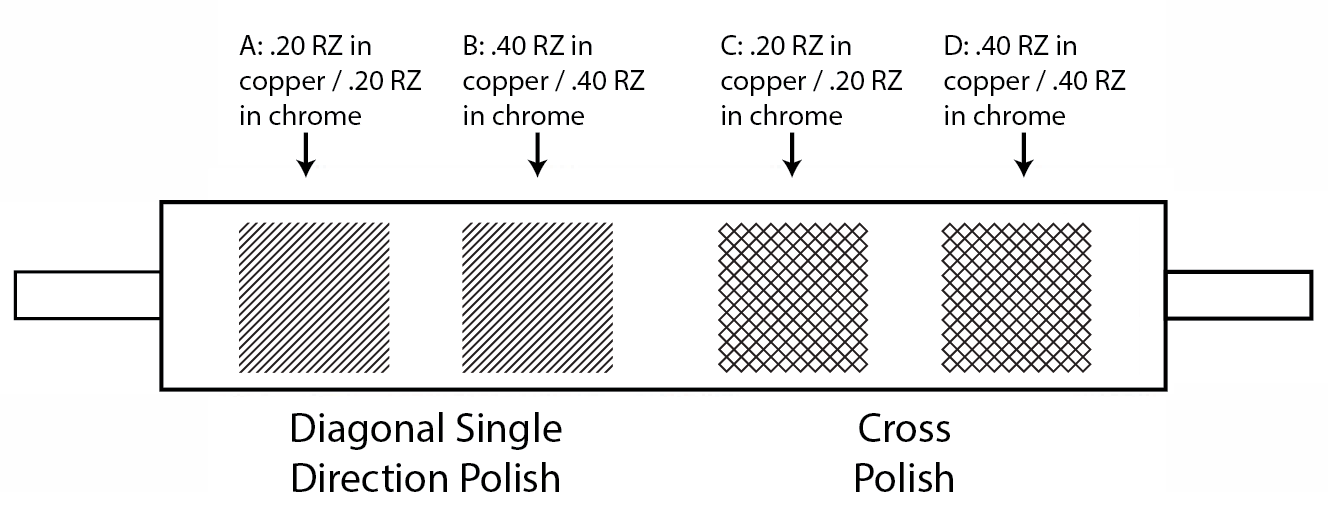

It is extremely important to specify not only the RZ value to your cylinder supplier, but also the direction as well. There is no question in my mind that the most effective polish direction is 45°. I have also found that a diagonal polish in a single direction is much more effective than a “cross polish” or “S” polish, which is commonly put in by our cylinder vendors.

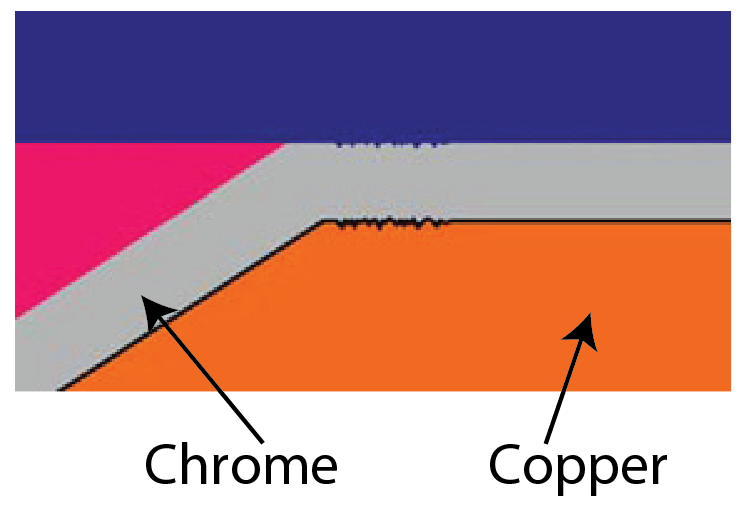

Polishing in the copper seems to be much more effective than just polishing in the chrome. There is some dispute as to why this is effective. The question stems from the fact that when the polishing is done in the copper and then plated with chrome, the thickness of the chrome is 20 times the thickness of the original RZ put into the copper (figure 3). Once the finished chrome is polished, the copper RZ, which was mirrored by the chrome, is removed.

Figure 3.

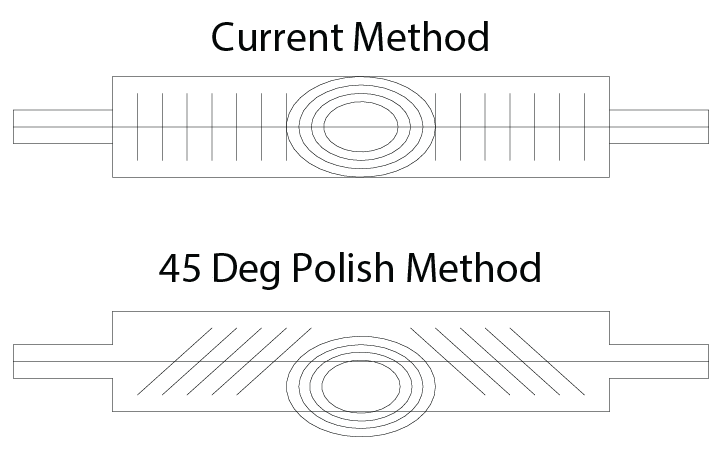

However, since the normal polishing technique is to stone polish in the copper (current method figure 4), there are already cylindrical polishing scratches in the copper. This along with the “Cross” or “S” polishing done in the chrome may be detrimental to the effectiveness of the overall polish. If possible, lowering the stone 25 percent (45° polish method figure 4) will create a much better polishing profile, which will add to the overall polishing effectiveness.

Figure 4.

The finish chrome RZ value that I found works the best for most applications is .40 μm for printing film and .60 μm for paper. The difference is the surface tension of the two substrates. The RZ can be verified with a profilometer as pictured below.

Figure 5.

HV – CHROME HARDNESS

The HV or chrome hardness is extremely important for several reasons:

- 1 – The chrome hardness must be much greater than the hardness of the doctor blade you are using to prevent premature cylinder wear.

- Wear will create reduced color strength during the run.

- Wear will lead to a dechrome and rechrome, or even a remake, costing printers thousands of dollars and tremendous downtime. How many makereadies are planned in your jobs? Probably only one. So, who pays for the second one? You do!

- 2 – The hardness of the chrome, being greater than the doctor blade, must maintain the RZ initially put in prior to the run to keep the doctor blade performing correctly.

Figure 6. Hardness File Set

CHROME THICKNESS

The thickness is also important in regard to cylinder life. Make sure that you are getting what you pay for. It’s a good idea to spot check cylinders periodically using an “Isoscope” (figure 7). In order to control your process, you must make sure your cylinder specifications are correct before and after the run. It is well worth the cost to create a position of “Cylinder inspector” whose duties should include: testing incoming cylinders (HV, RZ); testing cylinders after the run; cylinder spot repair; and shipping/receiving cylinders. This will help eliminate cylinders as one of the suspects if problems arise during the run.

Figure 7. Isoscope

Do your operators polish the cylinders during the run? Why do you feel they do this? It’s because they are restoring the polish that has been worn off! Unfortunately, this is another weak area for both engravers and printers. Rarely does the engraver know the chrome hardness he is delivering to his customer, and, in most cases, the printer has no idea.

The reason, according to the engravers, is that they feel there is no way to properly check chrome hardness other than sending in a chip for analysis. This takes time and money and may only take place once per month. The problems are: What if the chrome bath is contaminated on the day after the analysis? And, what about the quality of the cylinders for the next 30 days?

I have found a simple tool to use for the “Go/No Go” decision-making process. This tool is by no means “Dead on” accurate; however, it will give you enough information to determine whether or not your cylinders are hard enough to hold up against the doctor blade you are using. A standard carbon steel doctor blade is 550HV. If your doctor blade is harder than the cylinder, your cylinder may degrade. This tool will test hardness up to 865HV. If your cylinders test harder than 865HV and the blade you are using is 550HV, you should be safe from chrome degradation and severe scoring.

Figure 8. Example of a banded cylinder

Get involved with your engraver and work together to set up specifications that work best for your application. Have a banded cylinder done with several different polishes to determine what works best for you. Once your specifications are set, hold everyone accountable for maintaining these specifications.

Note: I have visited several engravers and have found their process to be very impressive. These engravers do want what’s best for their customers. Sometimes, surprisingly, it’s the printer who doesn’t ask for or expect the best.

To recap what we have discussed so far:

- 1 – Change is necessary and good.

- 2 – Bottom line profits must be maximized to remain competitive.

- 3 – The importance of establishing policies/procedures and training all employees accordingly.

- 4 – Everyone must be held accountable (managers, employees and vendors).

- 5 – Cylinder quality is a key element that must be controlled to reduce process variation.

All of the Key Elements must be held to a tight standard to eliminate process variation. Do not accept a range for tolerances. Pick a value and expect that value. This will reduce process variation.

If you need help with assessments or training for the best doctor blade solution, contact one of our experts for a consultative evaluation. Our team will be able to help you with solutions.

Download Technical Article

About the Author

Steve Boettcher is a 23-year veteran of rotogravure and no stranger to all facets of the pressroom. For two years Steve fixed presses as a mechanic. He operated a rotogravure press for ten years, and spent eight years at different levels of pressroom management at several major flexible packaging companies including Menasha Corp, Milprint, Alcan, and American Packaging.

For the last three years, Steve has been the Technical Service Manager for FLXON, Inc., a printing-solutions company. His main role has been to educate printers on pressroom efficiencies and the direct relationship doctor-blade quality has on achieving these efficiencies. Steve also performs doctor-blade analysis and is the product manger/designer for the new G-2 product line.

Steve’s goal is to educate every printing manager on the responsibility they have to ensure that the “Key Elements” (Doctor Blades, Ink, Cylinders and Operator practices) of printing are understood and that every vendor is held accountable for delivering consistent, quality products.

Recent Comments