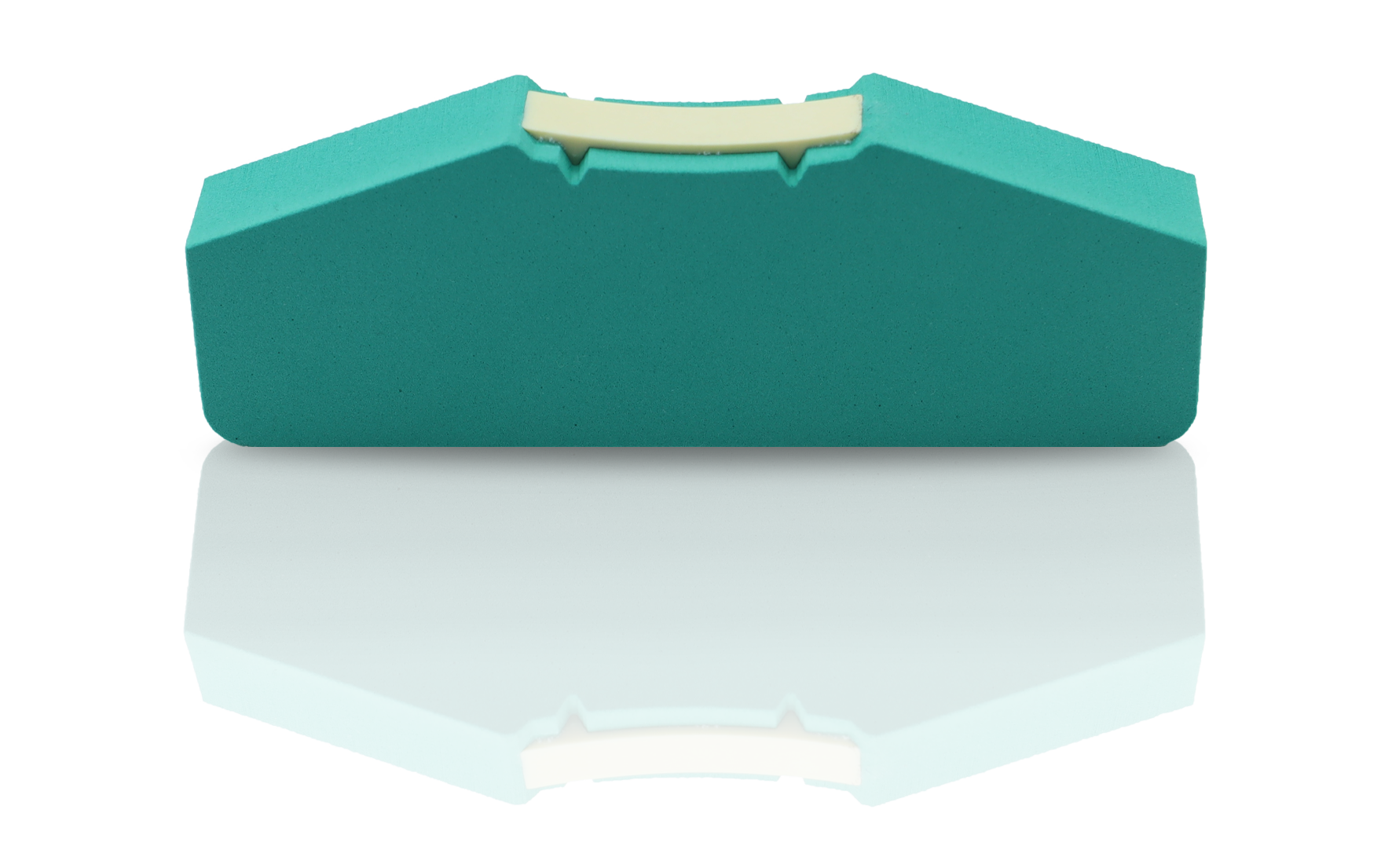

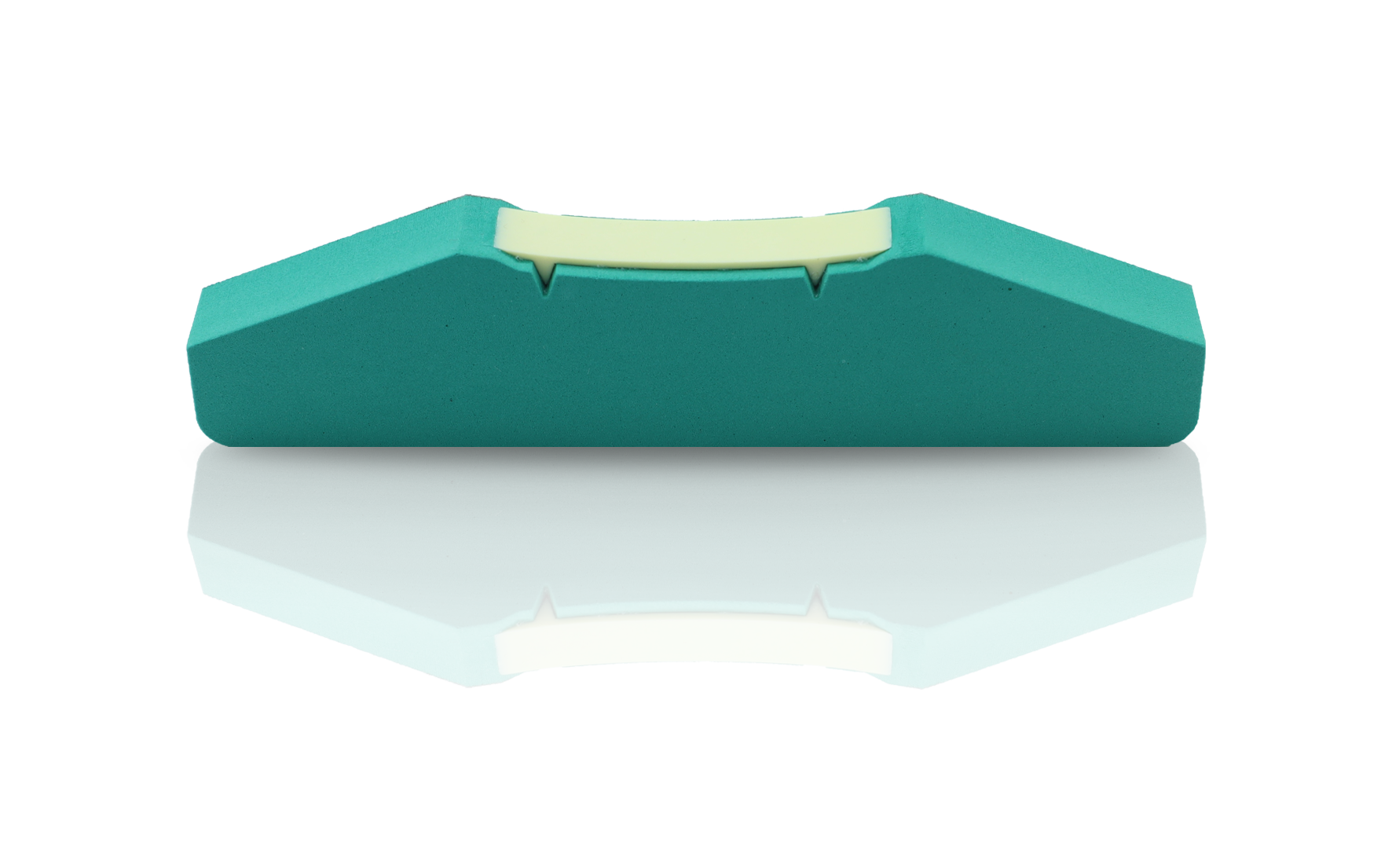

G2 ProSeals®

The Perfect Seal for Reduced Downtime & Cost Savings

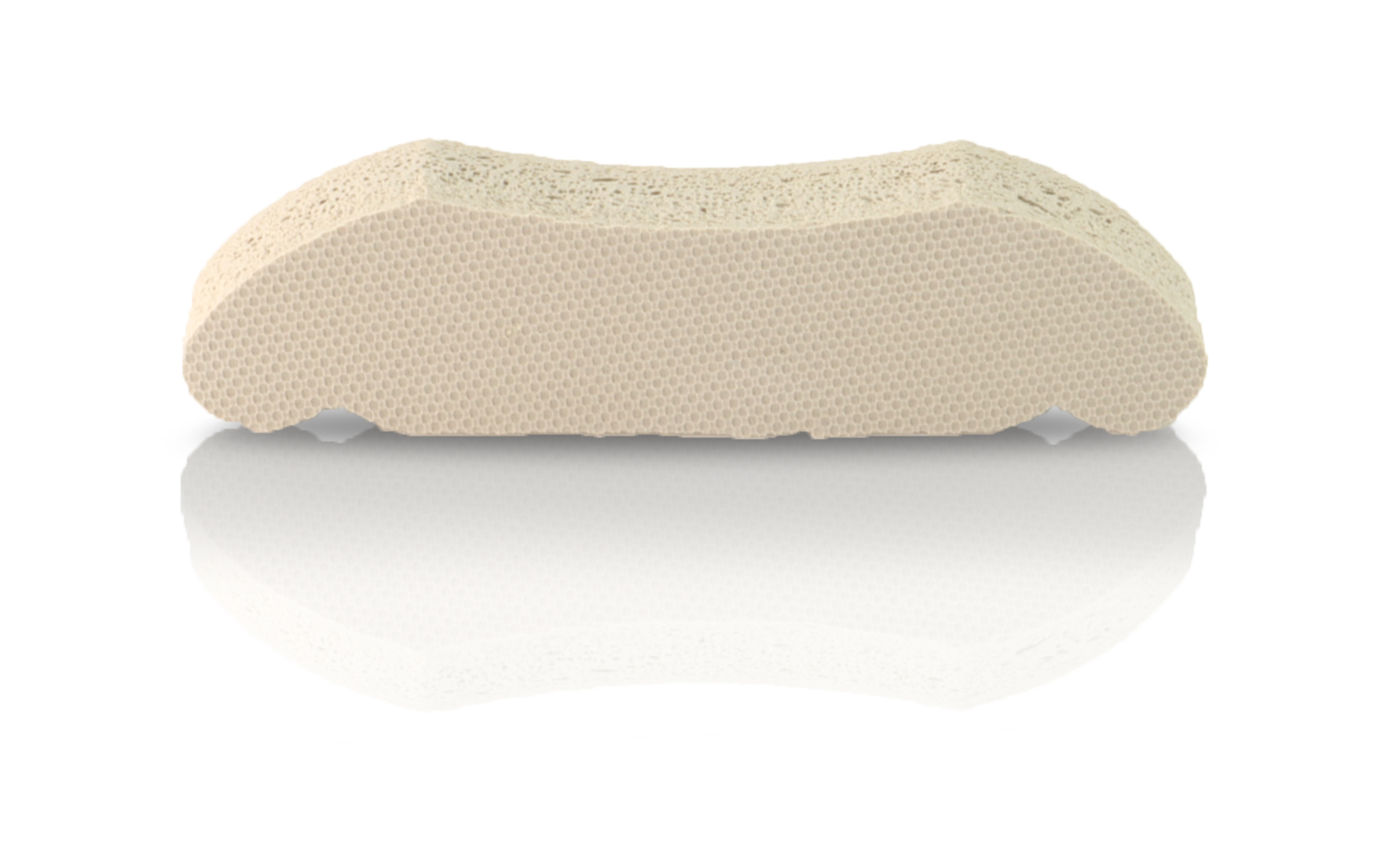

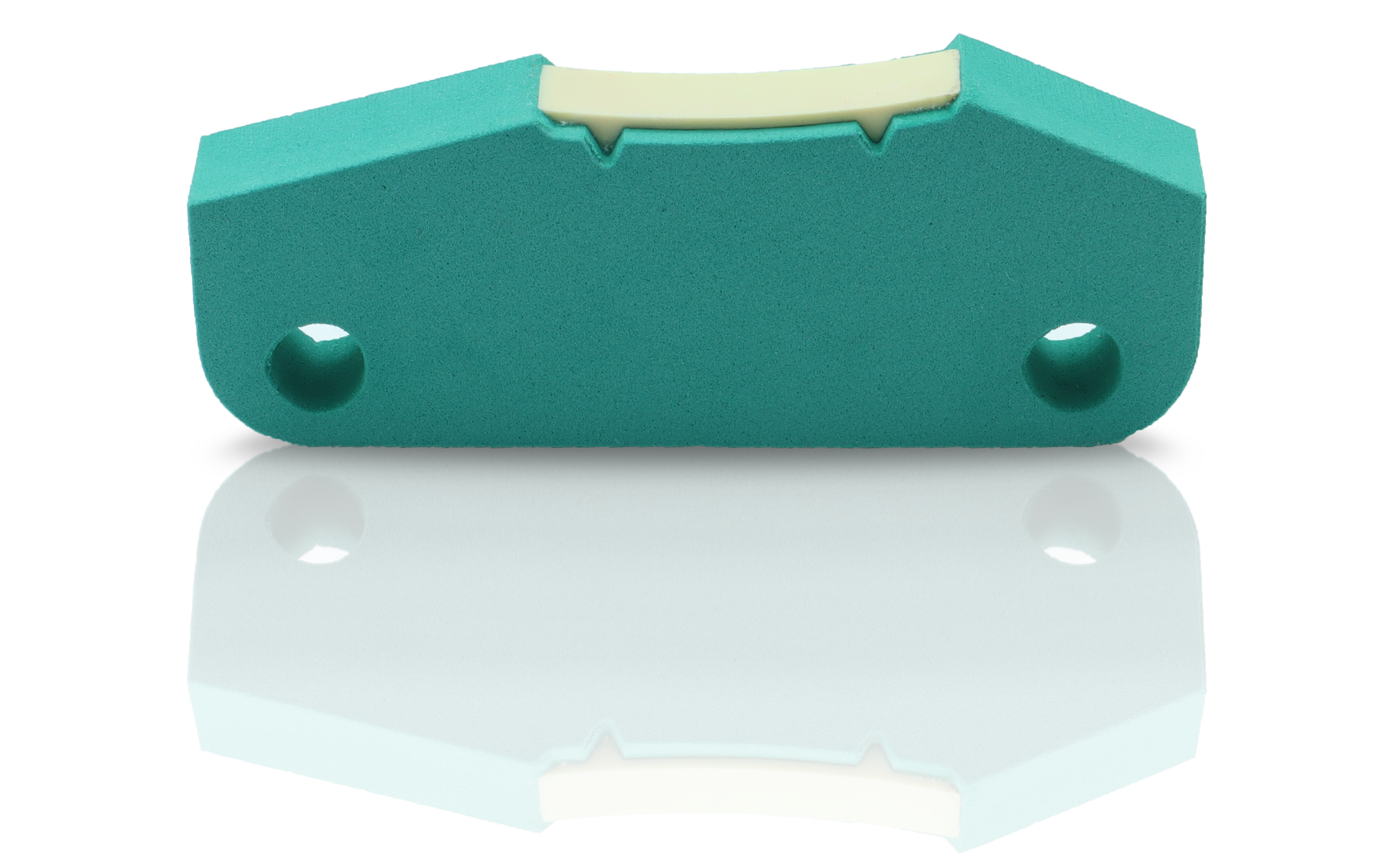

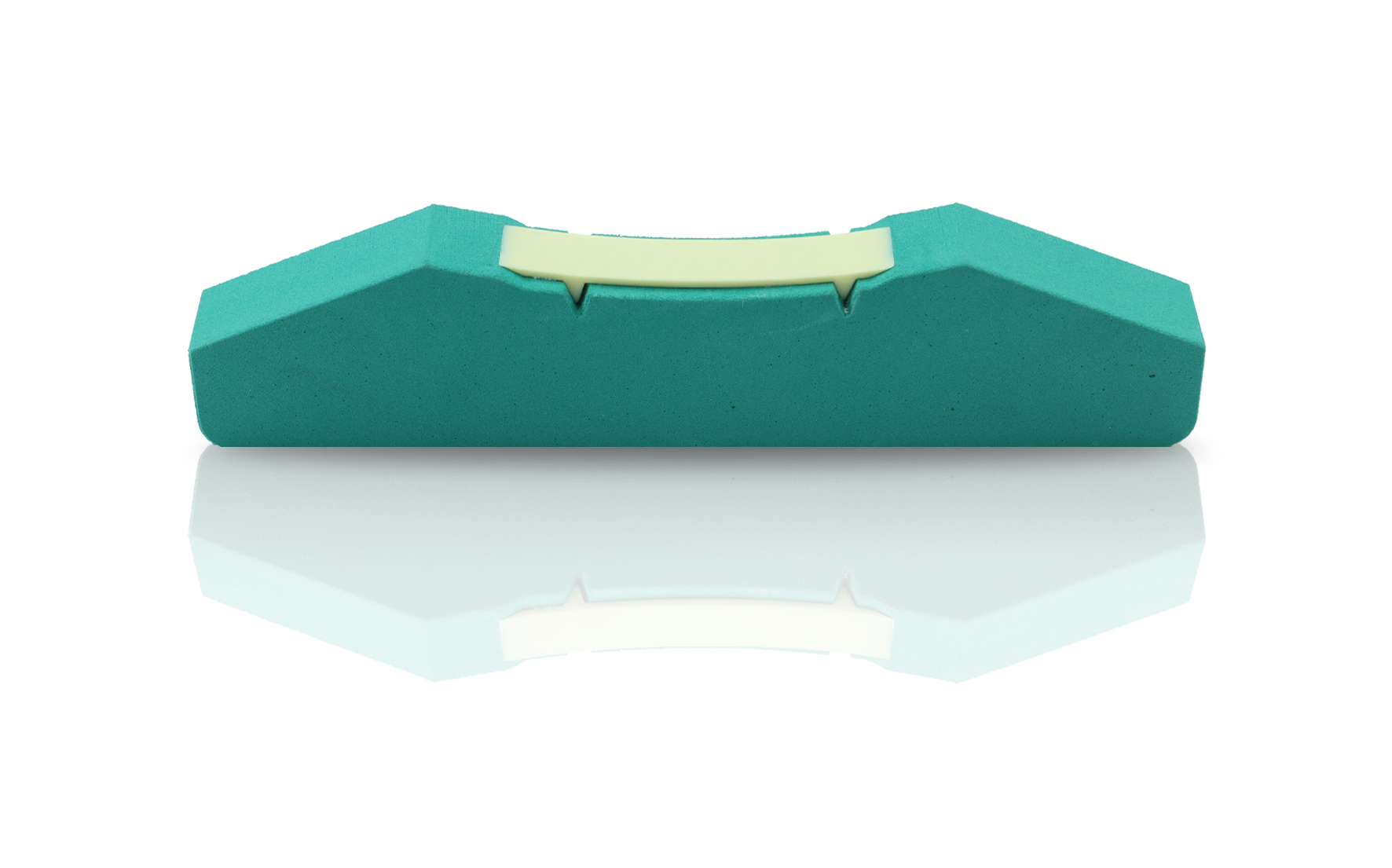

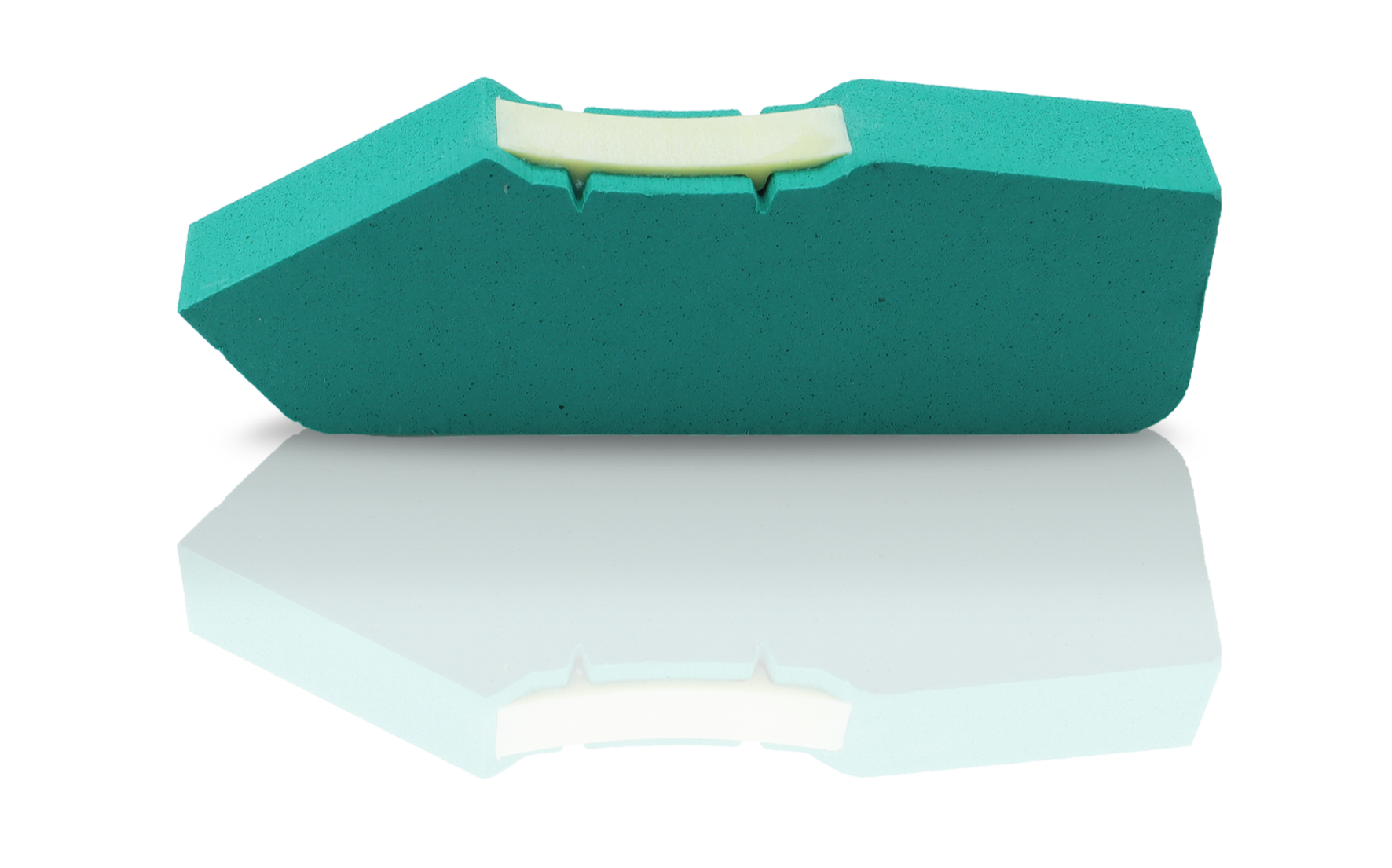

As flexographic printers continue to push the boundaries with ever increasing productivity goals, they are looking to eliminate sources of downtime and waste. The ProSeals have been developed to provide the maximum seal life in the industry and to match the blade life achieved with the newest generation of SWED/CUT® doctor blades.

Market testing to date has proven our ProSeals to achieve over a week of productivity on many common flexographic presses on the market.

HIGHLIGHTS

- Printers are achieving over 1 week and over 10 million ft of production with limited to no leaking

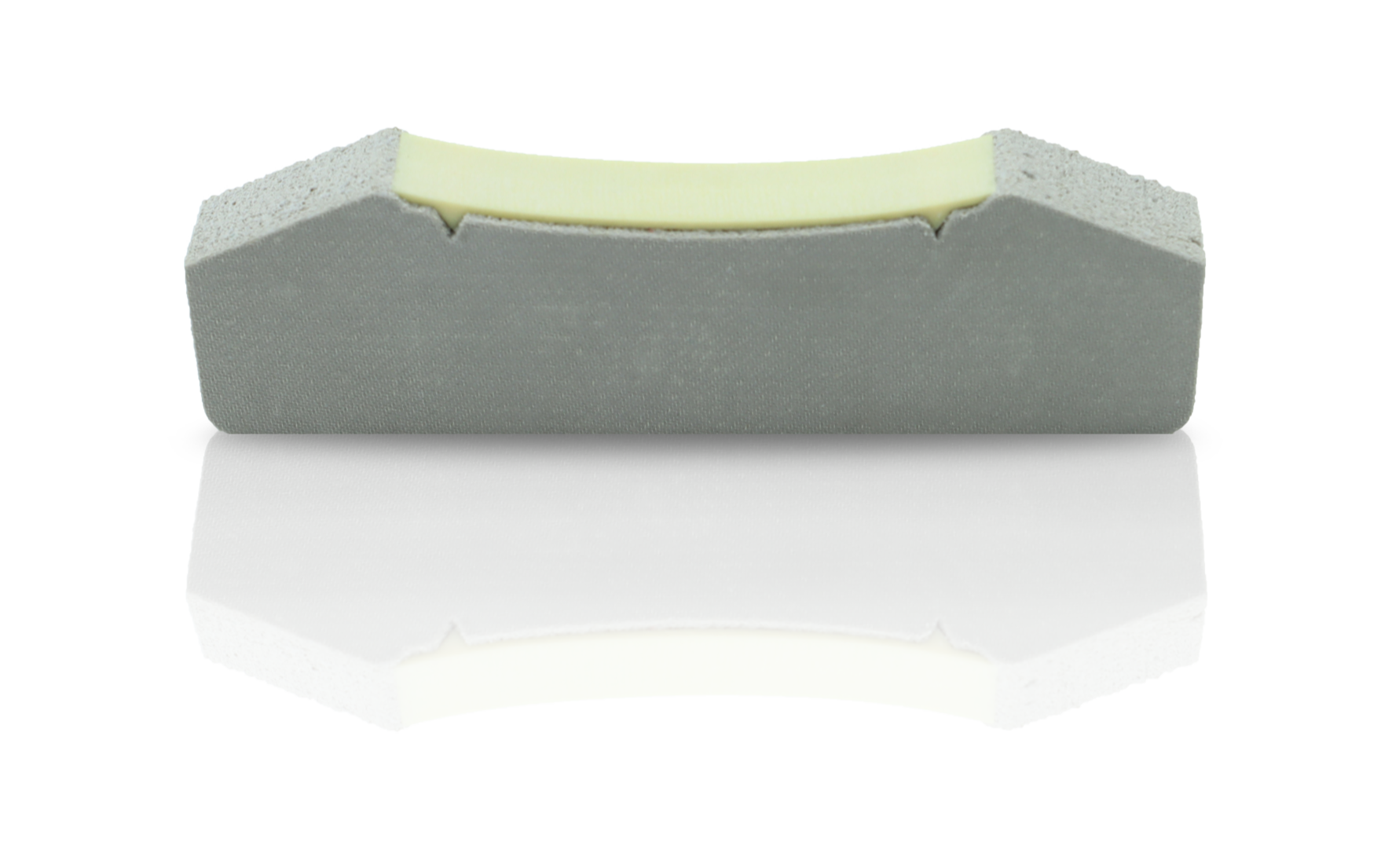

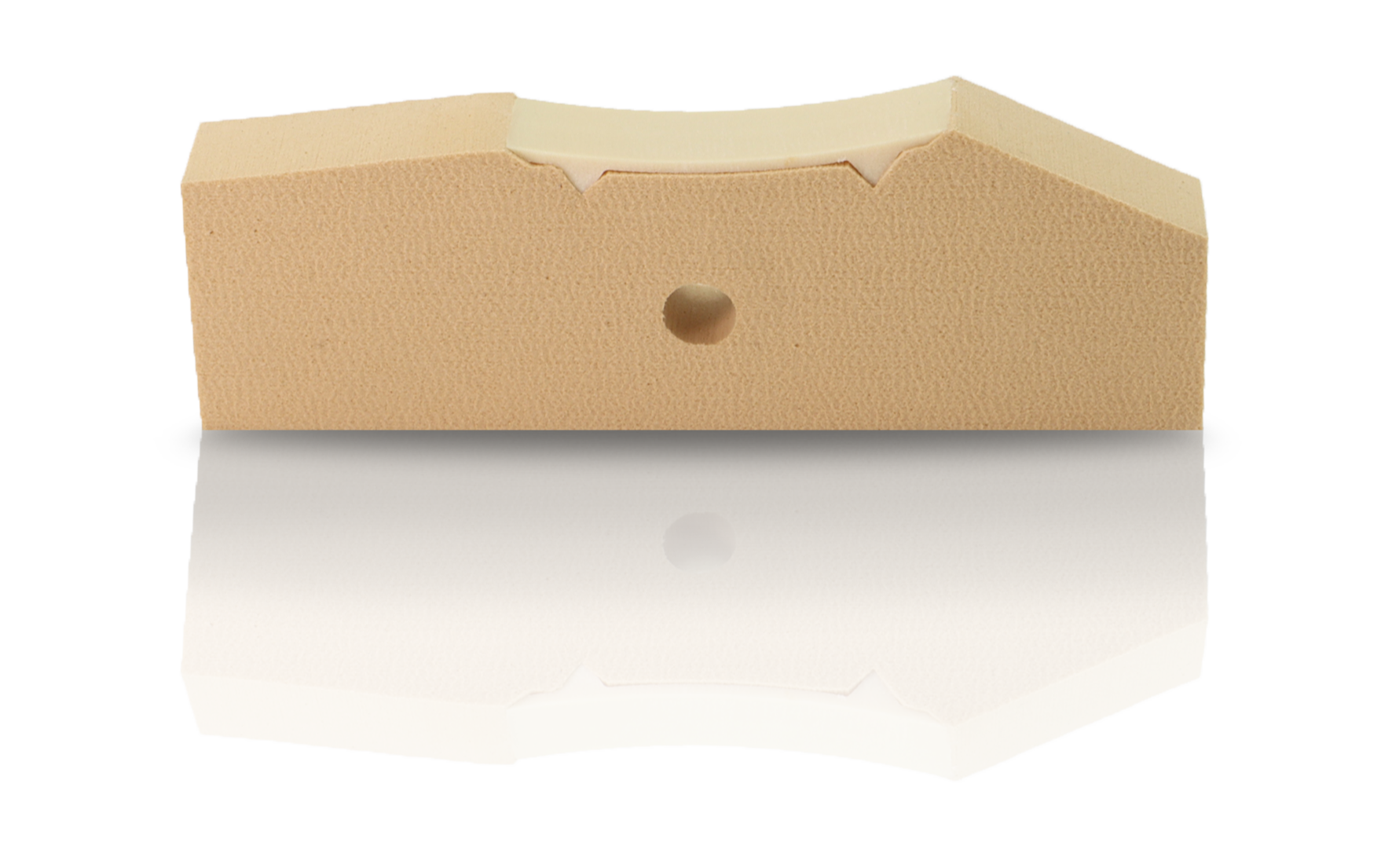

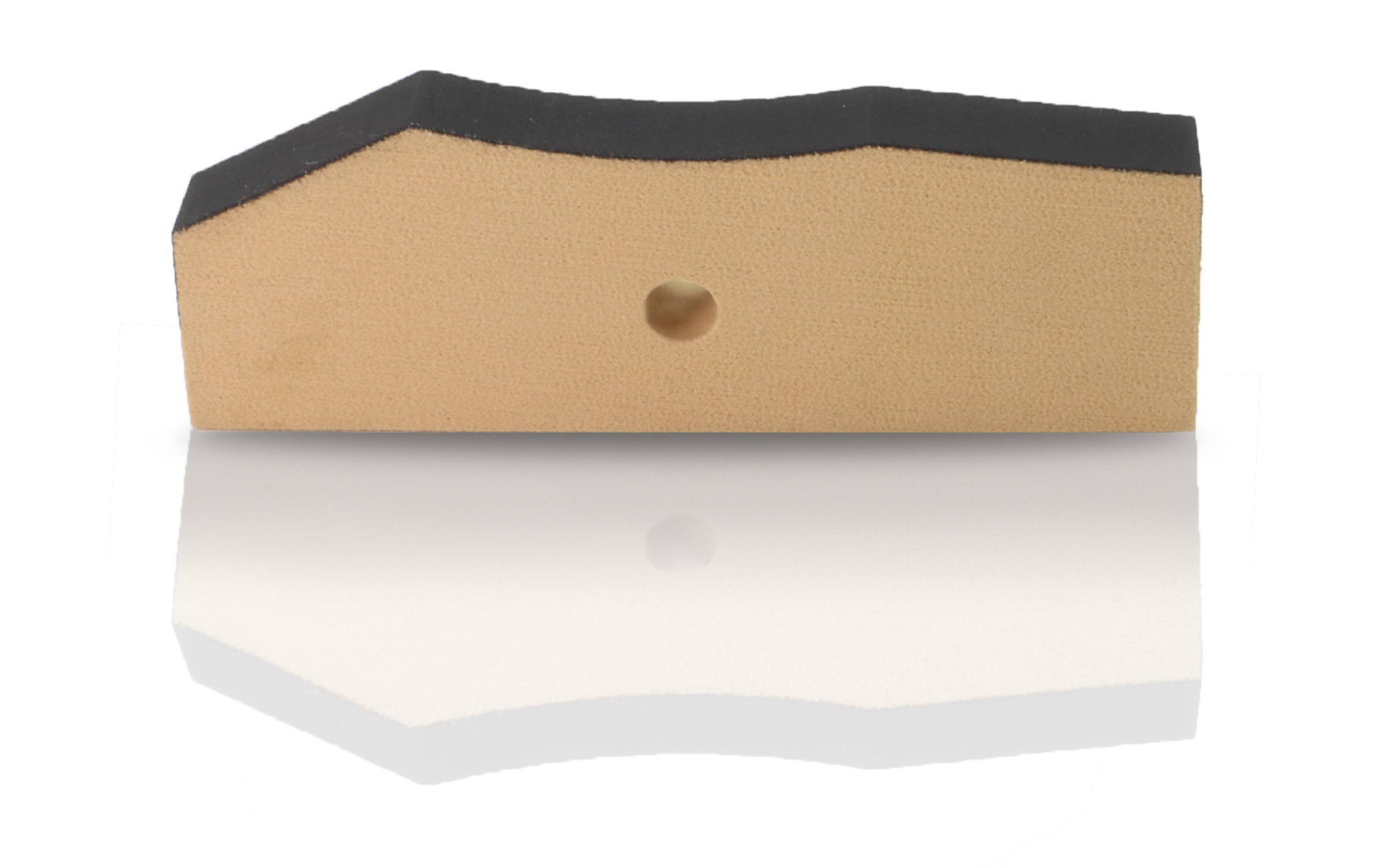

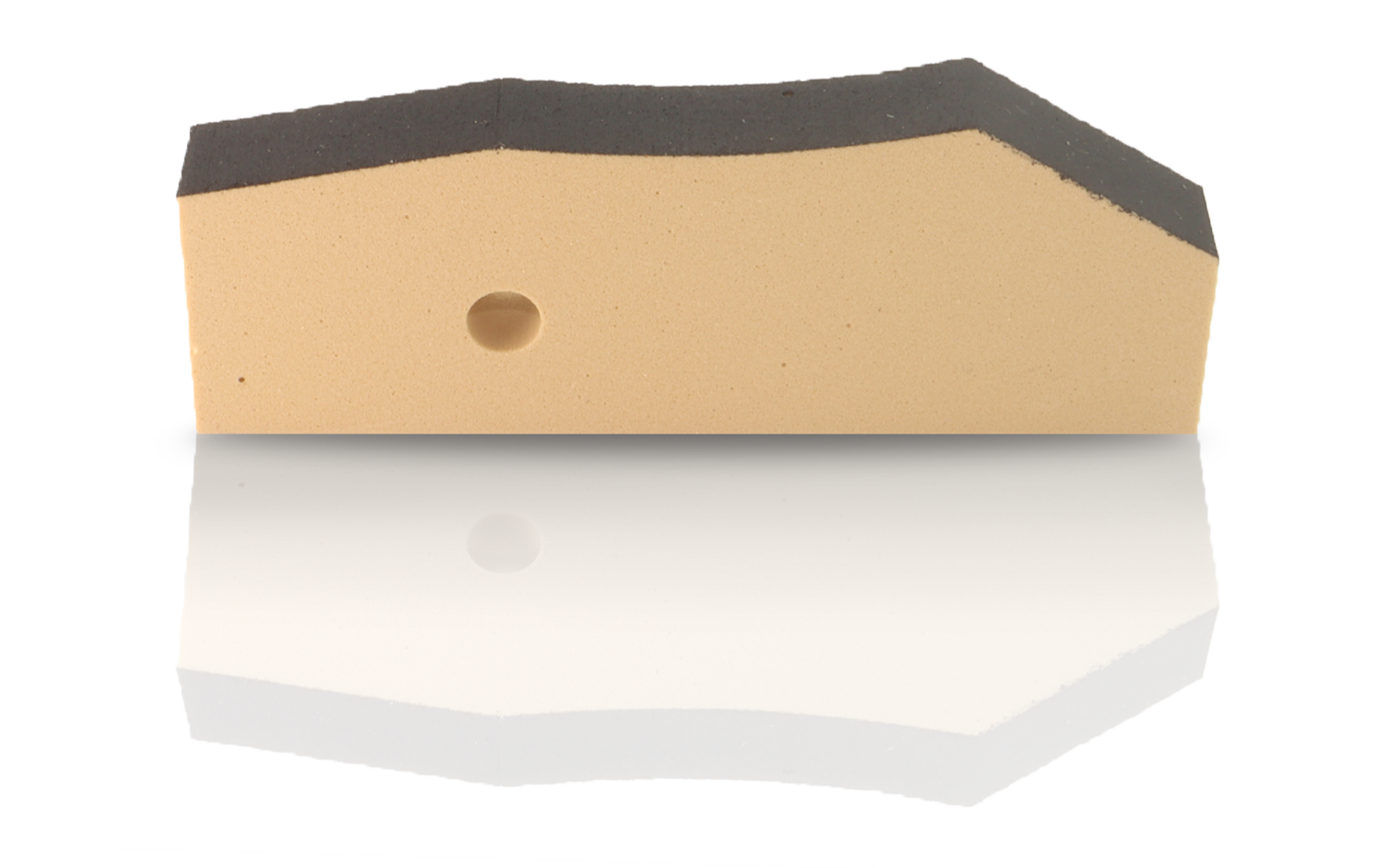

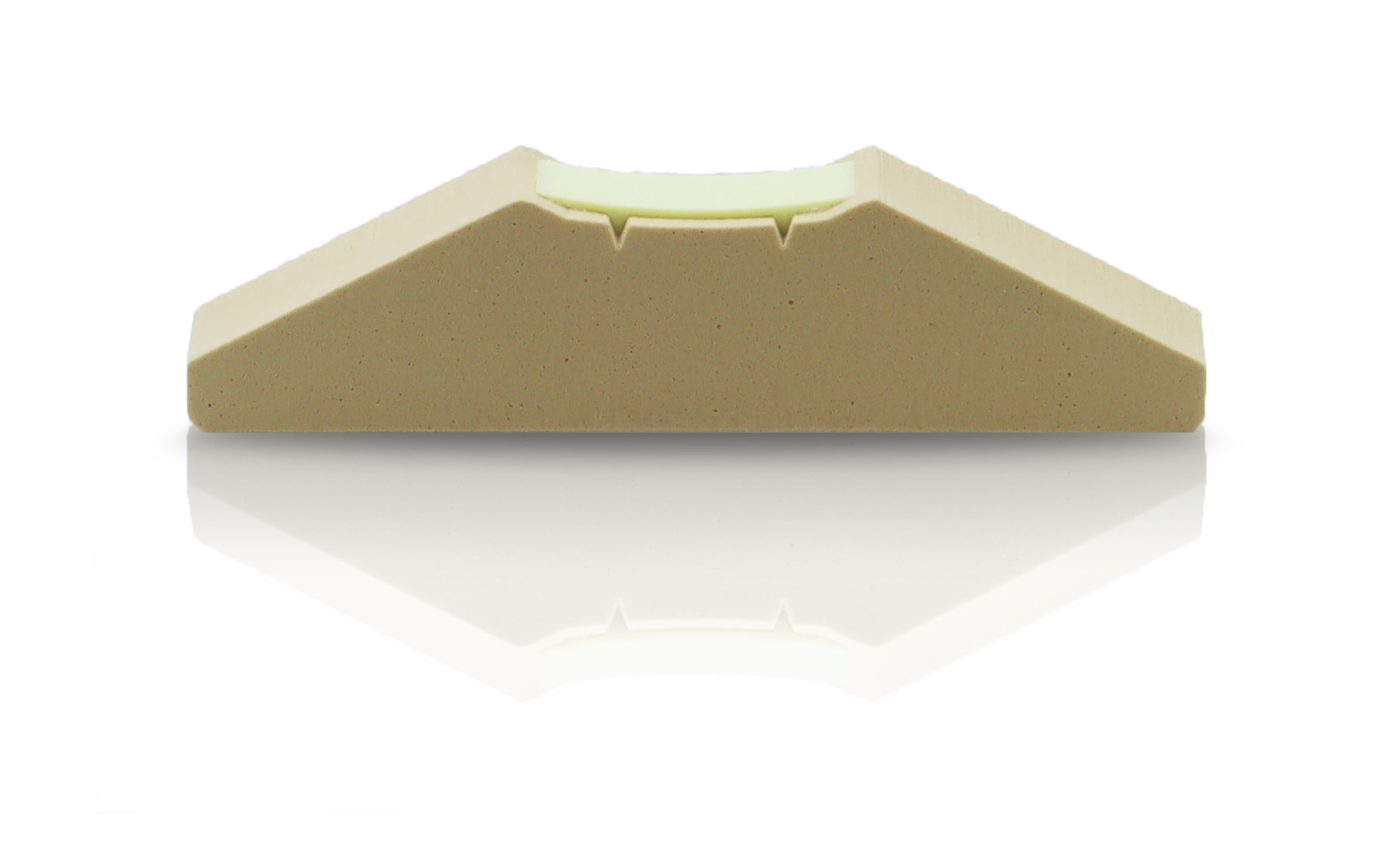

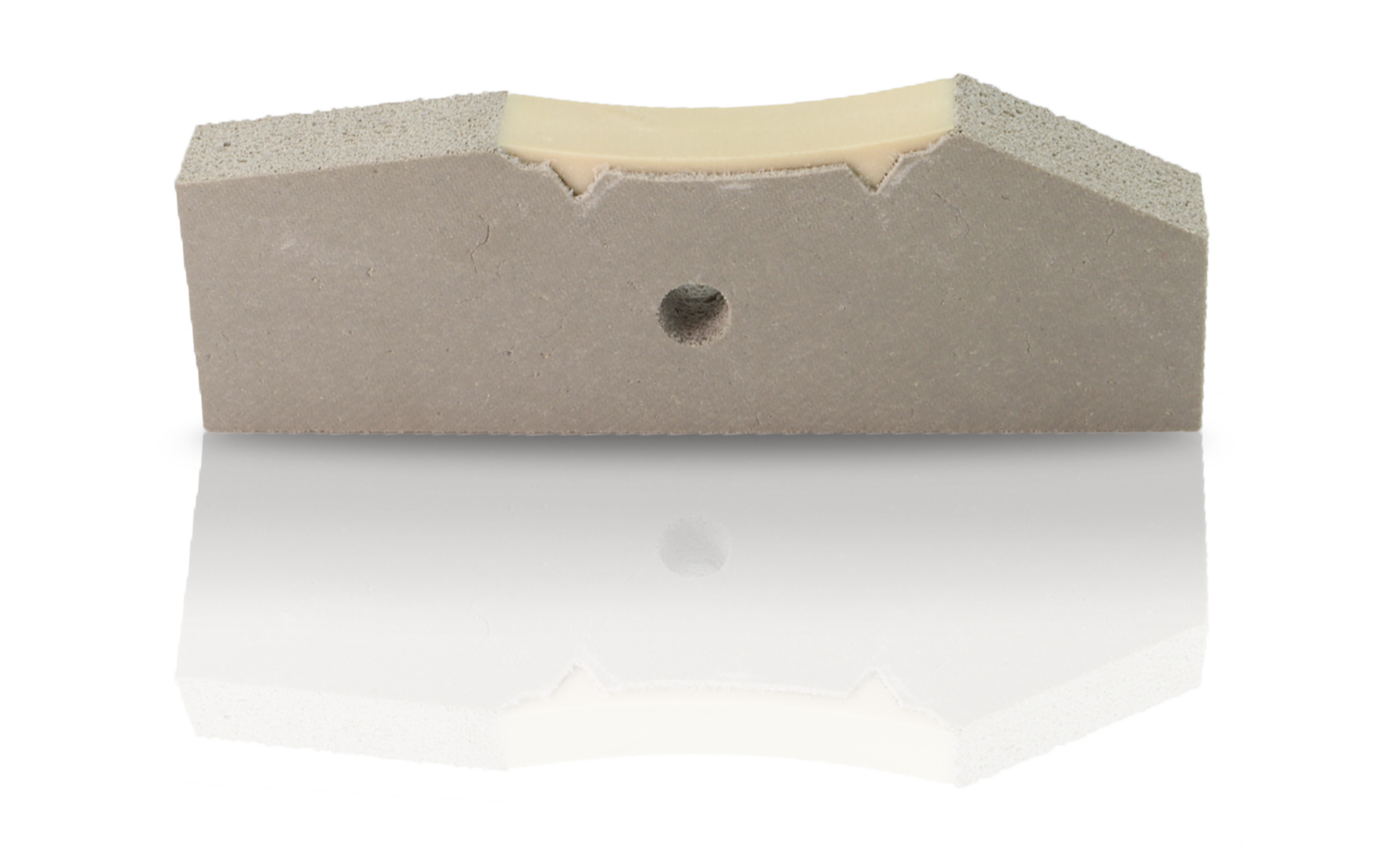

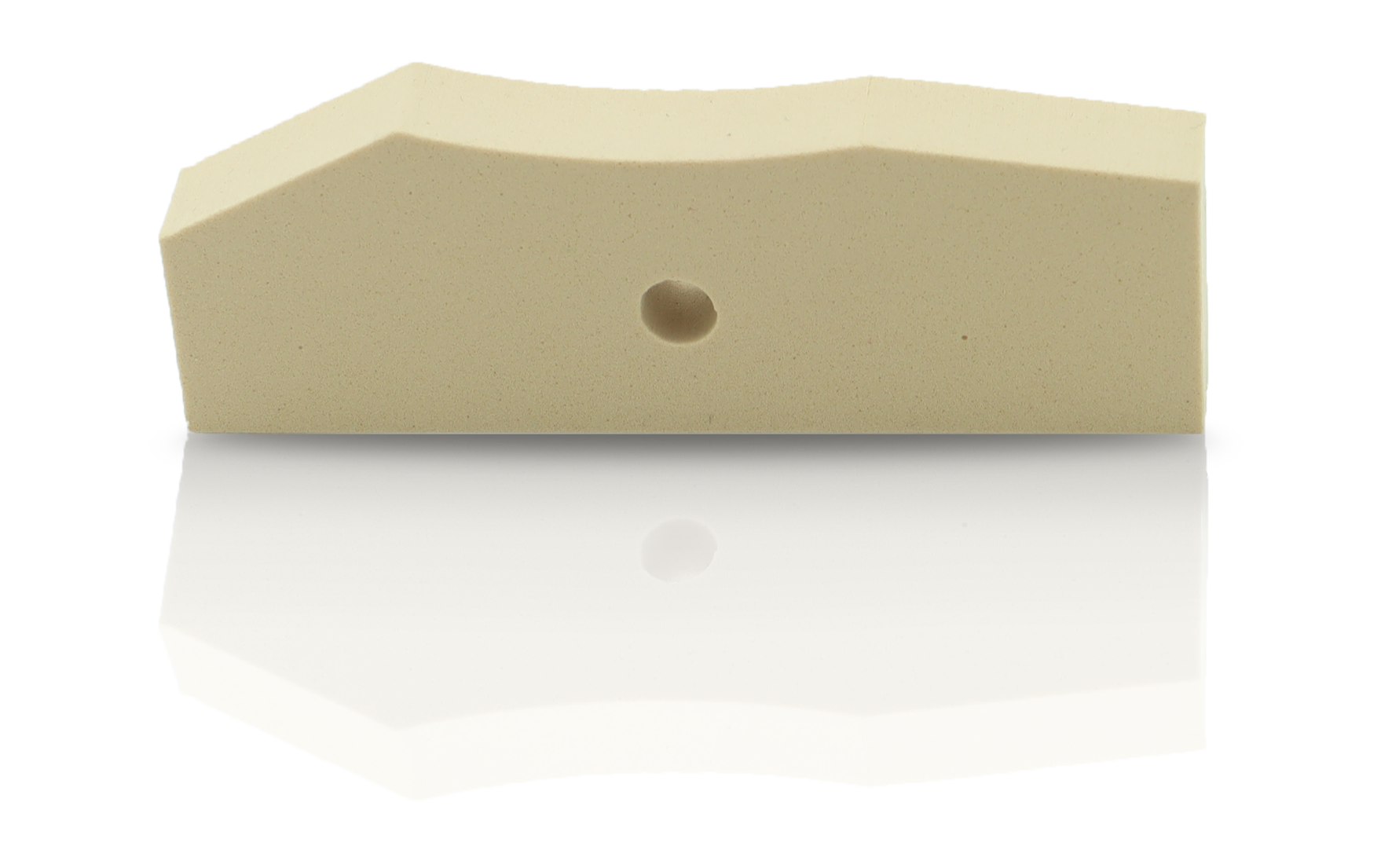

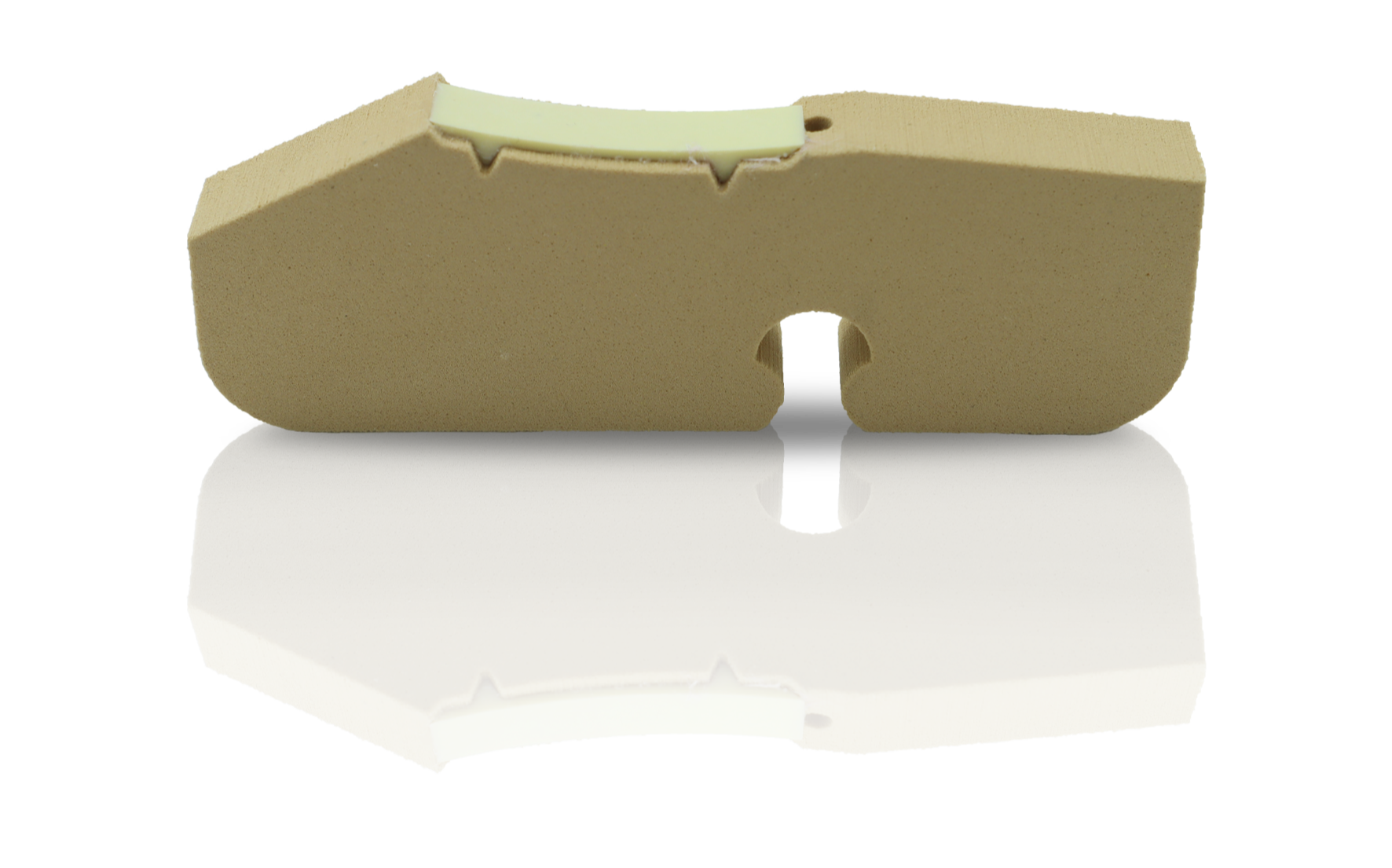

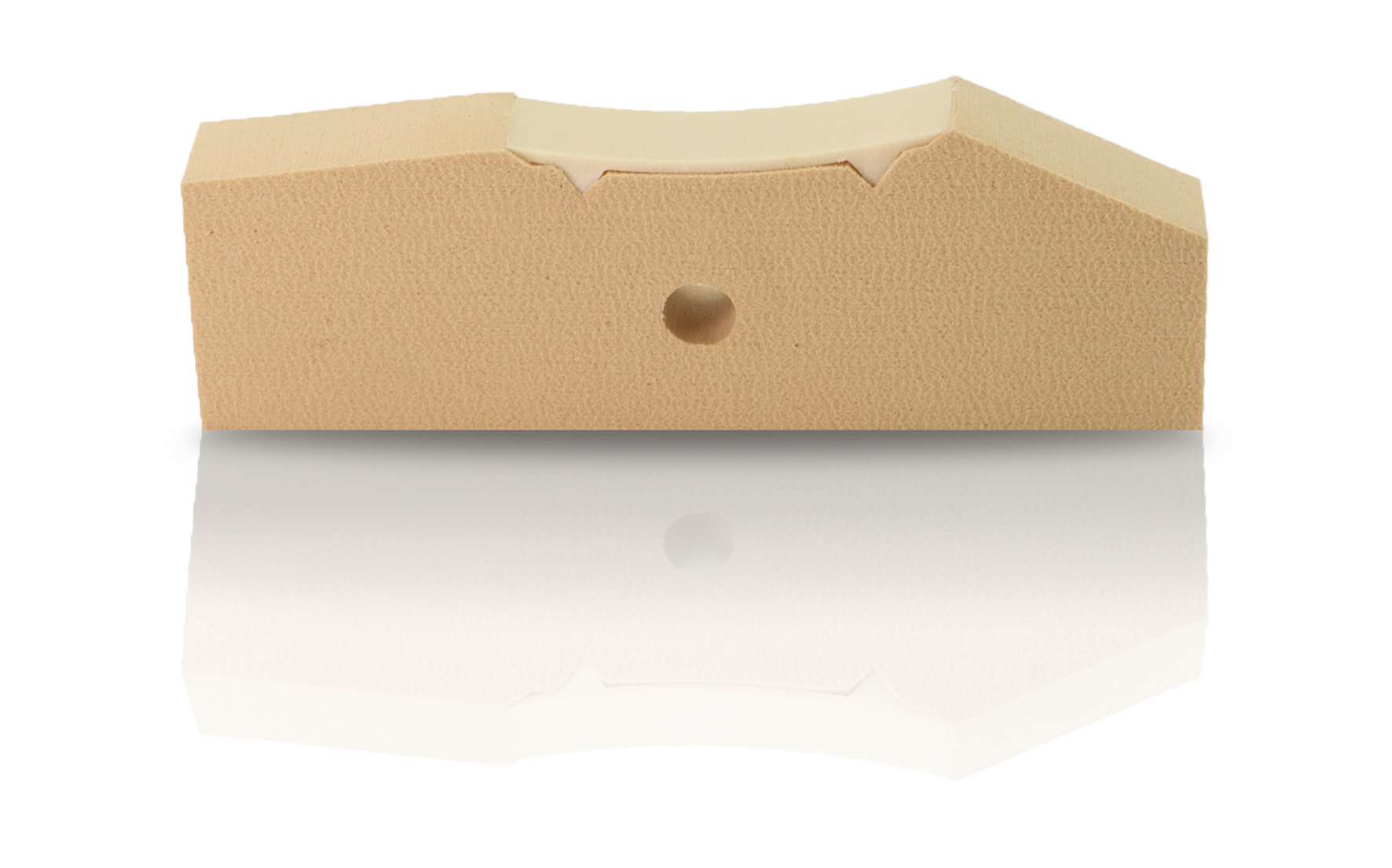

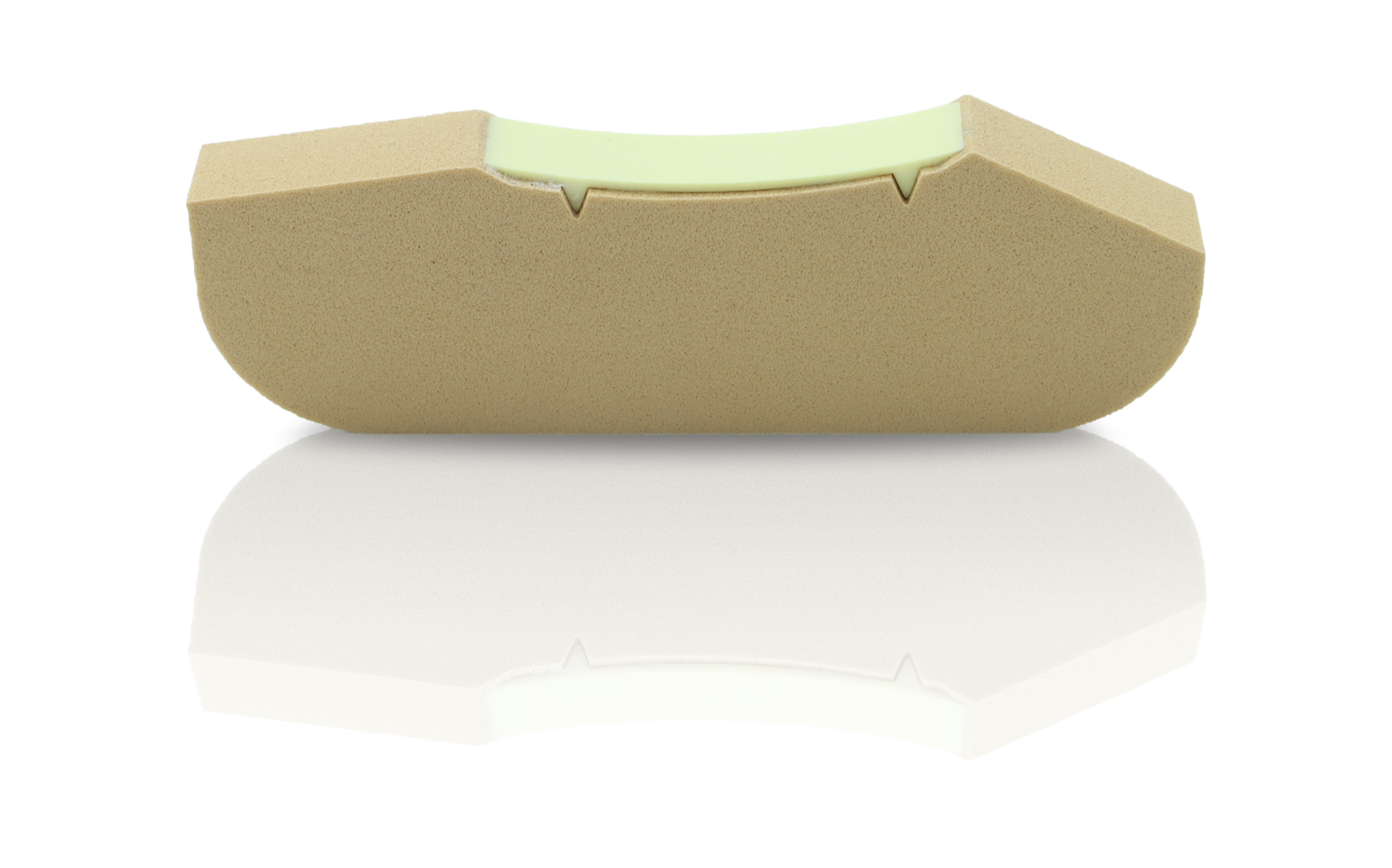

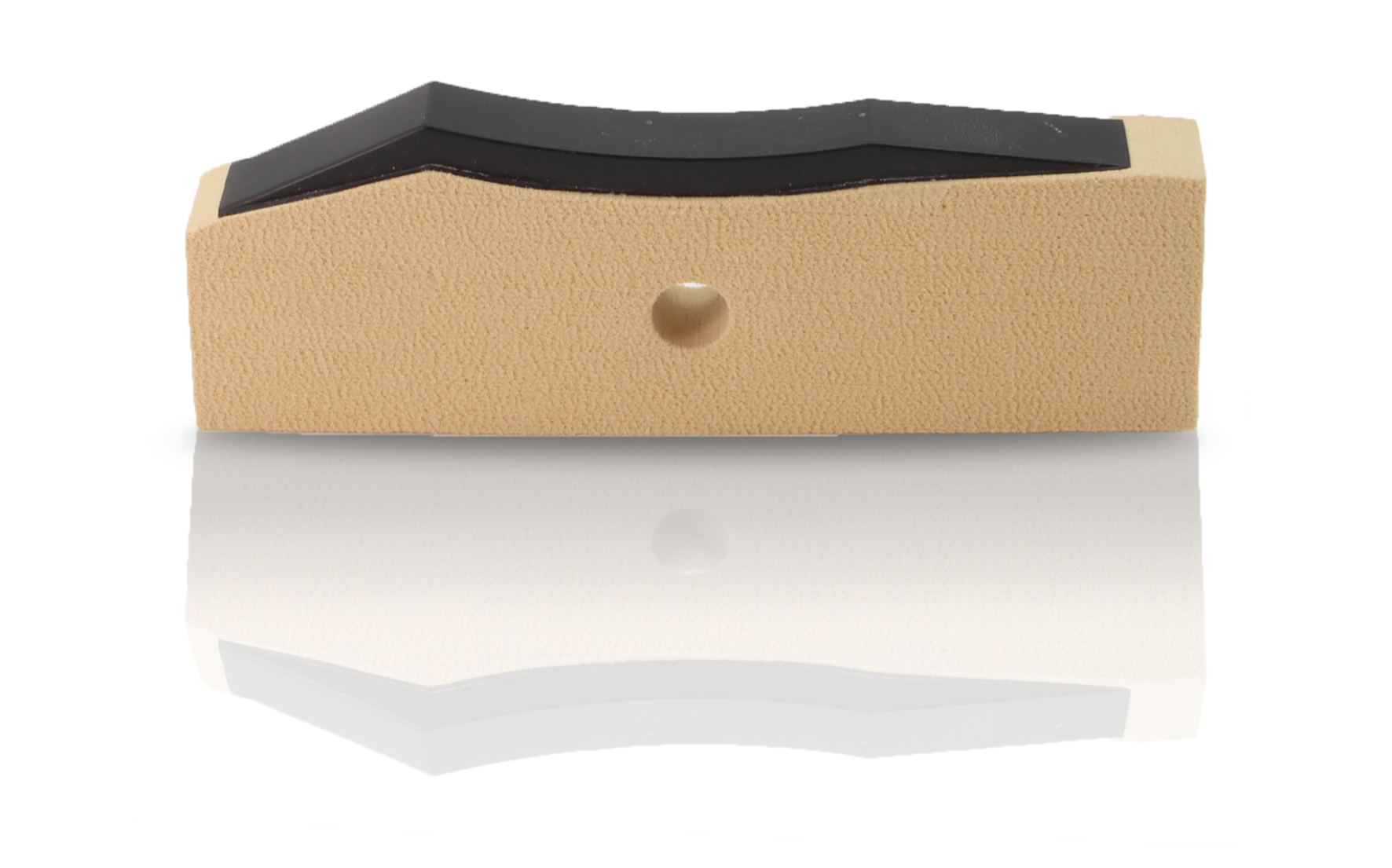

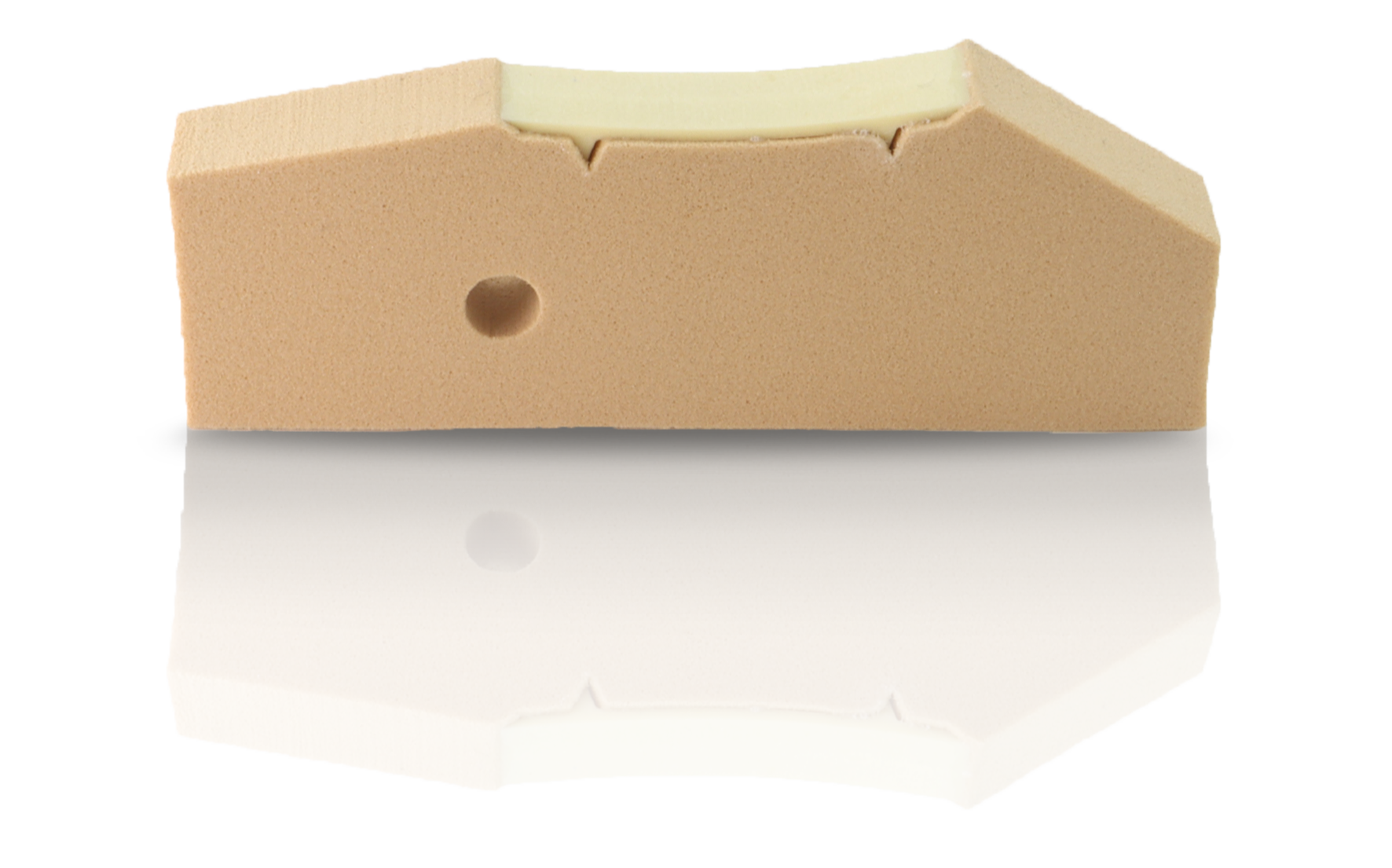

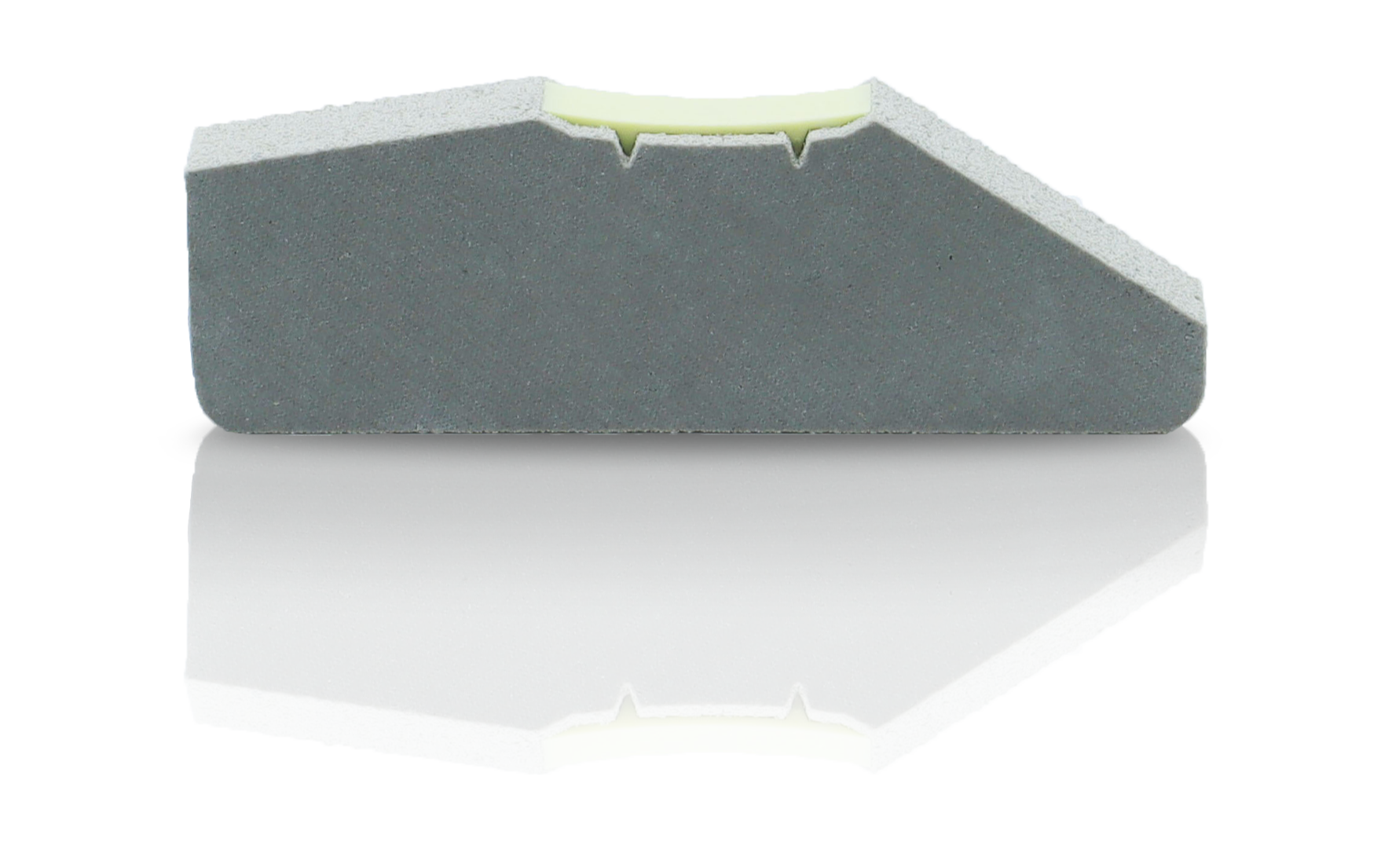

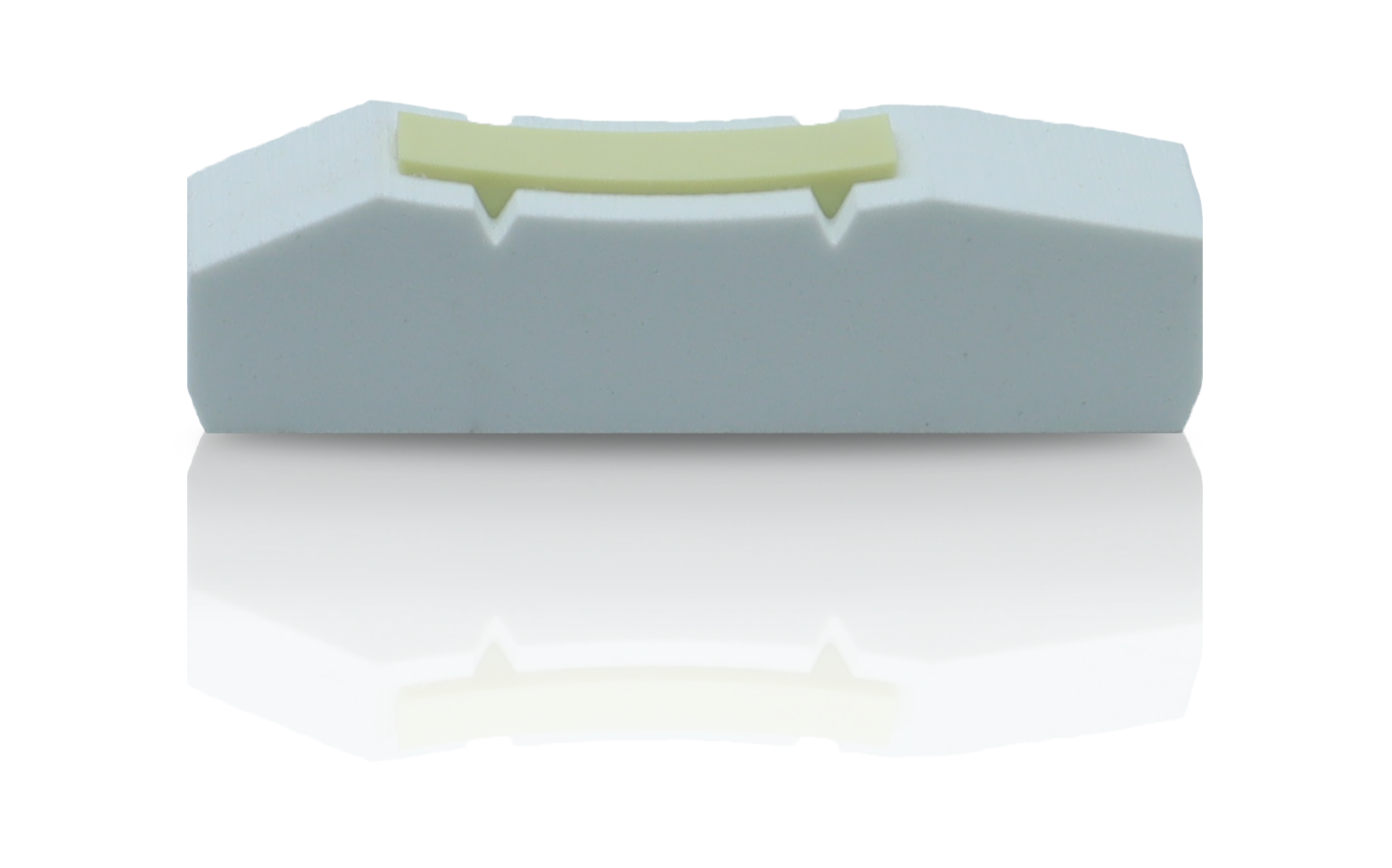

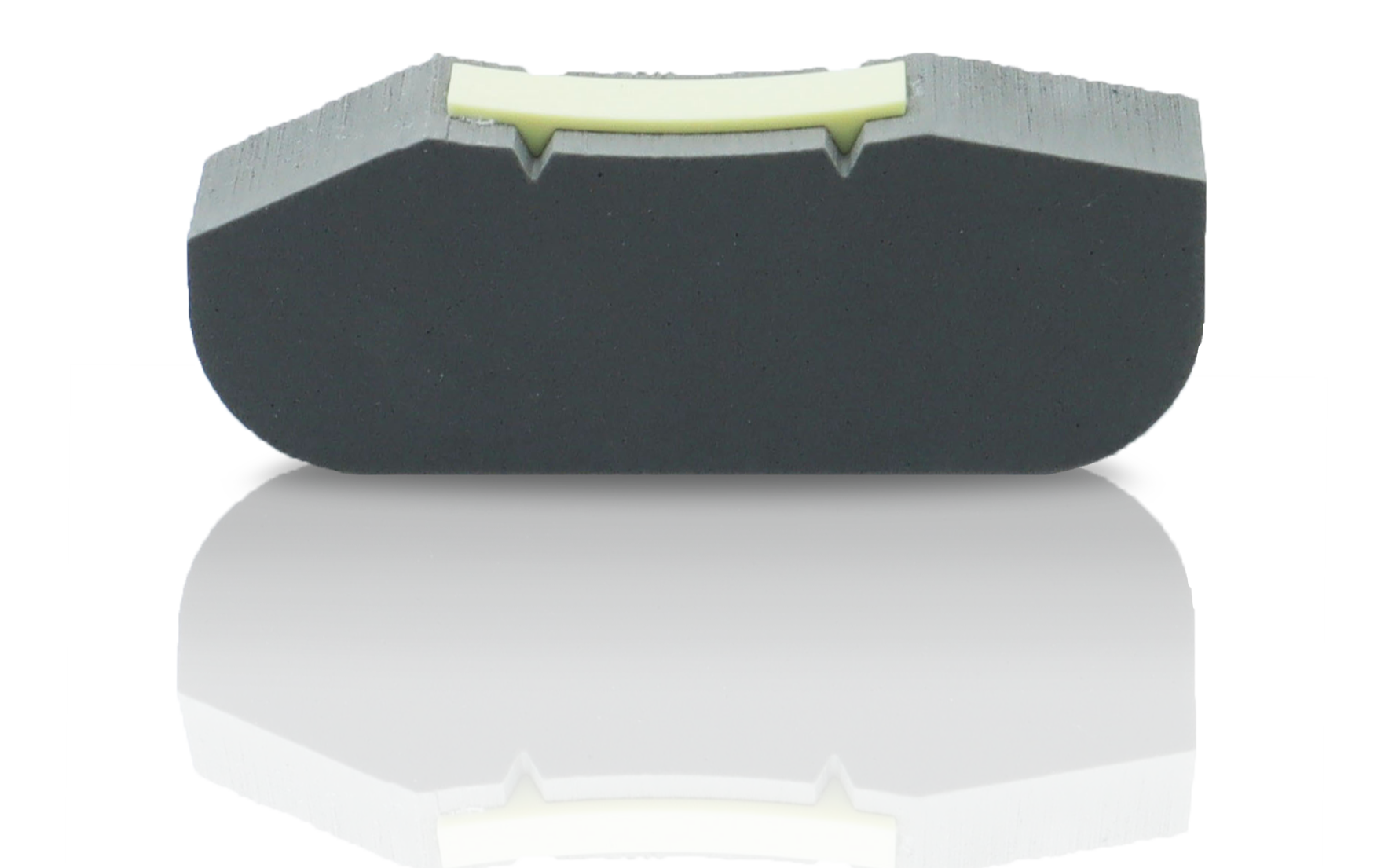

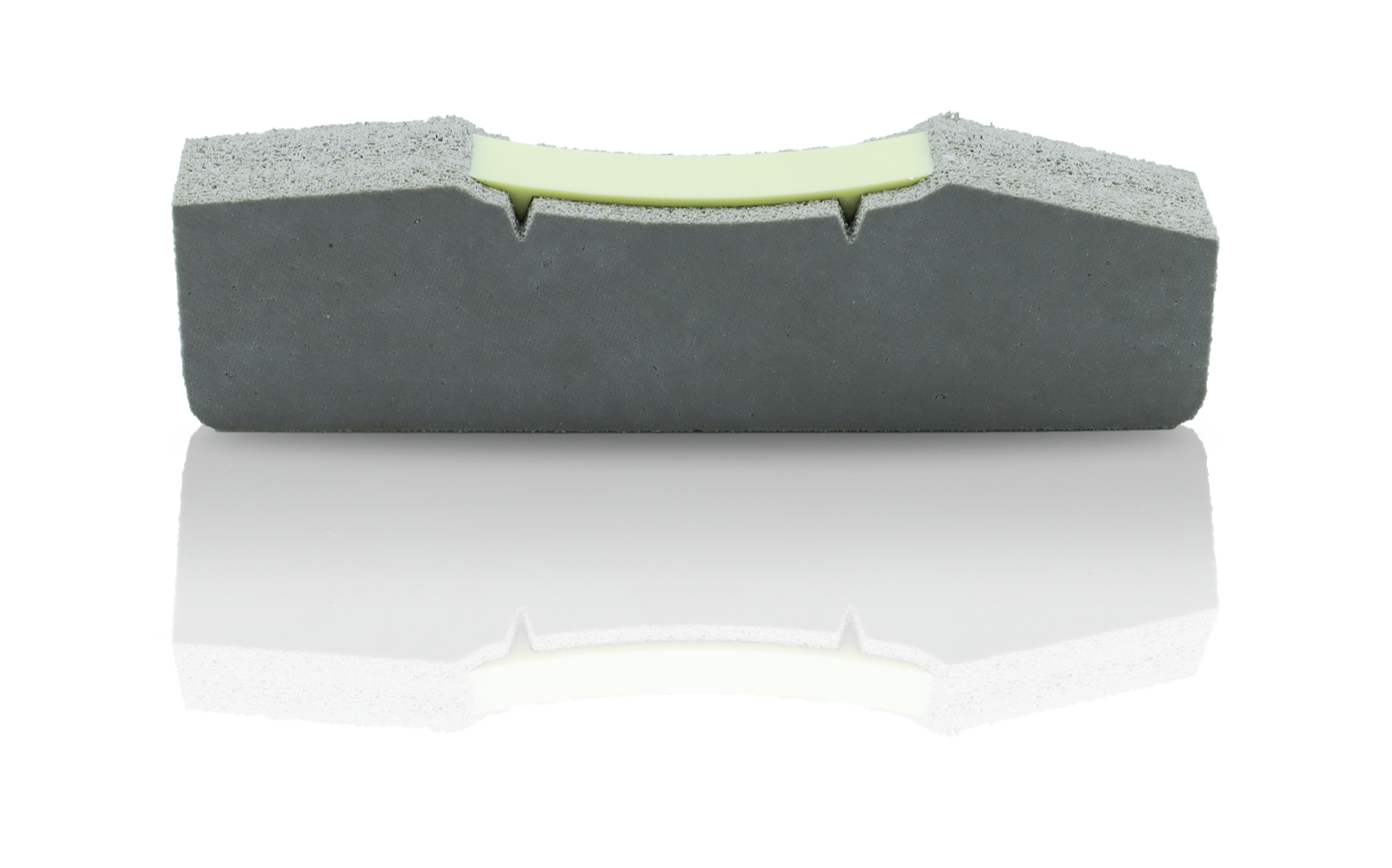

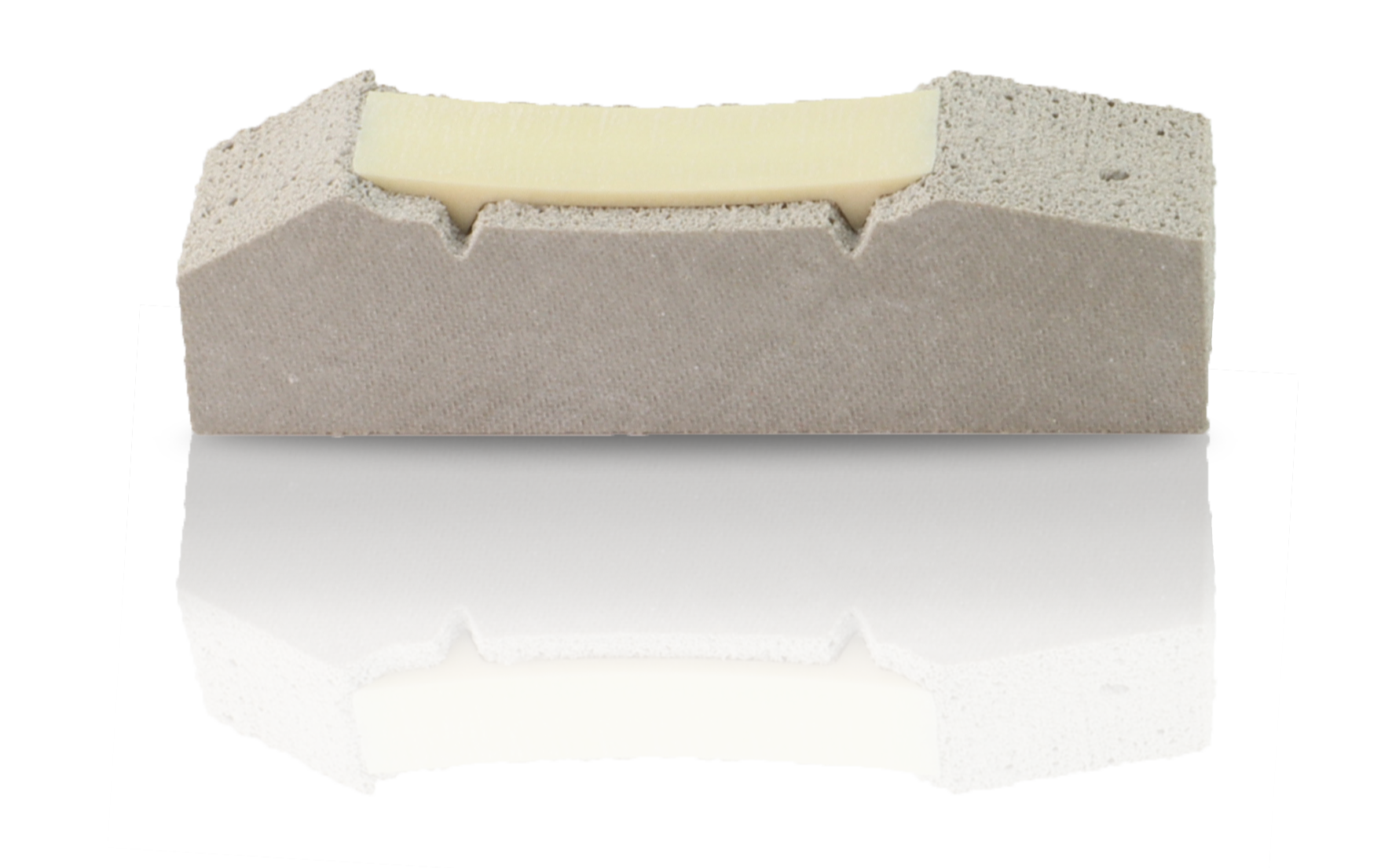

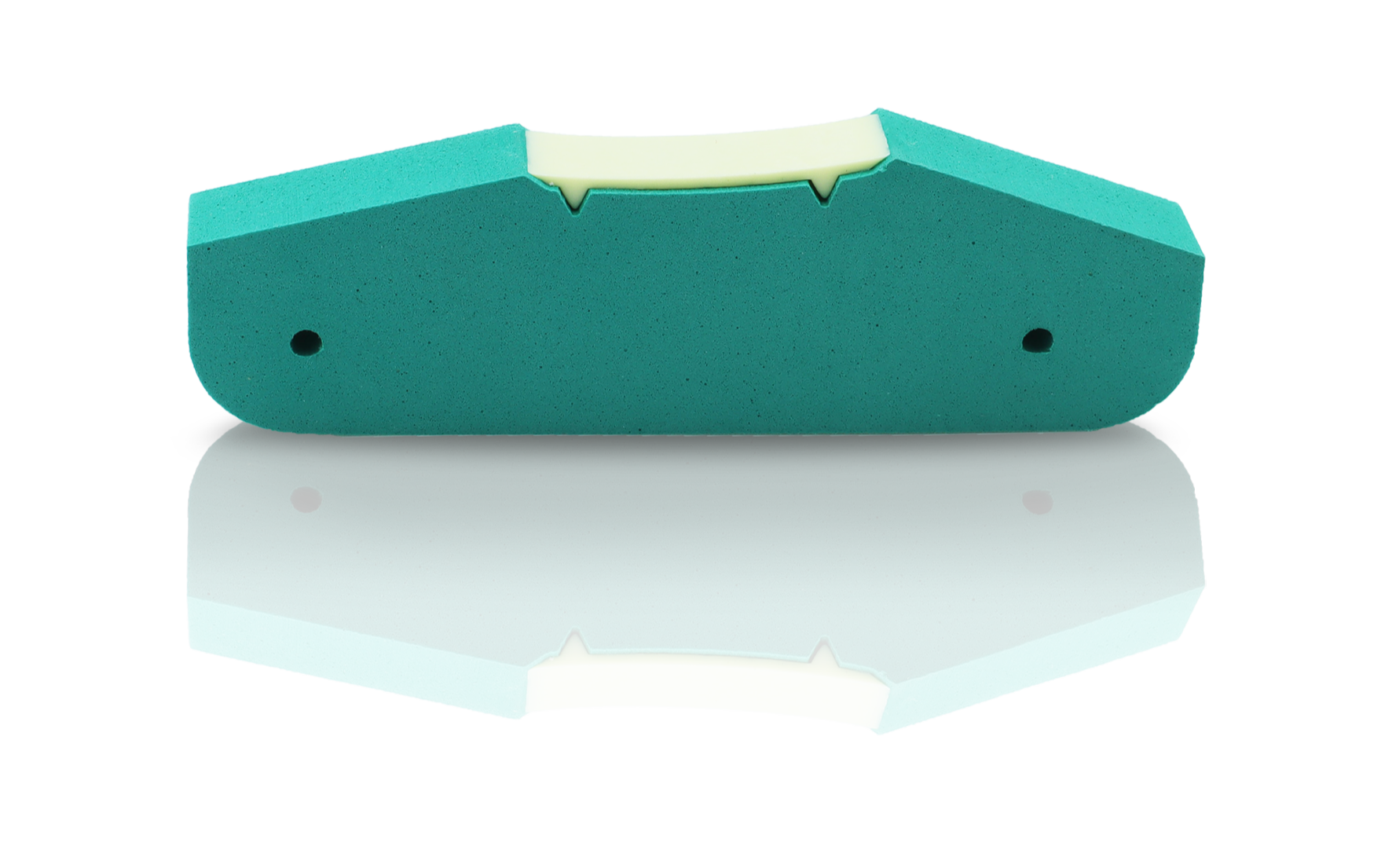

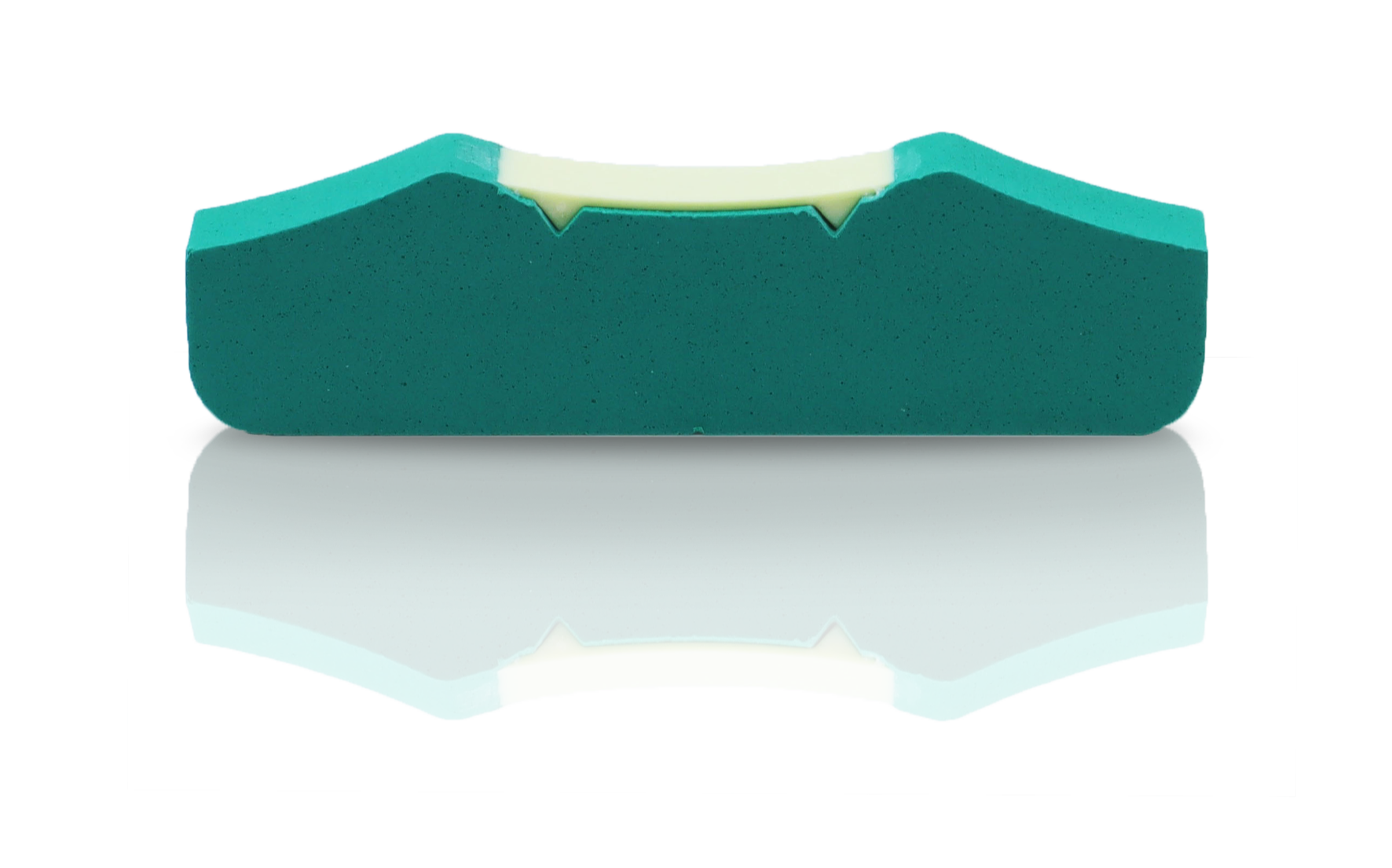

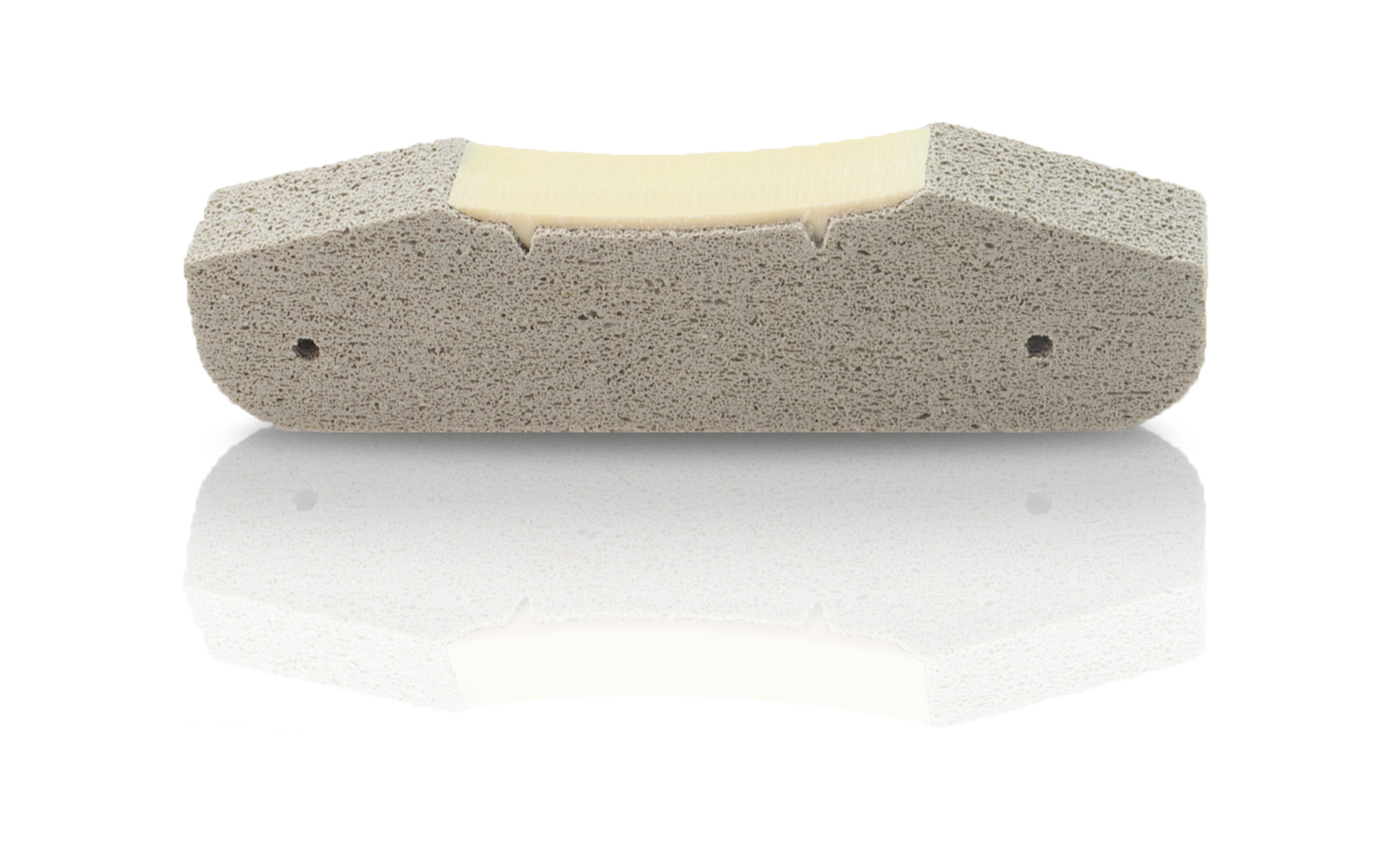

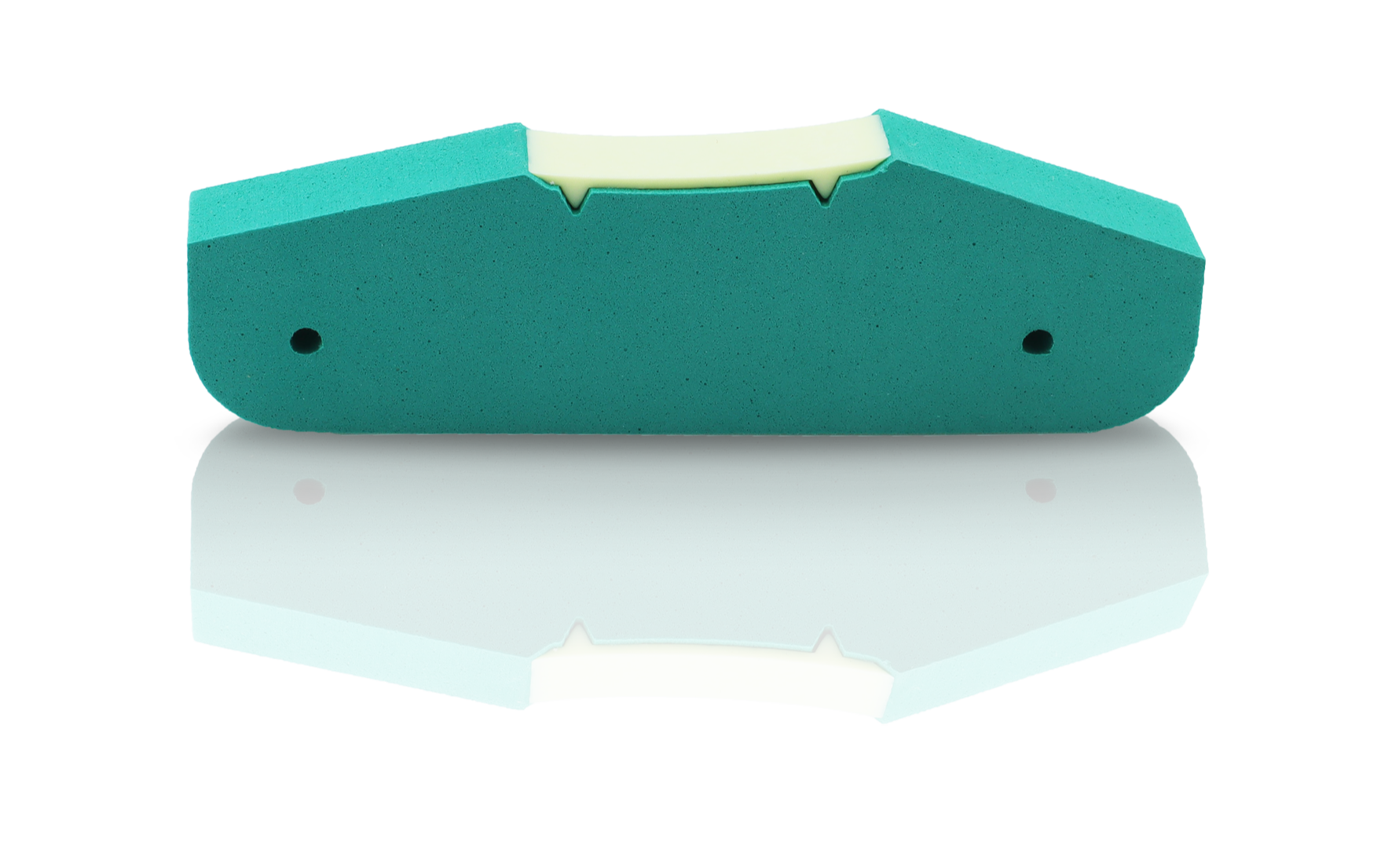

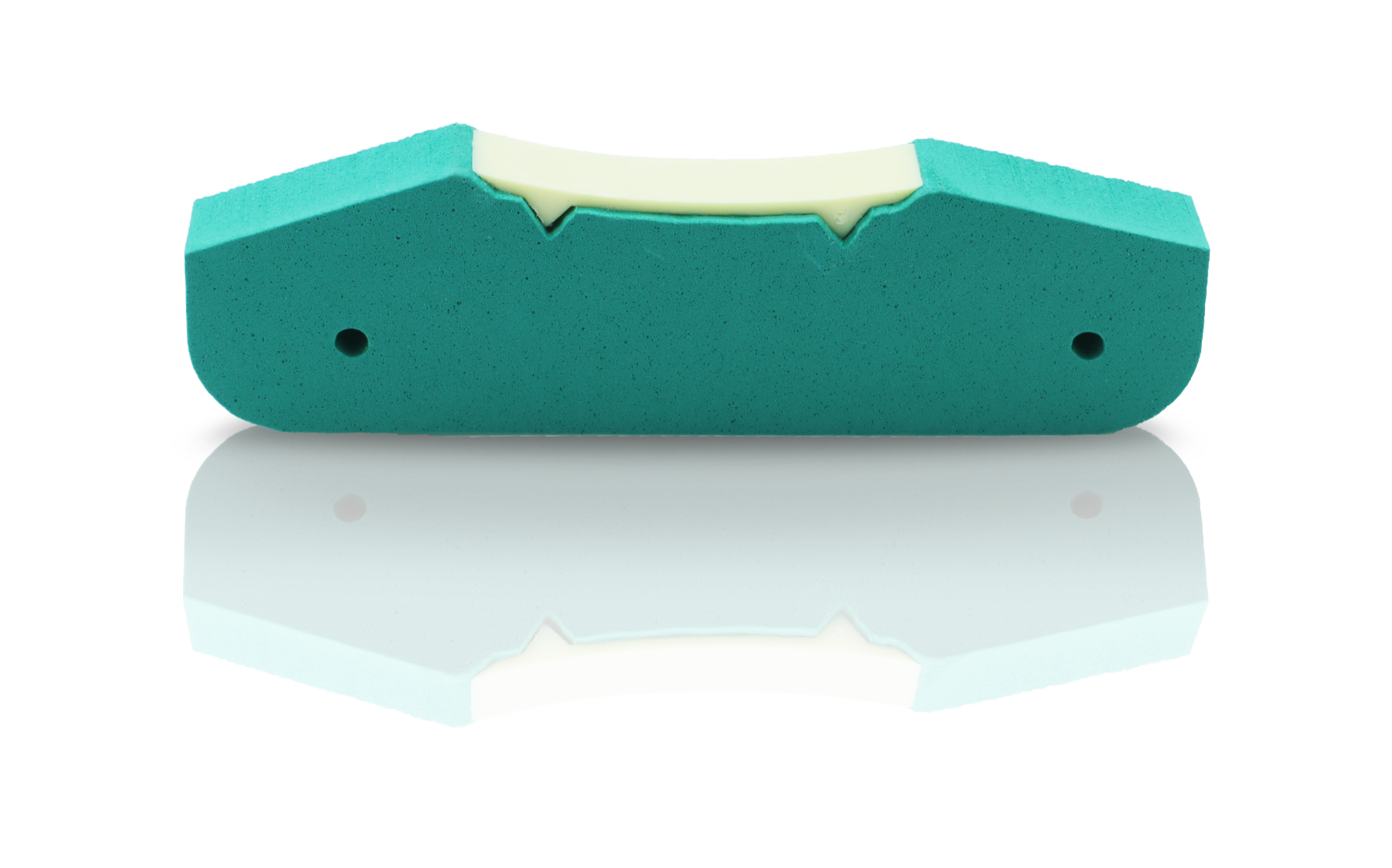

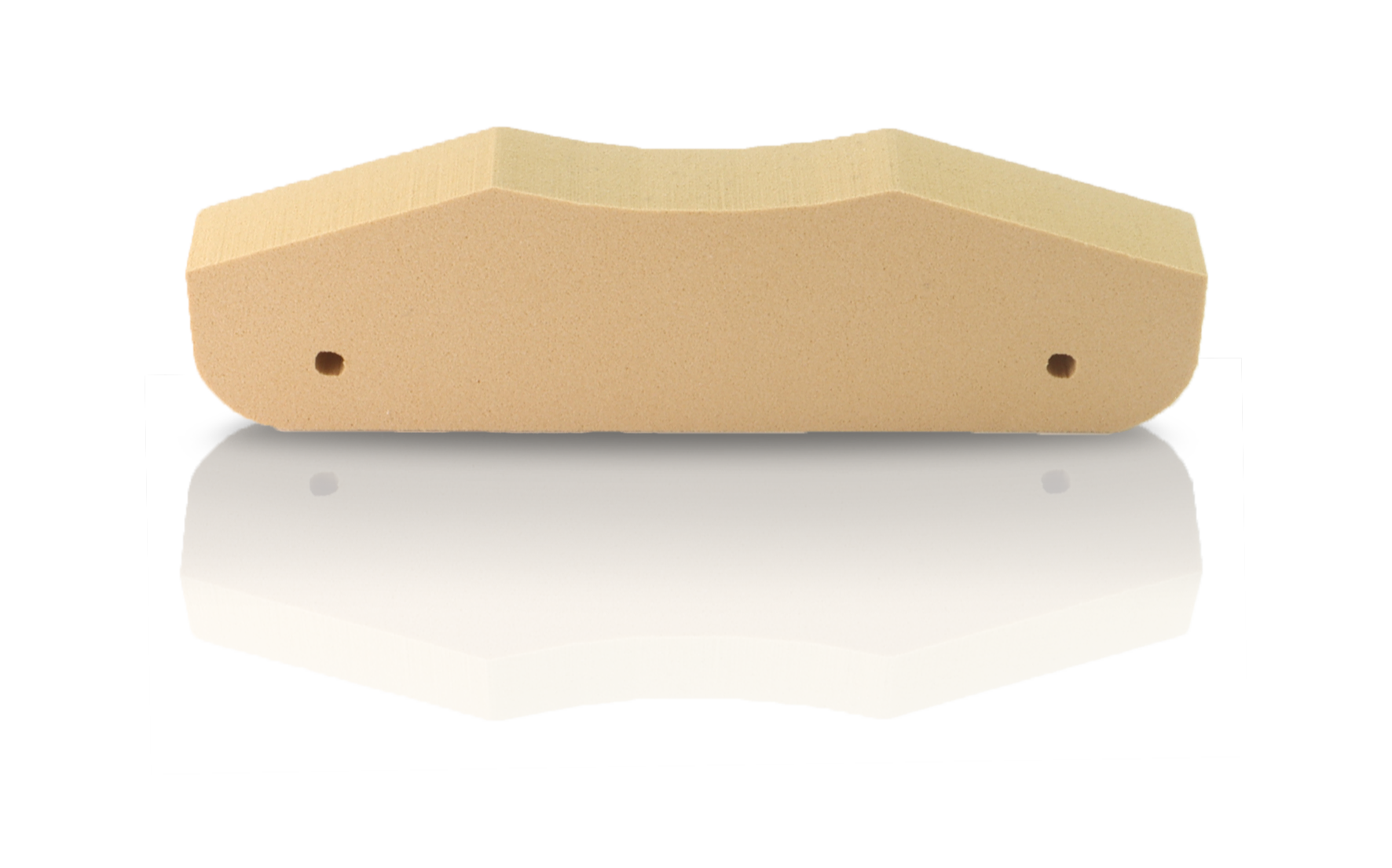

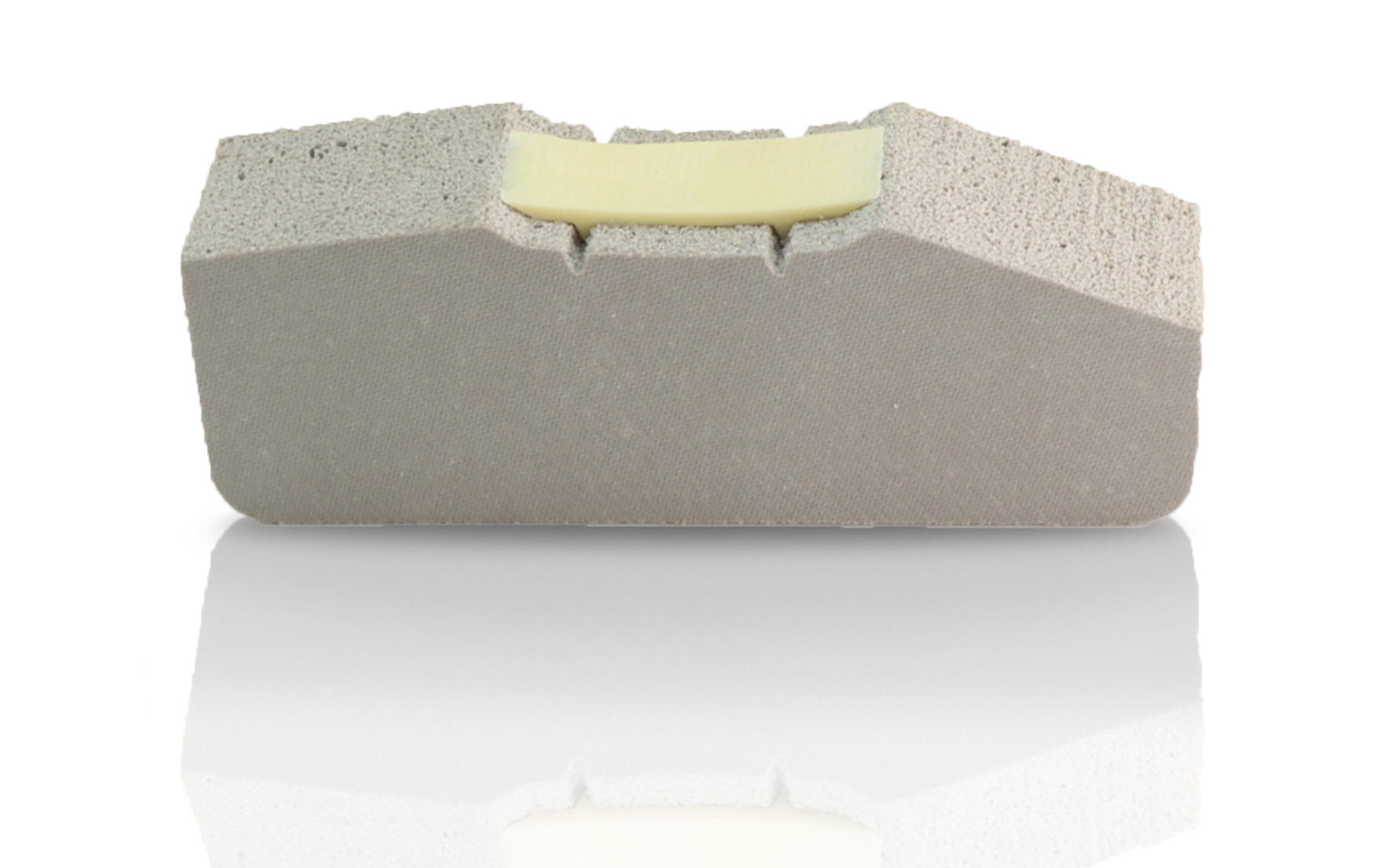

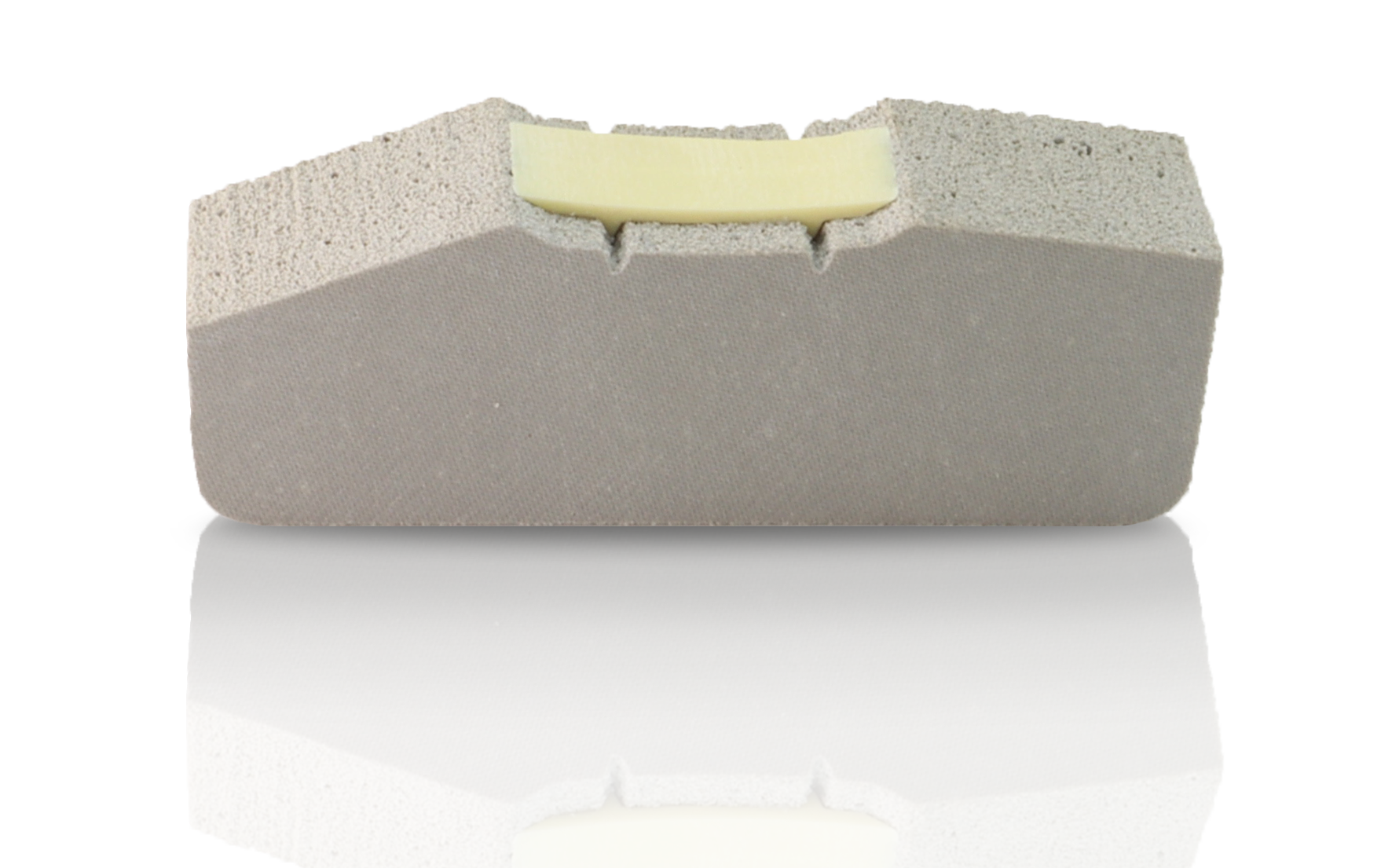

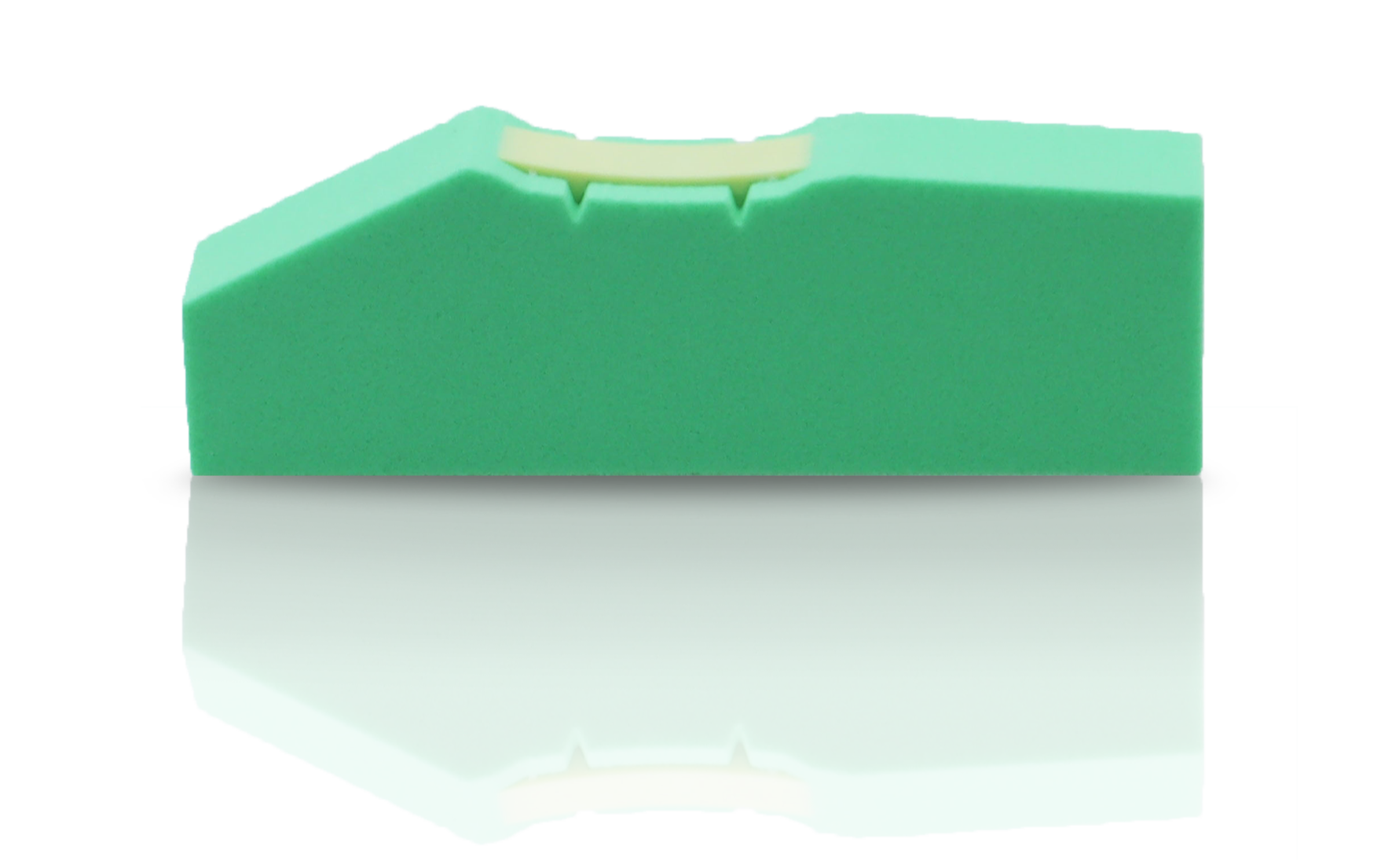

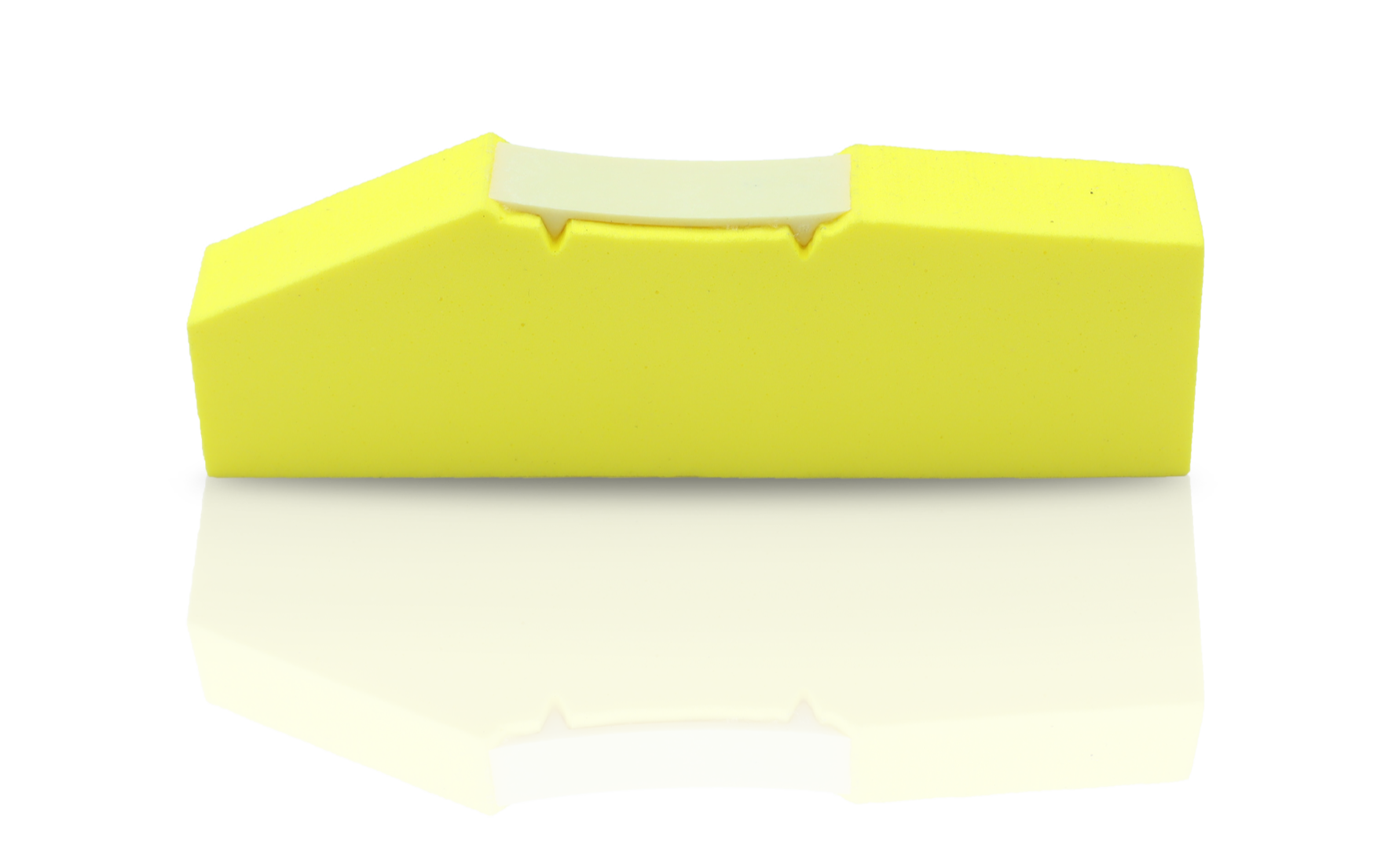

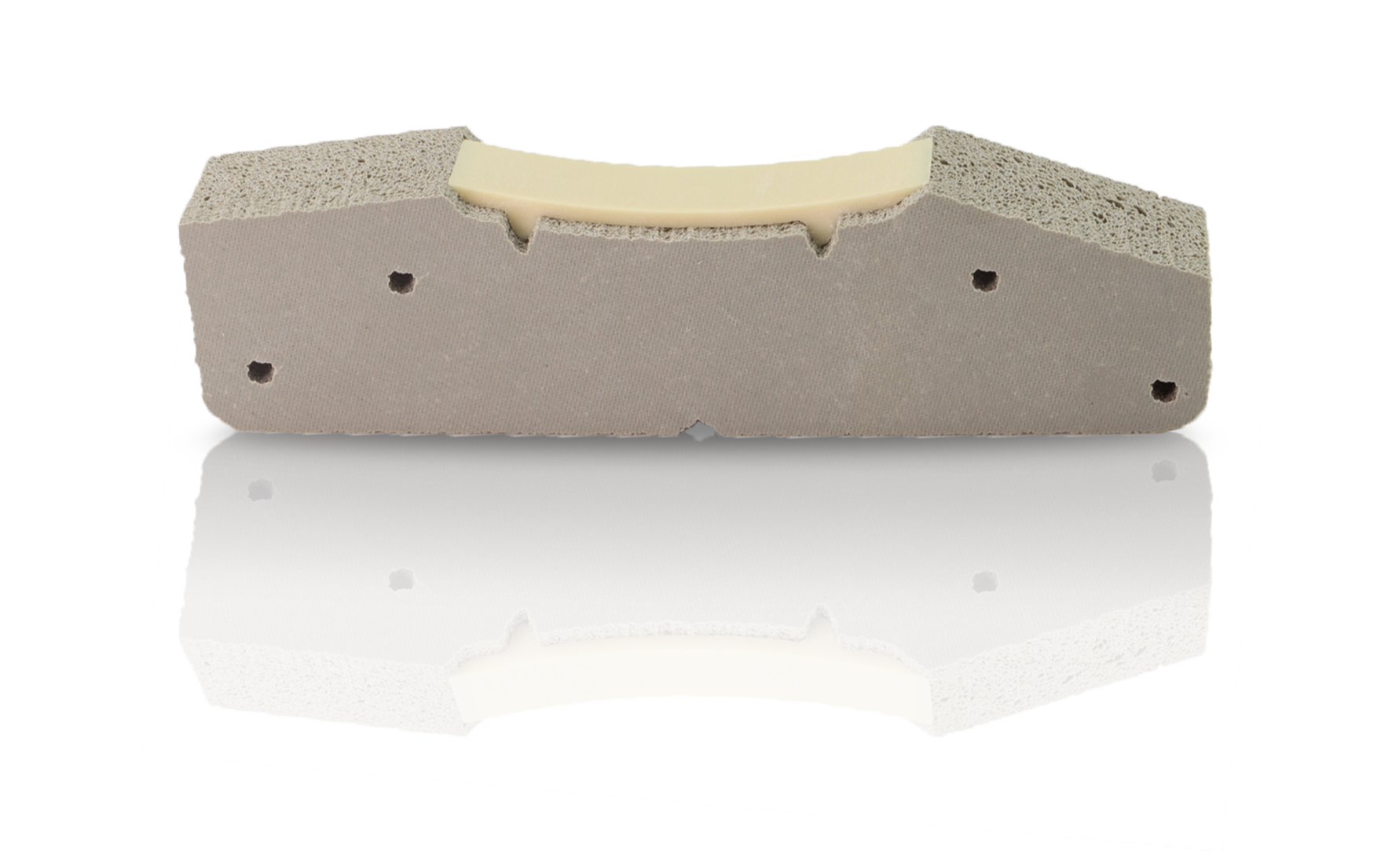

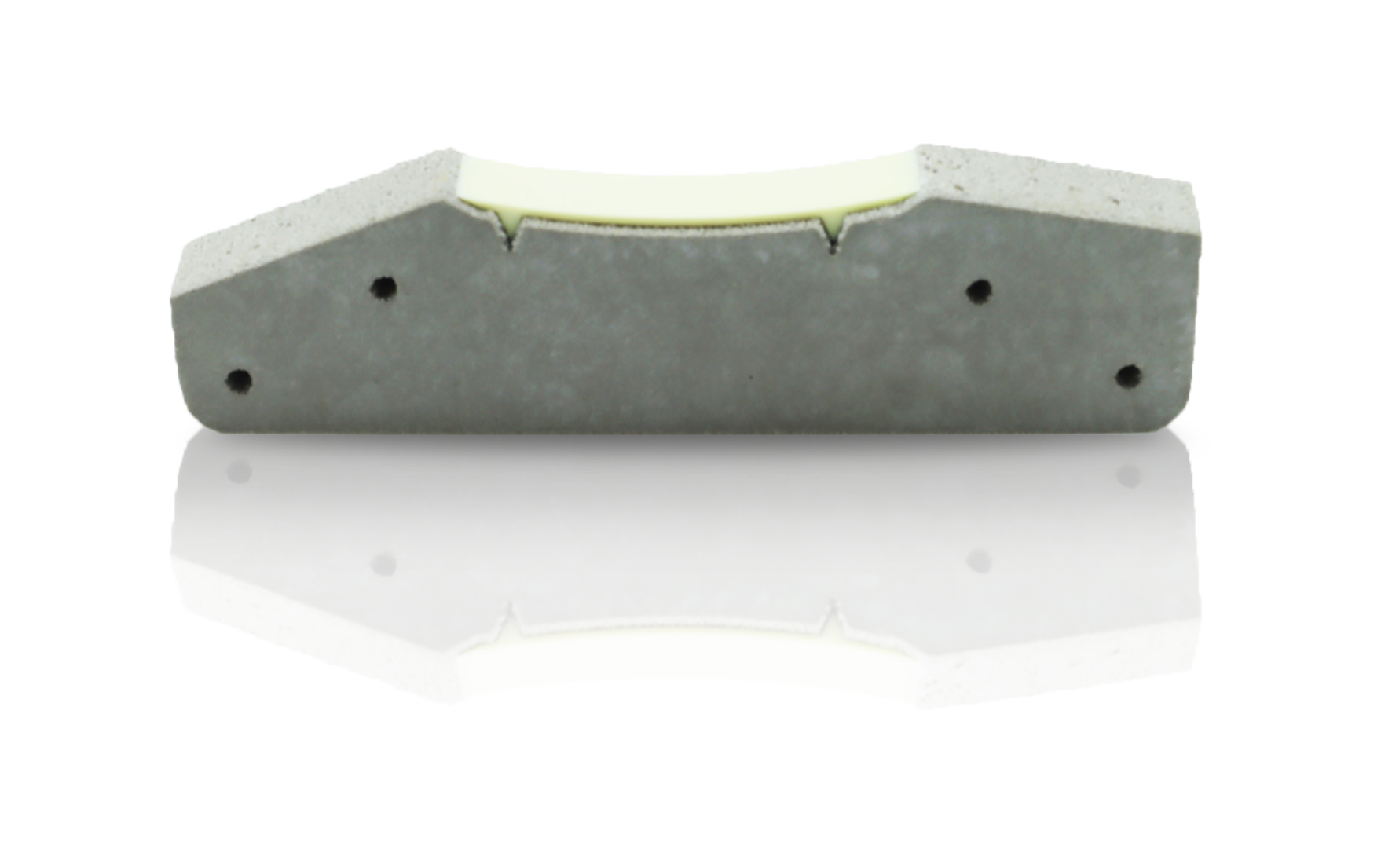

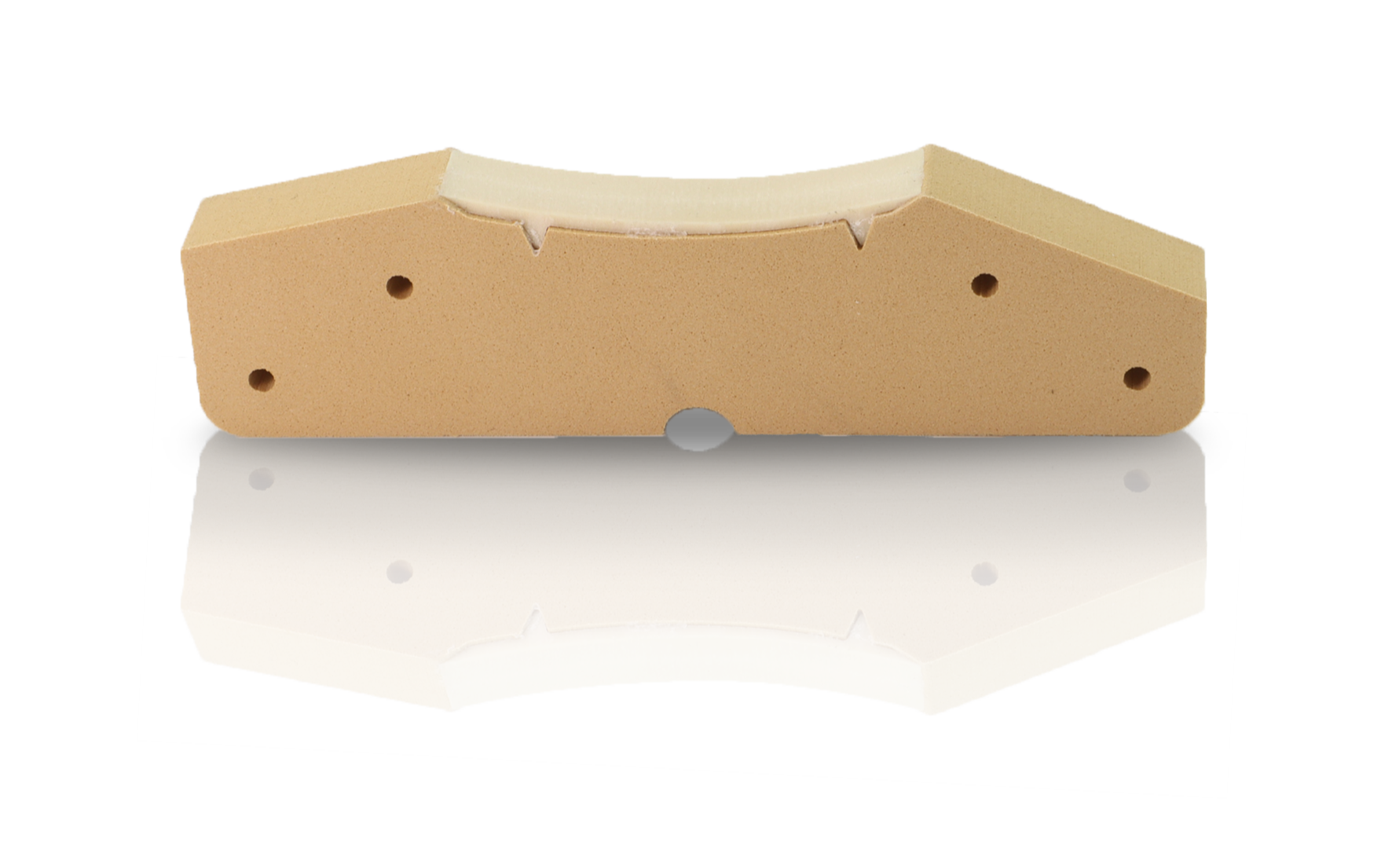

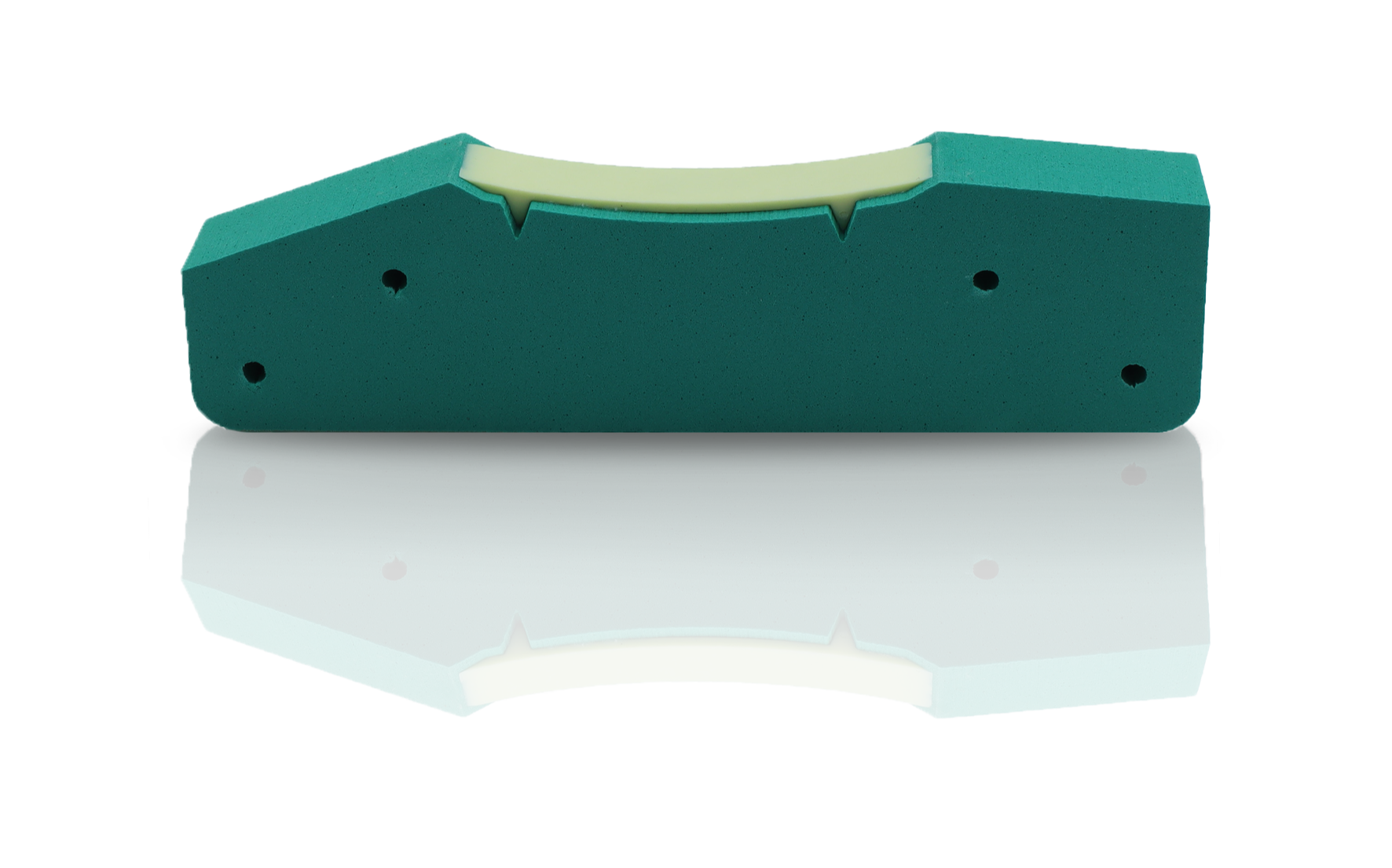

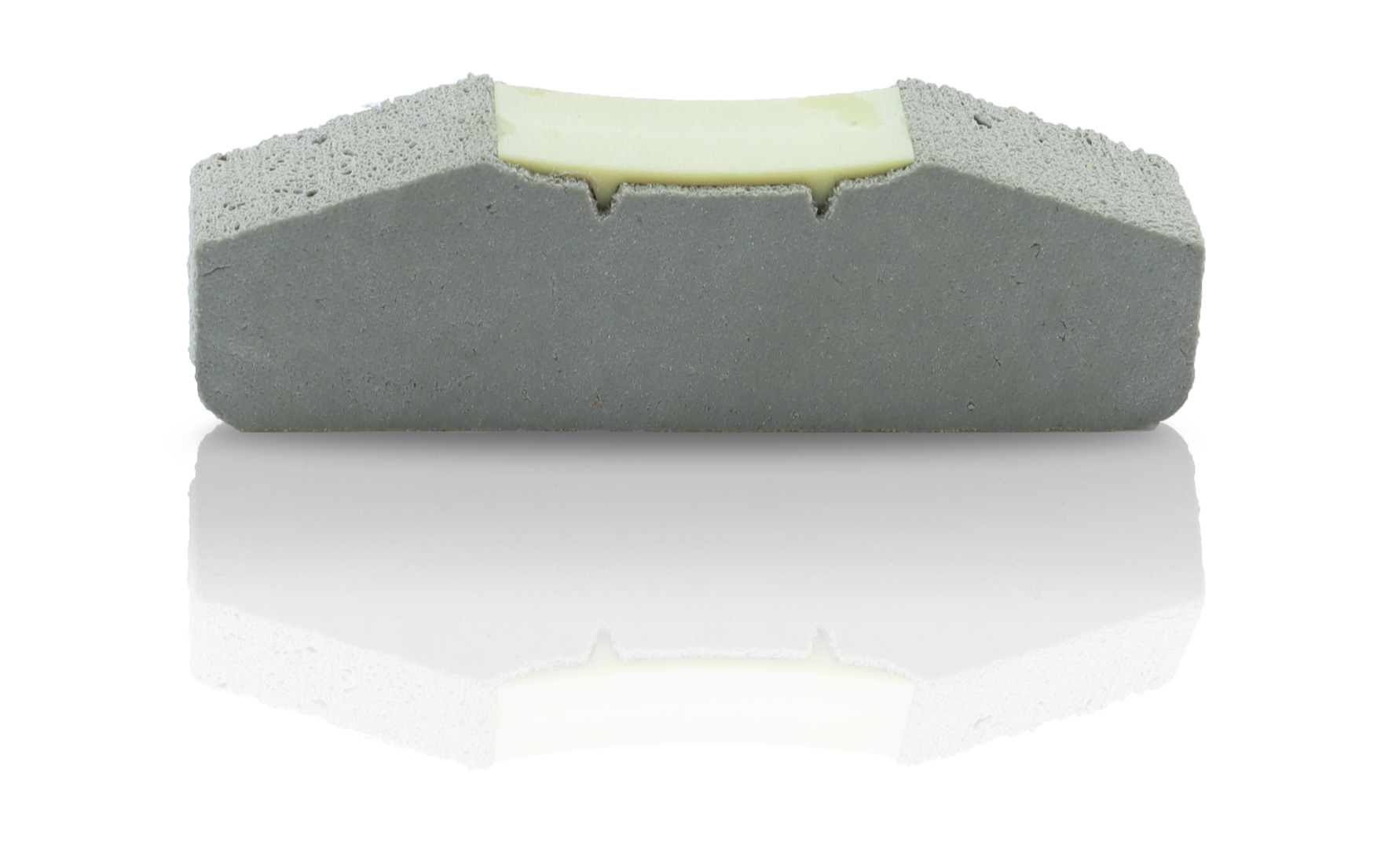

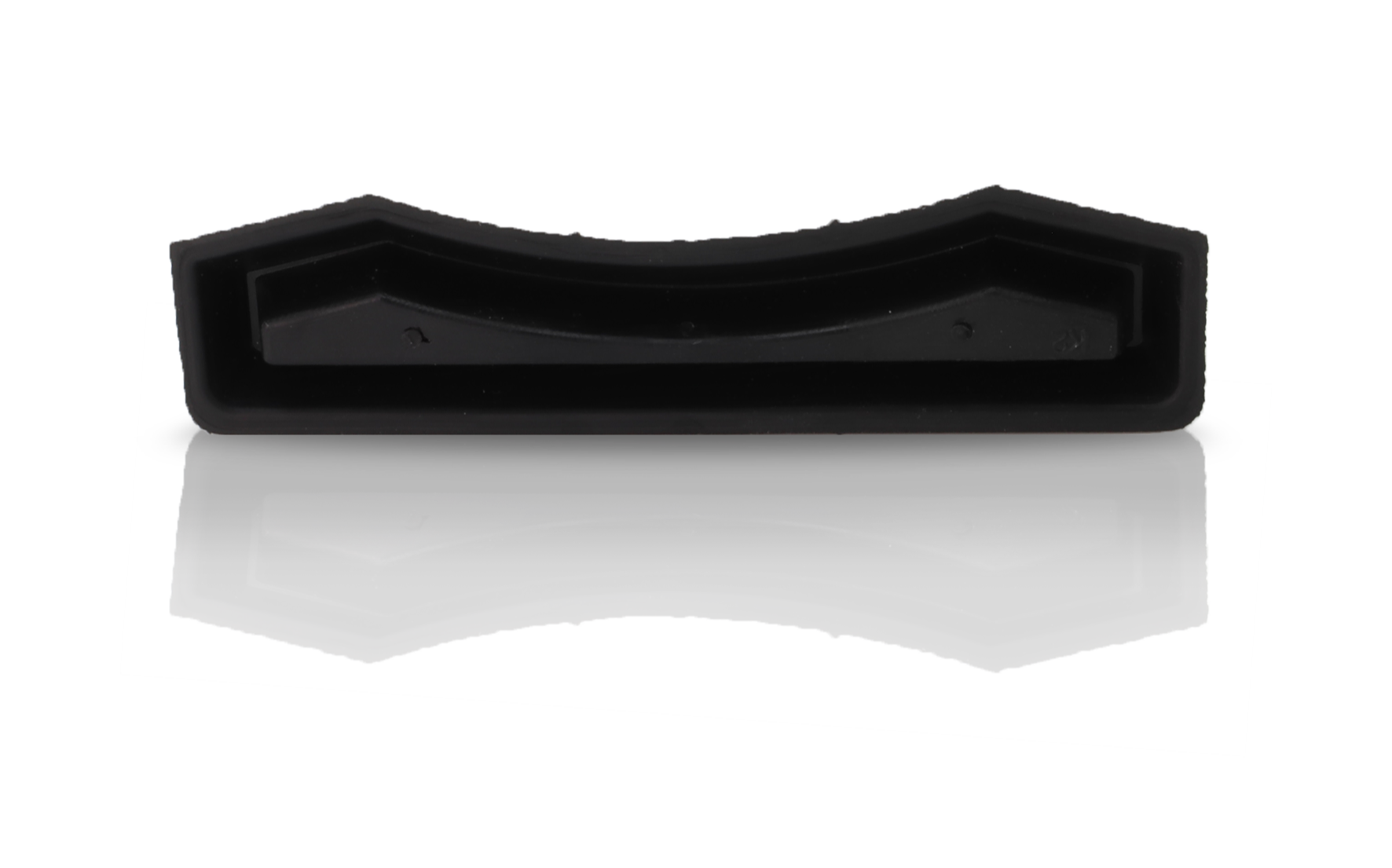

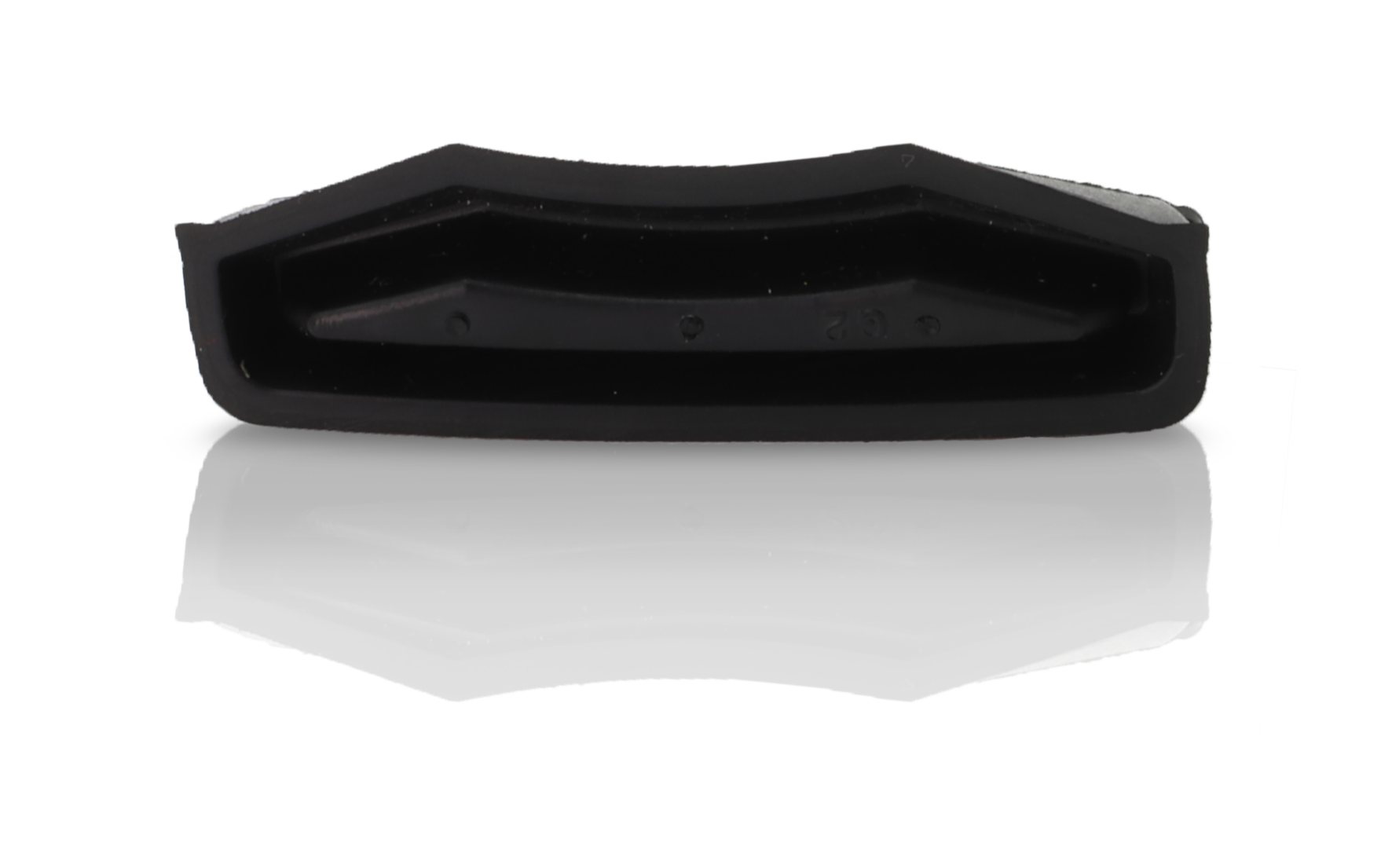

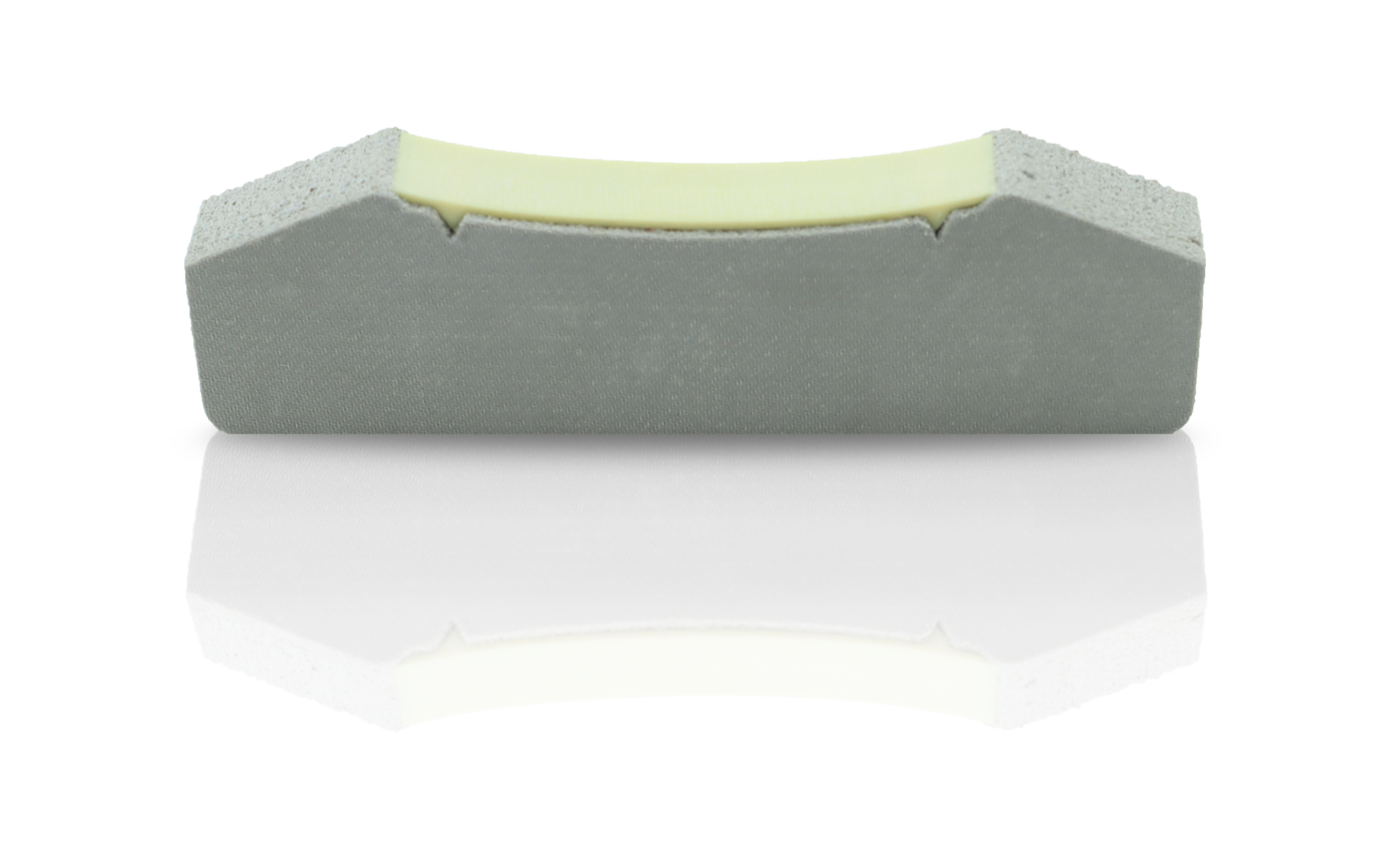

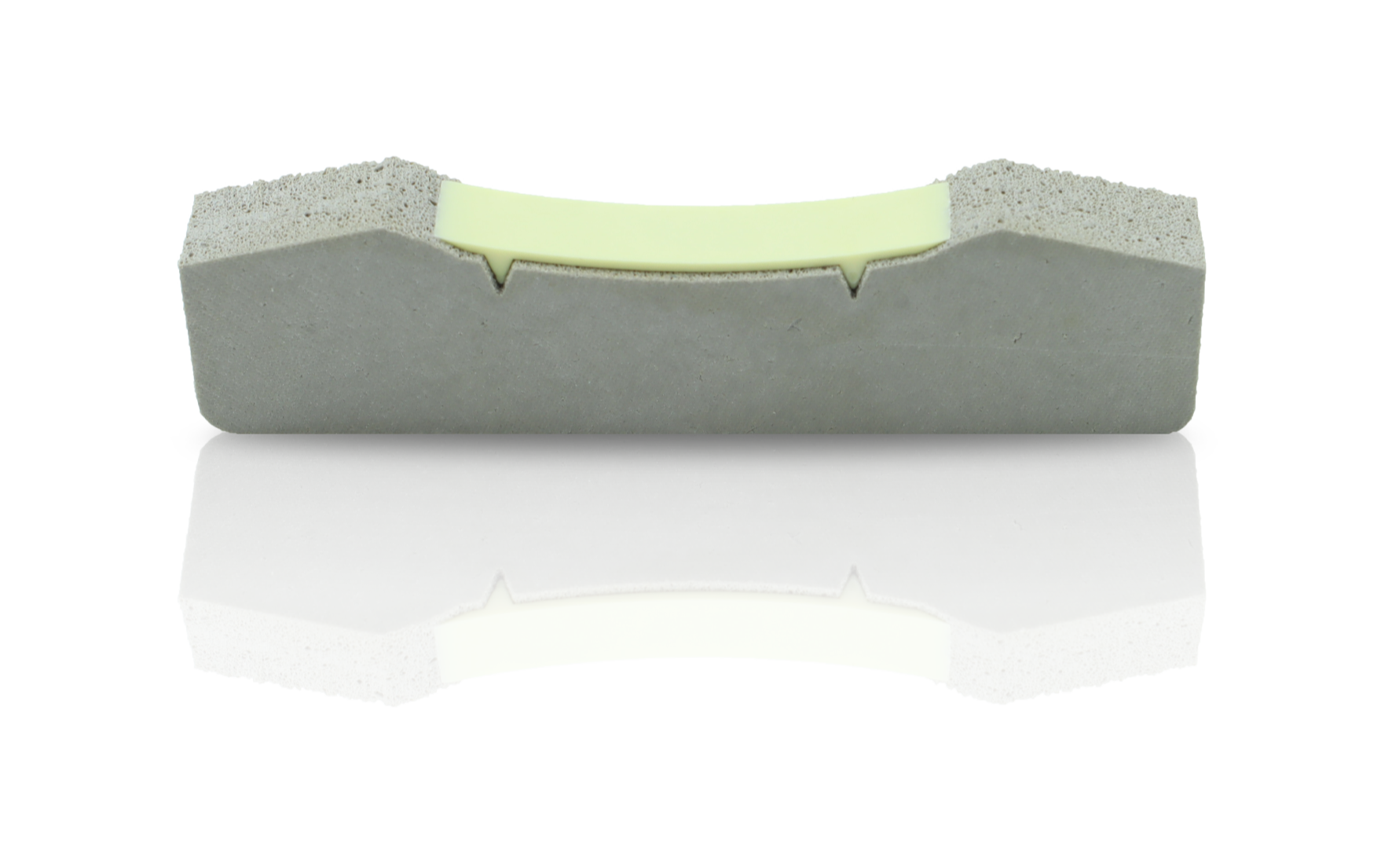

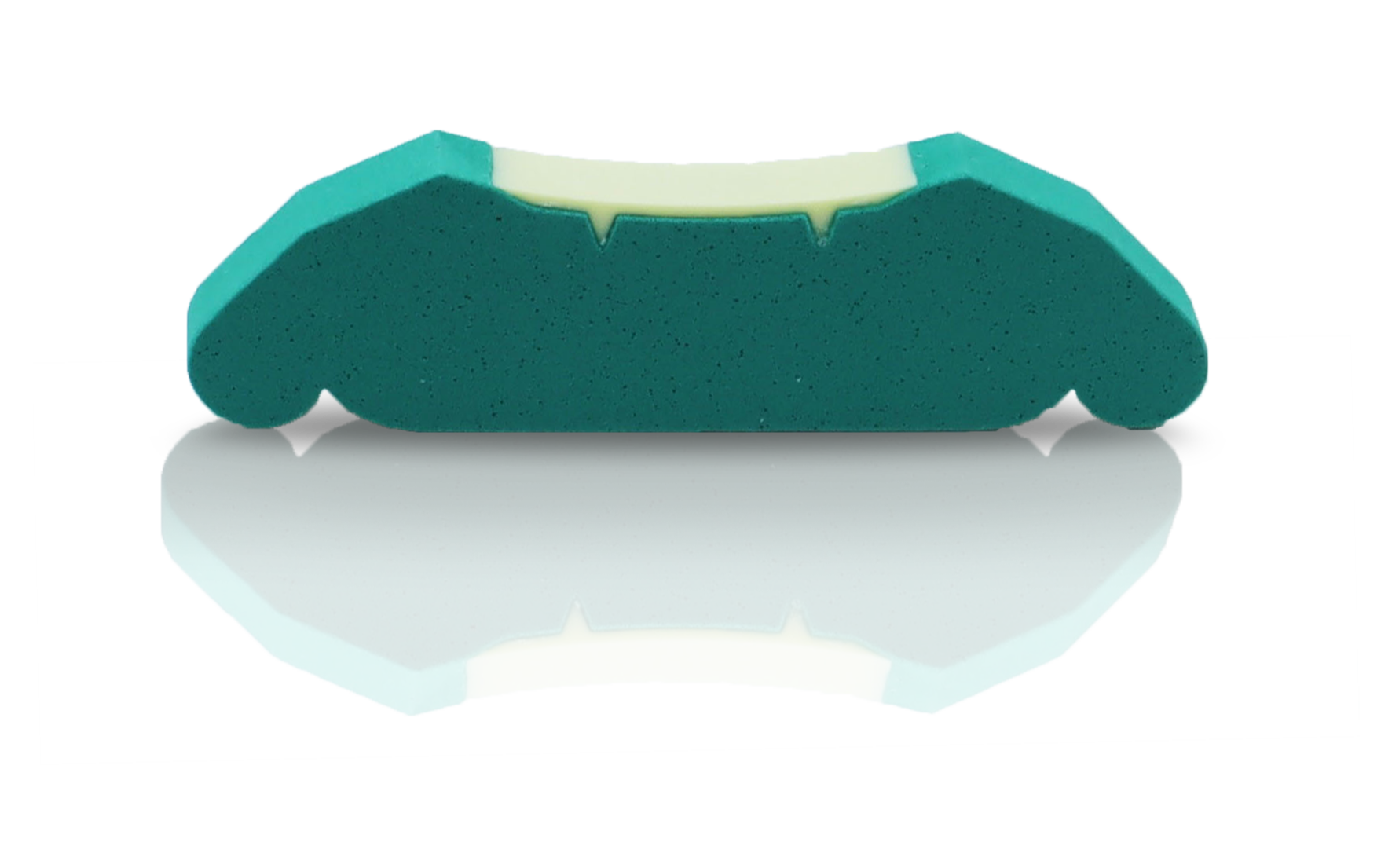

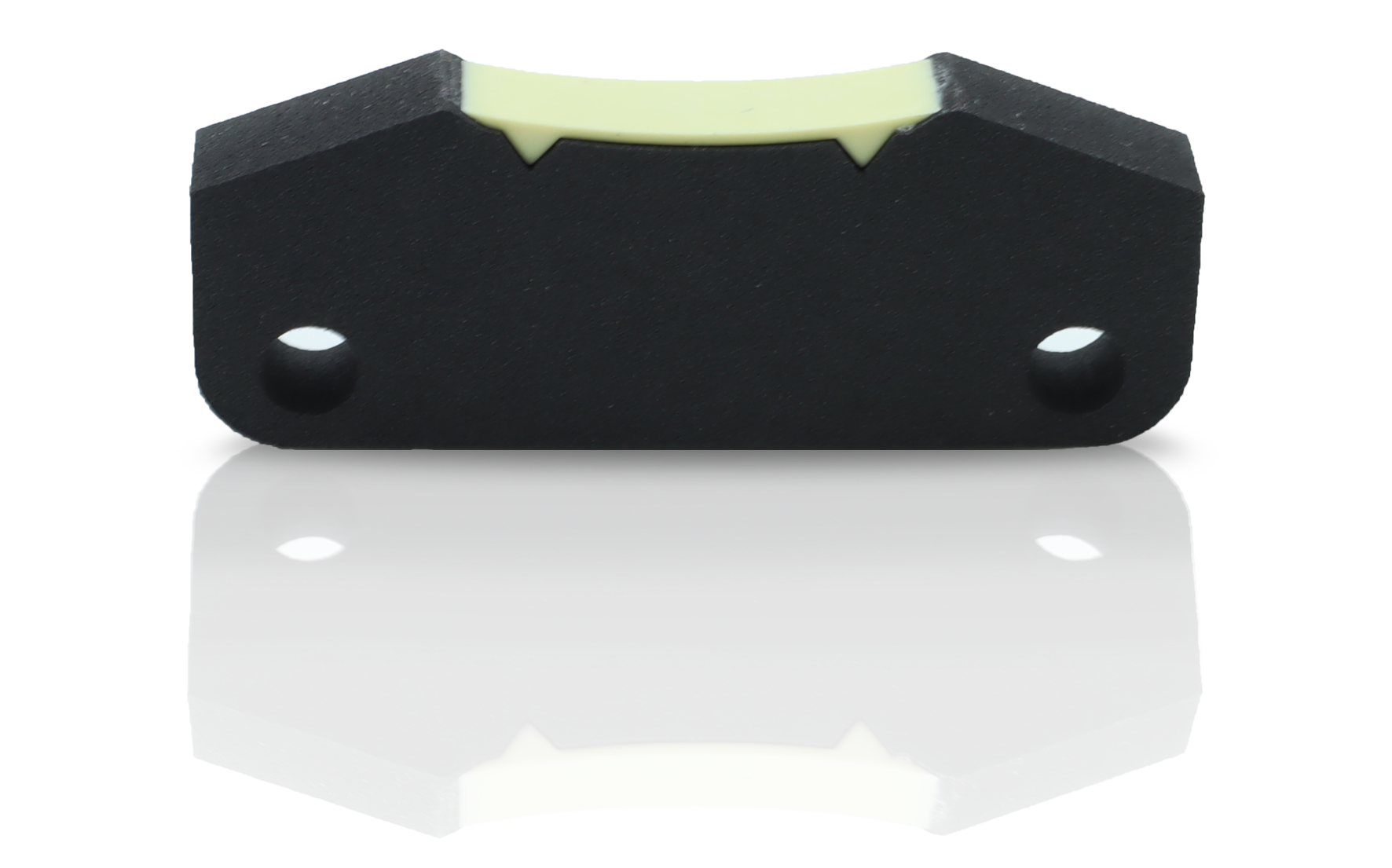

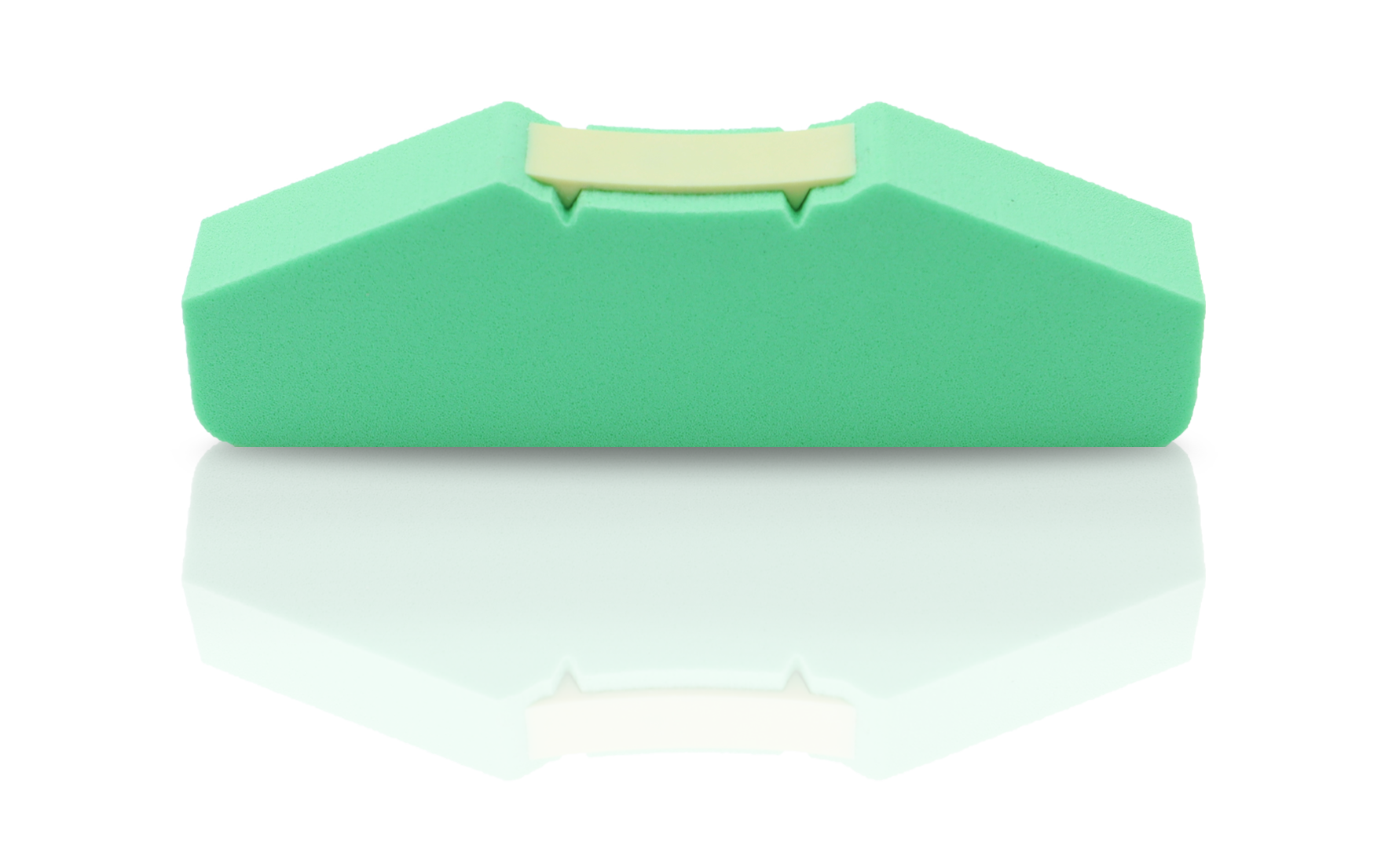

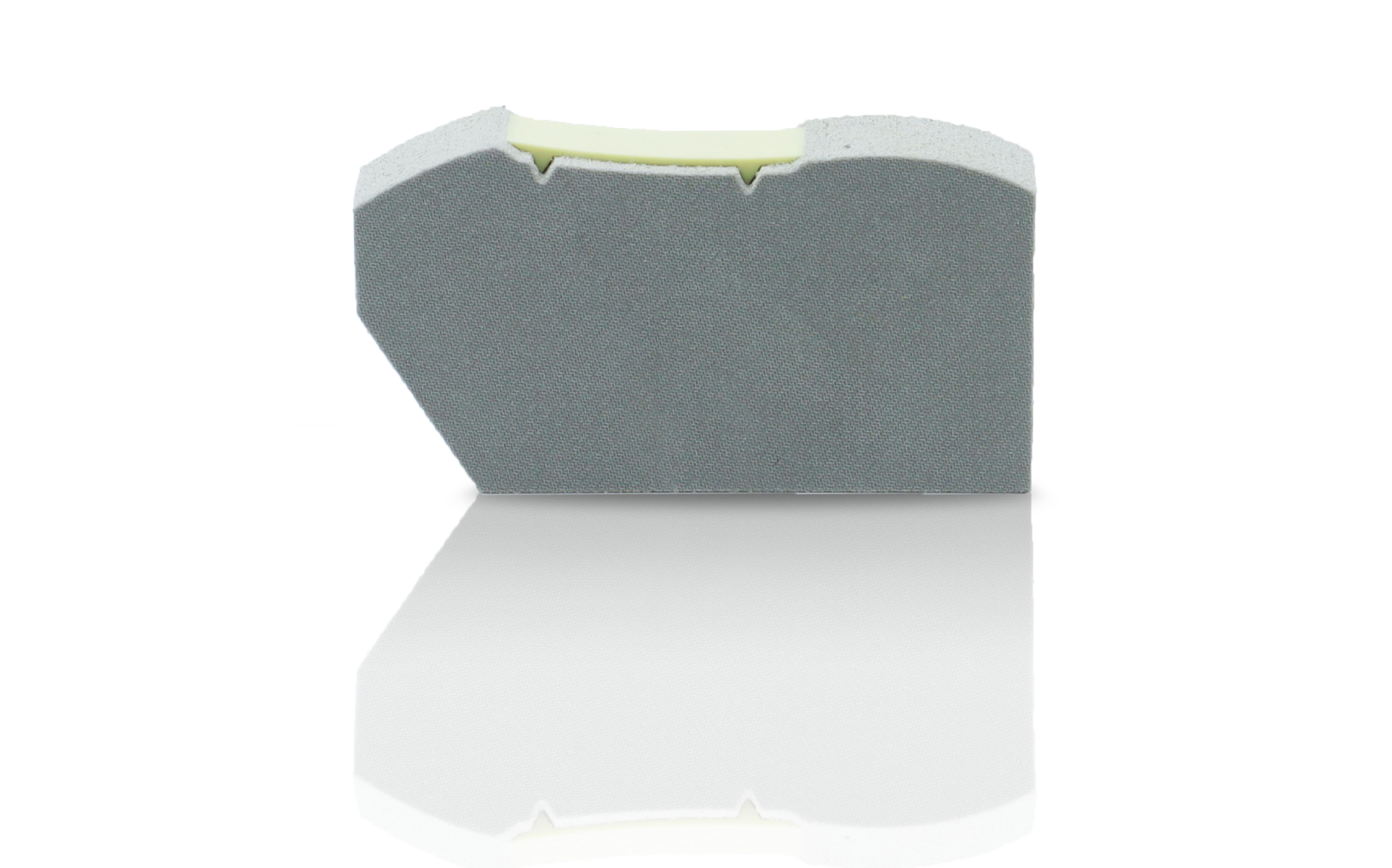

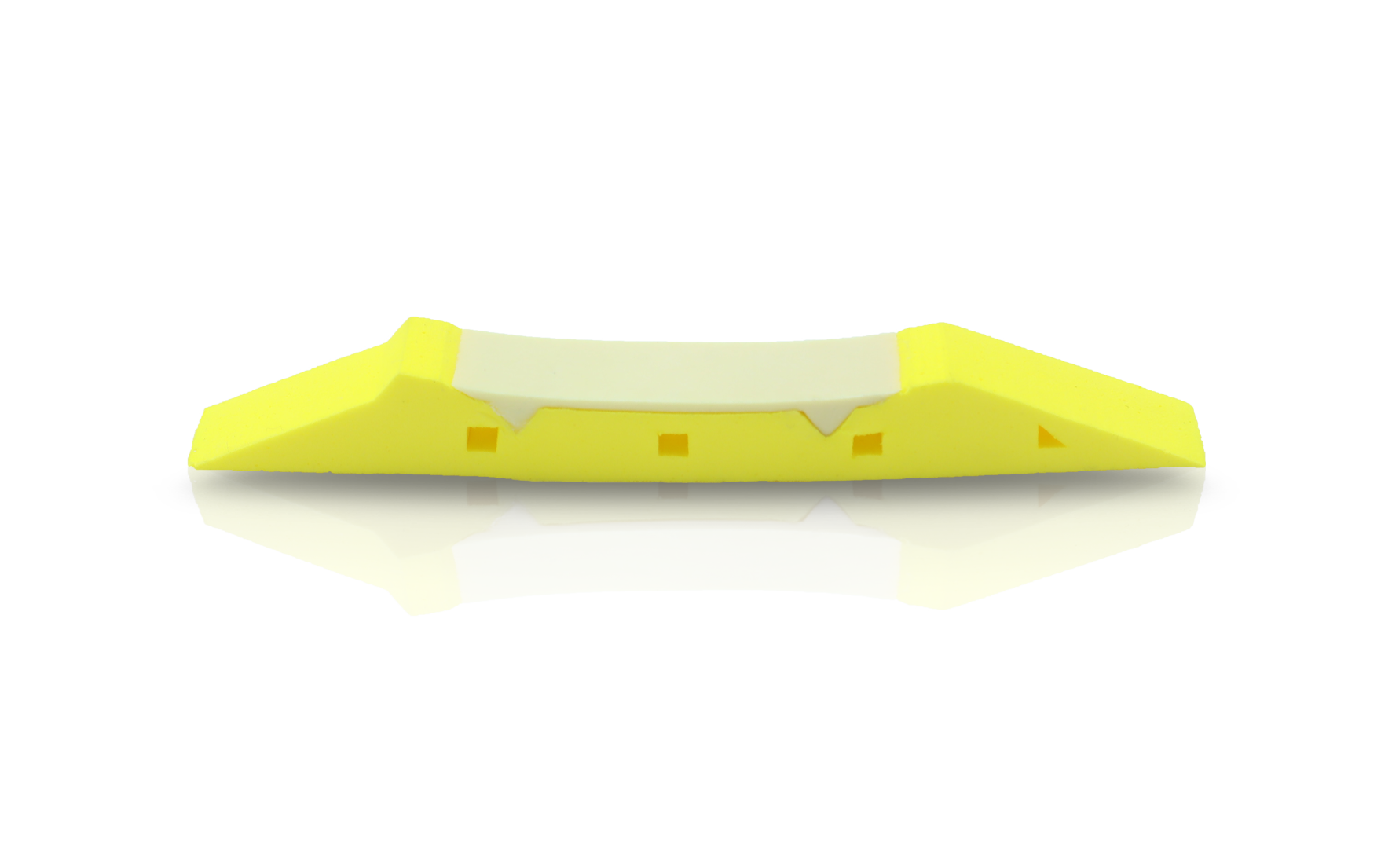

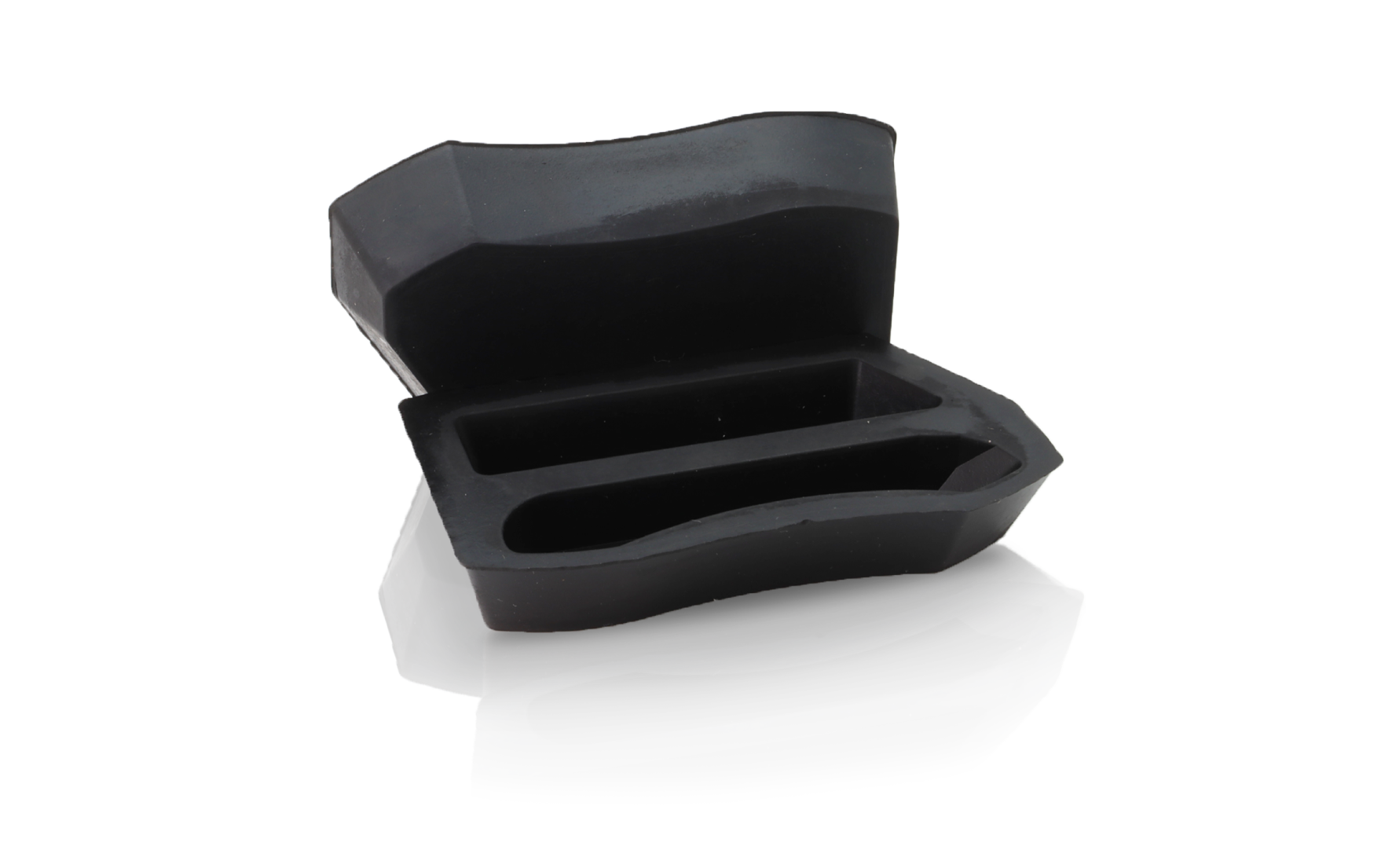

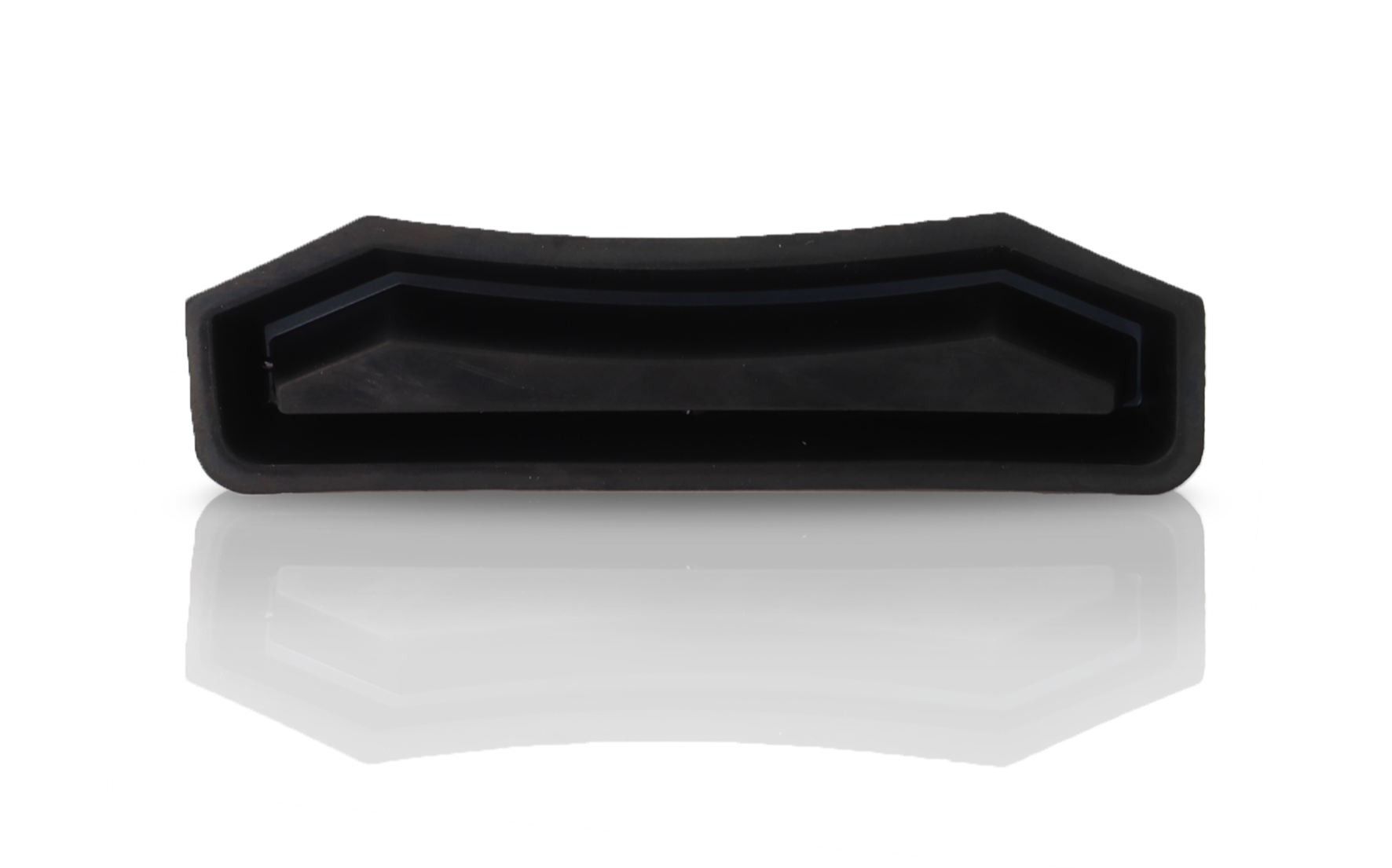

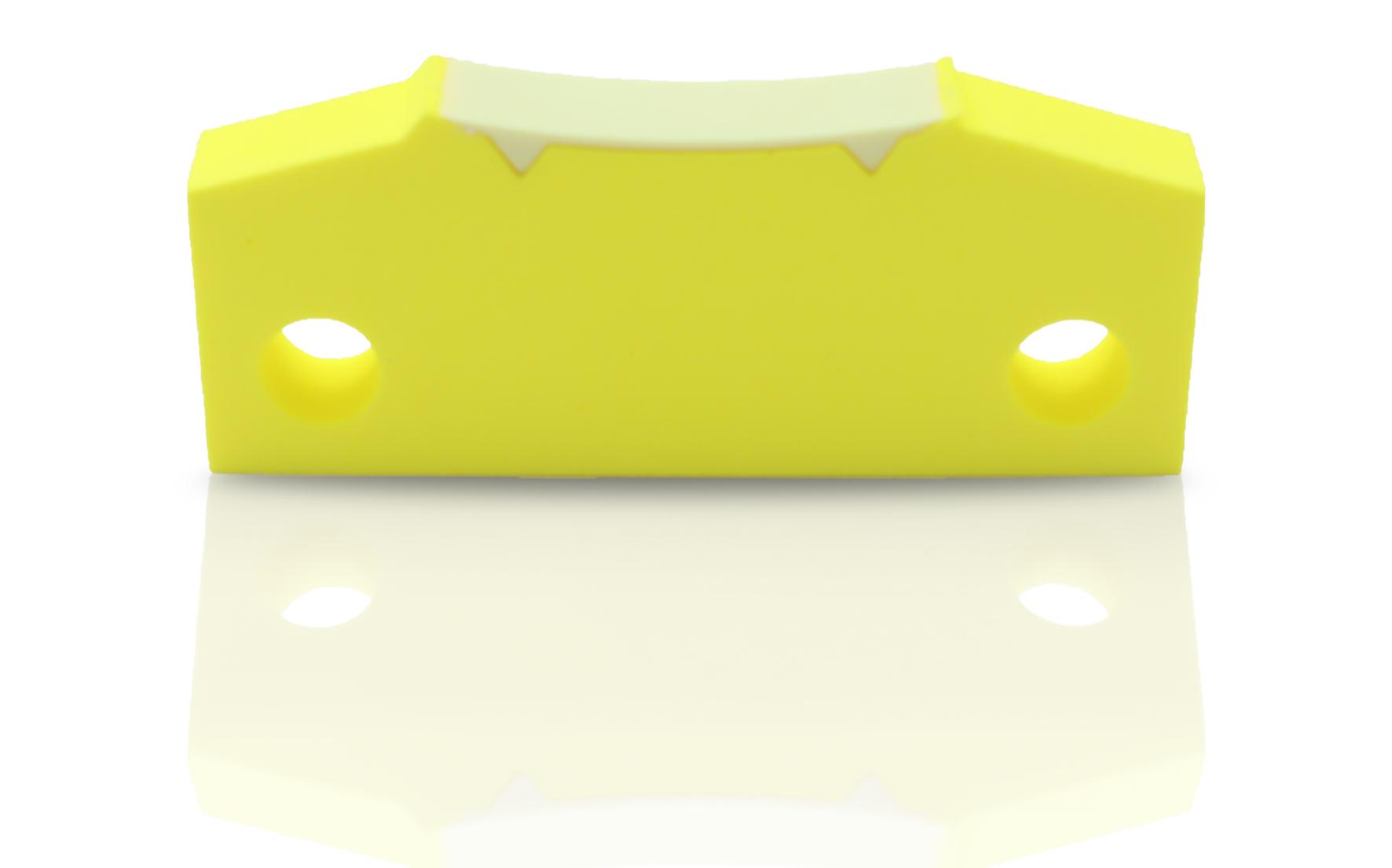

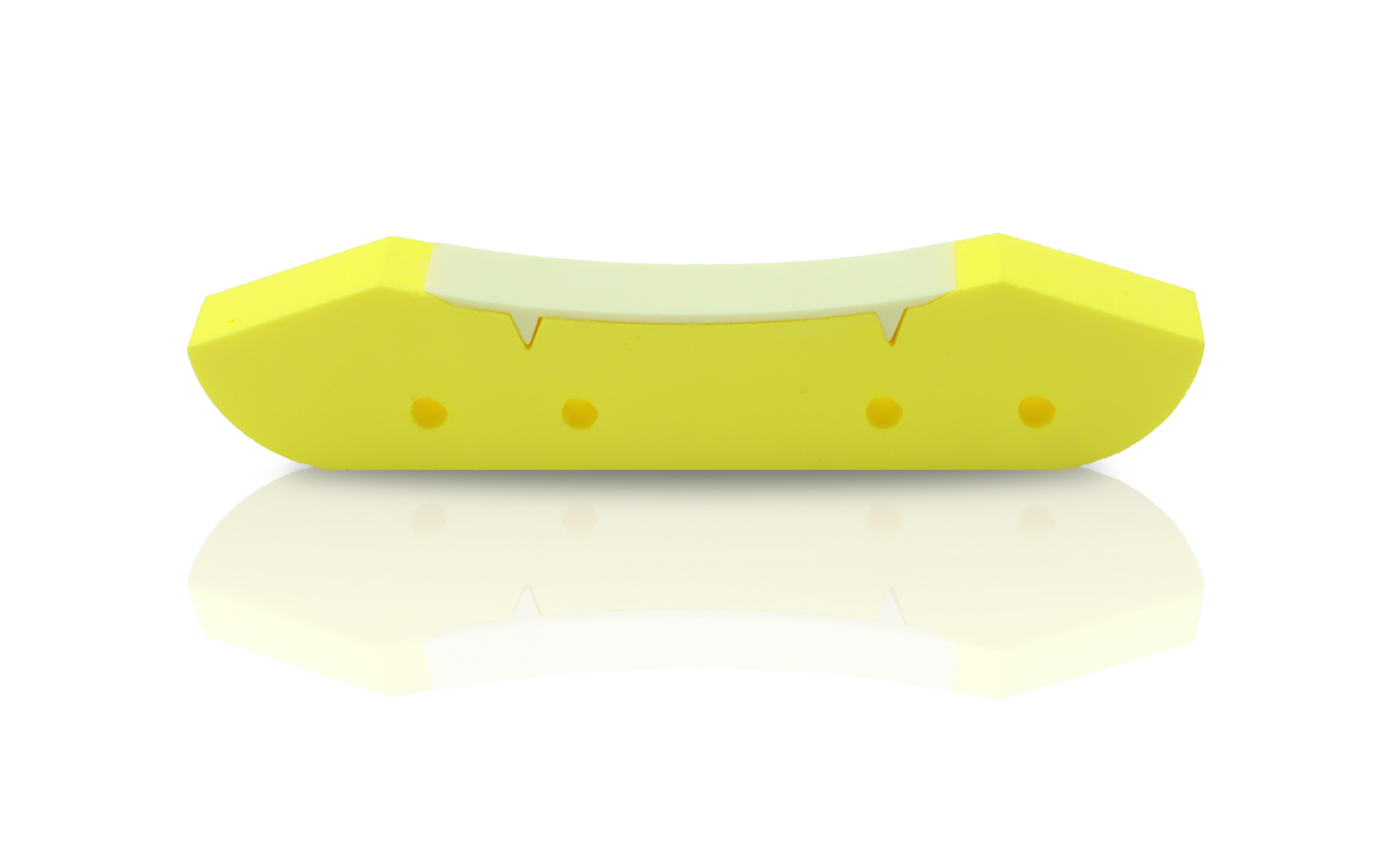

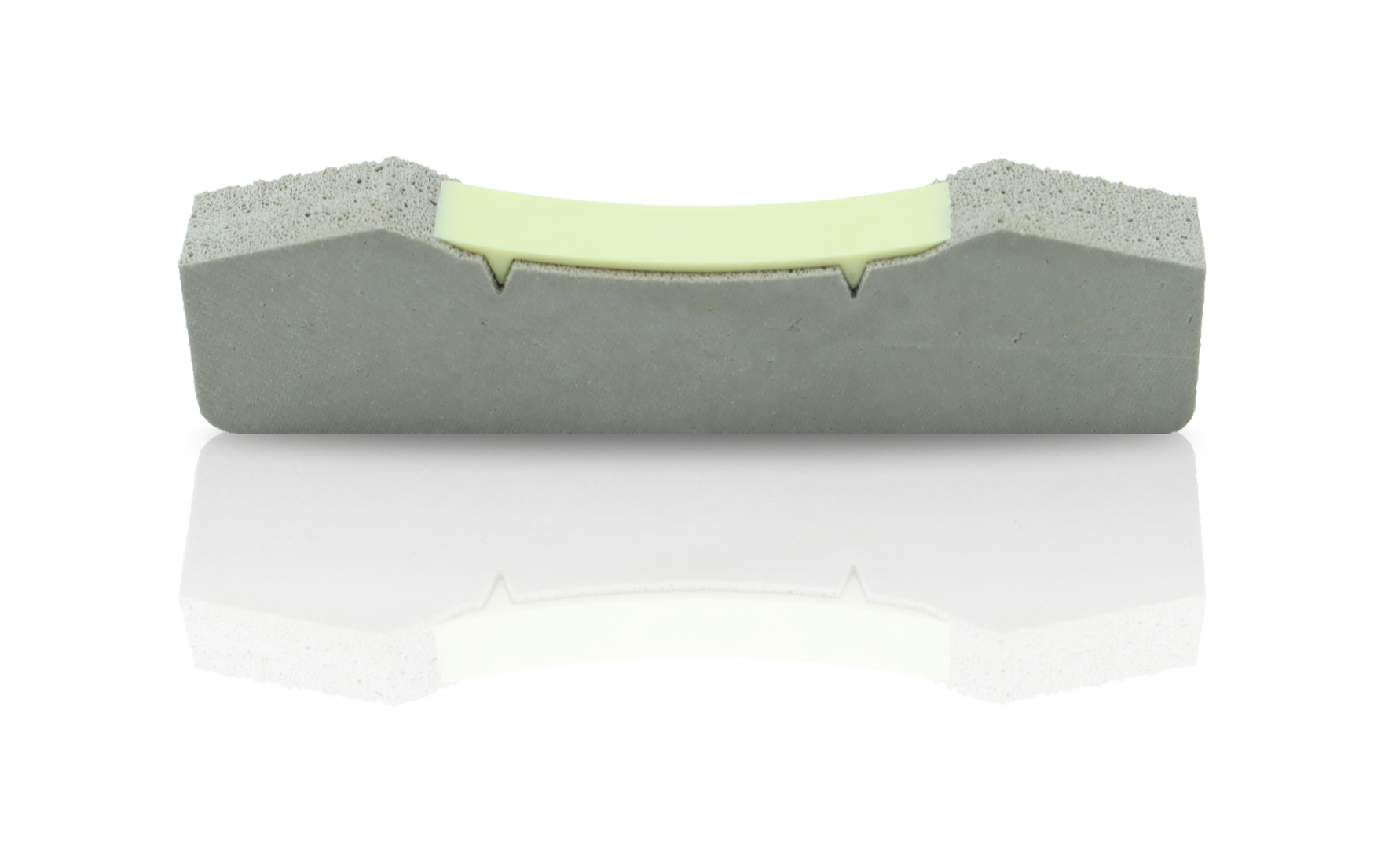

- ProSeals® are manufactured with superior materials in an exclusive process that provides a better seal and an extended life, up to 5 times longer than other industry standard seals

- Maximizes sealing properties for enclosed doctor blade systems and minimizes excessive pressure from doctor blade chambers

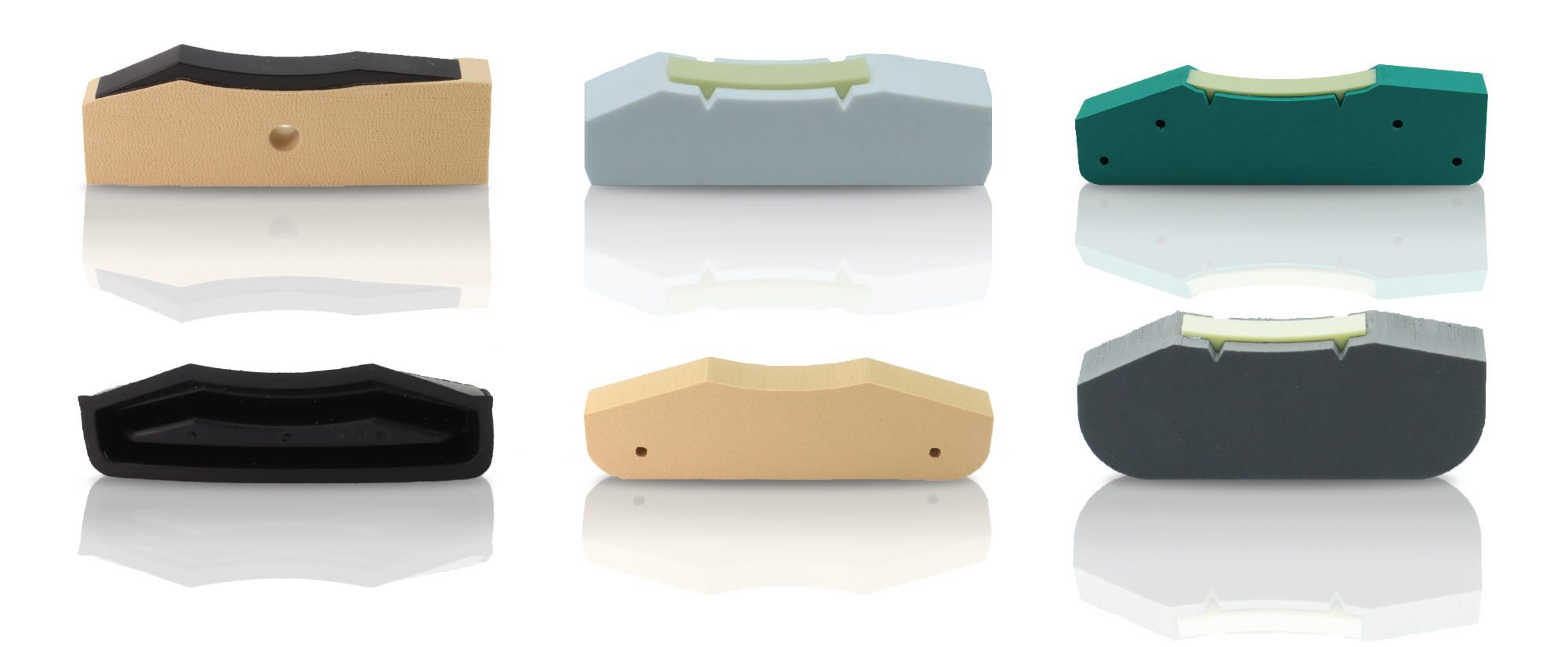

- A wide range of precision cut end seals are available for virtually any machine manufacturer and model

- Bundle up with SWED/CUT® Doctor Blades and start realizing the longer life benefits and elimination of waste

Proven Designs for Many Common Presses

We offer a wide range of precision cut end seals for flexographic printing presses, available for virtually any machine manufacturer and model including: Allstein, Aquaflex, Bobst F & K, Bonard, Comco, Comexi, Flexotechnica, FLSmidth, Harris & Bruno, Kidder, PCMC, Printco, Retroflex, Tresu, Uteco, W & D, and Windmoeller & Hoelscher (W&H).

SELECTION GUIDE

– Windmoeller & Hoelscher –

W&H Miraflex

W&H Miraflex

W&H Novaflex, Primaflex, Astraflex

W&H Vistaflex CL

W&H Soloflex

W&H Miraflex

W&H Miraflex

W&H Novaflex II

W&H Vistaflex

W&H Astraflex CL

W&H Miraflex

W&H Novaflex CL

W&H Vistaflex CL

W&H Novaflex XS

W&H Miraflex Retangle Rubber Gasket Overflow Assembly

– Bobst –

Bobst Expert 20Six, F&K 16s

Bobst 20Six

Bobst Vision

Bobst 20Six

Bobst Master CI 90Six, 30Six

Bobst 20Six

– Uteco –

Onyx

Onyx 876GL

Diamond, Onyx (Wide Web)

Crystal

Diamond

Quarz 613

– Comexi –

F1, F2 Plus

Sierra

– KBA Flexotechnica Cerutti –

Evo XD

Evo XD

– Allstein –

Allstein Press

Allstein Press

Allstein Press

Allstein Press

– Tresu –

D2

D3

D2

D4

D3

– Miscellaneous –

Gallus RCS330, ECS340, EM3405

Expert Press

Absolute S01021

Gallus RCS330, ECS340, EM3405

Expert Press

Absolute S04013

Soma Optima 1

Expert Press

Absolute S04009

– Corrugated –

Bobst Masterflex

Bobst Corrugated 200

Mitsubishi EVOL100

Bobst Masterflex

Gopfert Press

TCY Press

Bobst Martin

Gopfert Press

– Offset –

Manroland 505

Manroland 550