MFLEX PLUS®

The “GO – TO” Doctor Blade for High Speed HD FLEXO

MFLEX PLUS® for HD FLEXO is the latest development in SWEDEV’s range of printing doctor blades. This grade offers significantly higher wear resistance than other steel blades including high quality tool steels. The high hardness of PLUS®, due to its high occurence of very small and specially treated carbides, achieves longer blade life while reducing abrasion. As a result, this blade can achieve immediate seating to an anilox, maintain precise ink metering for longer periods at very high operating speeds and a reduction of anilox wear.

Extensive internal testing, supported by independently verified field tests with customers, confirms more than four times greater wear resistance compared with doctor blades made from standard types of carbon steel, specifically in demanding applications like white ink.

MFLEX PLUS® is particularly suited to deal with all types of inks including abrasive inks and coatings, such as white inks or other inks with high percentages of titanium dioxide and metallics.

MFLEX PLUS® OFFERS SIGNIFICANTLY HIGHER WEAR RESISTANCE THAN OTHER STEEL DOCTOR BLADES”

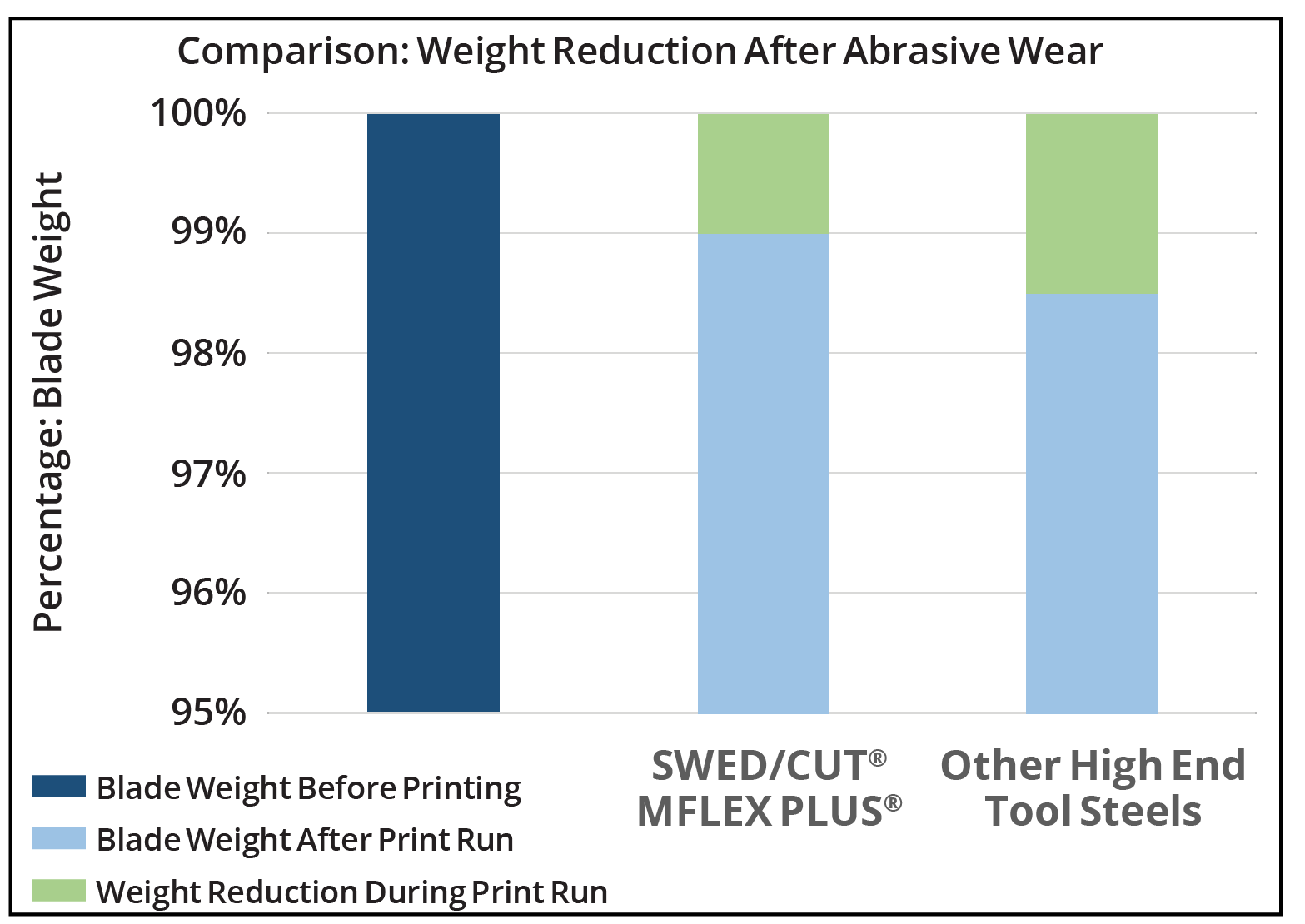

Comparison: Over time, MFLEX PLUS® shows 25% greater wear resistance compared with other high-end quality tool steels. (Aggregated results from several tests performed at SWEDEV’s R&D center. The weight loss of the material measured after wear is from a 175mm diameter, 40cm long anilox roller running at a pressure of 2 bar, 200 m/m for 16 hours in tap water.) The results are supported by field tests in actual production with customers. Results may vary according to specific variables.

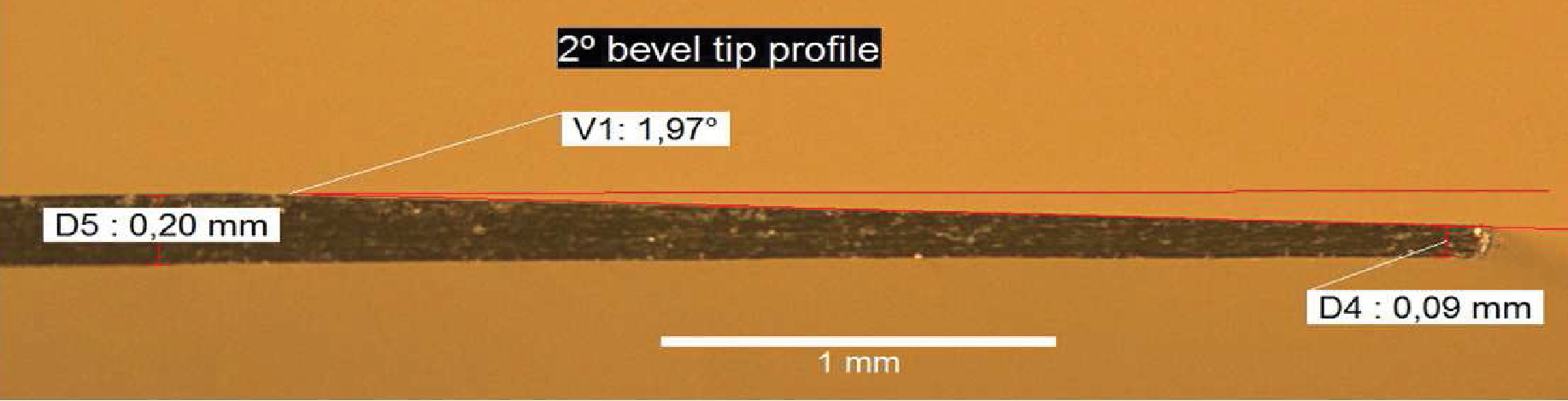

MFLEX PLUS® for HD FLEXO combines this new amazing steel with a more rigid tip that achieves a clean wipe from the start and for millions of feet. This enhanced tip gives the performance value of a lamella without the flex and maintains a more narrow contact area.

While doctor blades were often the overlooked element in the Flexo process, they aren’t anymore. Blades have more to do with process success than ever before. Armed with the right blade, a flexographic printer can totally eliminate process waste like UV spitting, streaks, anilox damage, back-doctoring, and do so running at very high speeds for longer periods.

ULTIMATE PERFORMANCE FOR LOW IMPACT & LONGER BLADE LIFE

M-FLEX® Plus is our most wear resistant, non-coated, ultra-refined carbon steel that maintains precise metering of water and solvent inks or coarse coatings. It is reported to maintain precise metering for ink and coating applications many times longer than other non-coated blades and some coated blades.

FEATURES & BENEFITS

M-FLEX® Plus is ideal for use in HIGH SPEED HD FLEXO environments including Expanded Color Gamut providing precise metering for all print types including high screen print. It has been proven to help prevent back doctoring and significantly lowers anilox wear and scoring. It is safe for use on high line count anilox at very high speeds.

IDEAL APPLICATIONS

- Process: HD FLEXO, GRAVURE, COATING

- Industry Segments: Wide Web, Narrow Web

- Recubrimientos & Laminados

- Tintas UV y varnices UV

FEATURES

- Tolerancias mínimas

- Enhanced Micro Carbides

- Carburos más pequeños con distribución más densa y pareja

- Biselado largo y afilado

BENEFITS

- Filo más fino y estable

- Desgaste lento y parejo

- No necesita tiempo para ajustarse

- Fácilmente se usa a altas velocidades

- Previene impresión sucia y ganancia de puntos en tirajes largos

- Menos desgaste al anilox, cilindro y rodillos de recubrimiento

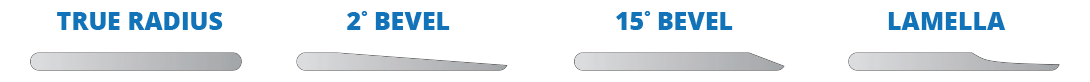

AVAILABLE BLADE EDGE PROFILES

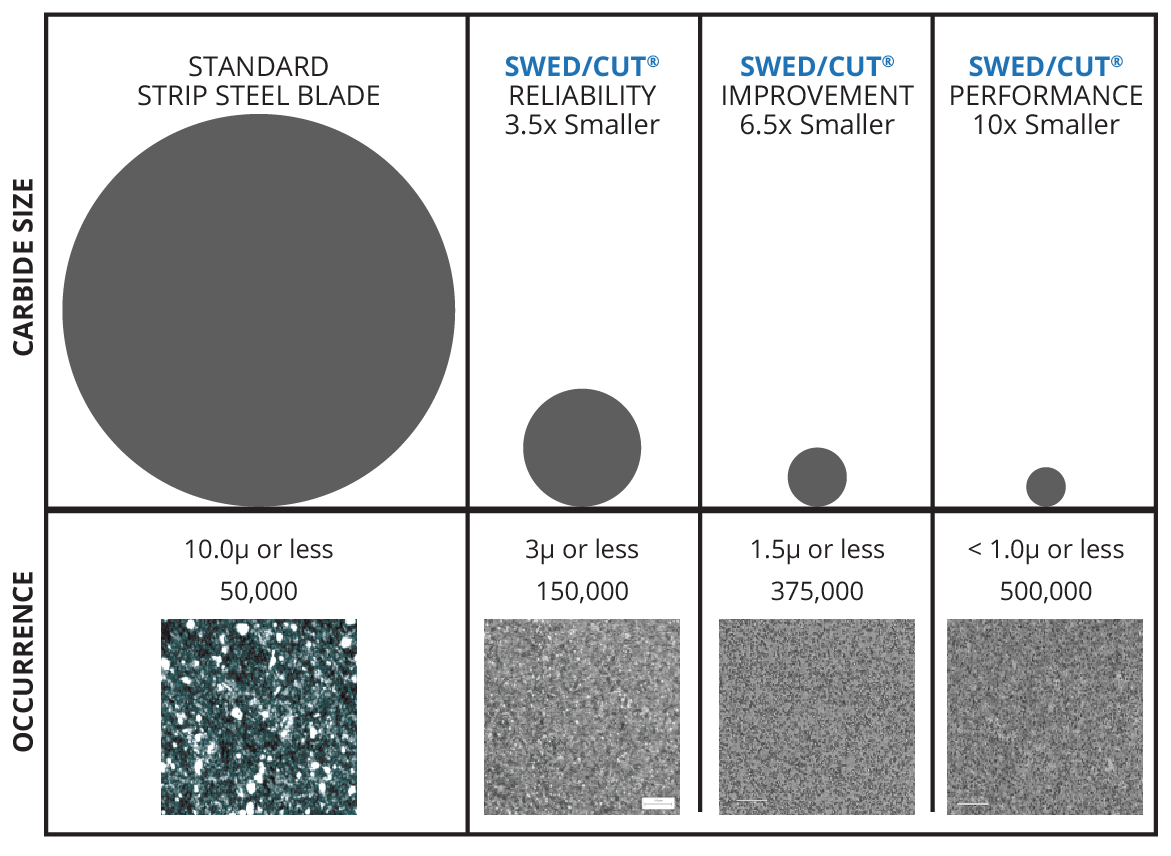

MICROSTRUCTURE MATTERS

Compared to standard strip steel, the M-FLEX® Plus doctor blade’s microstructure is defined by it’s small and evenly distributed carbide particulate which assures slow and even edge wear, low friction, and smooth ink film formation. For you that means a higher quality doctor blade that reduces the likelihood of common print defects, reduces wear to your anilox rolls, and allows you to run your blades longer.

THE QUANTITY & SIZE OF CARBIDES ARE KEY TO A GREAT DOCTOR BLADE

REDUCE YOUR ANILOX & BLADE EDGE WEAR

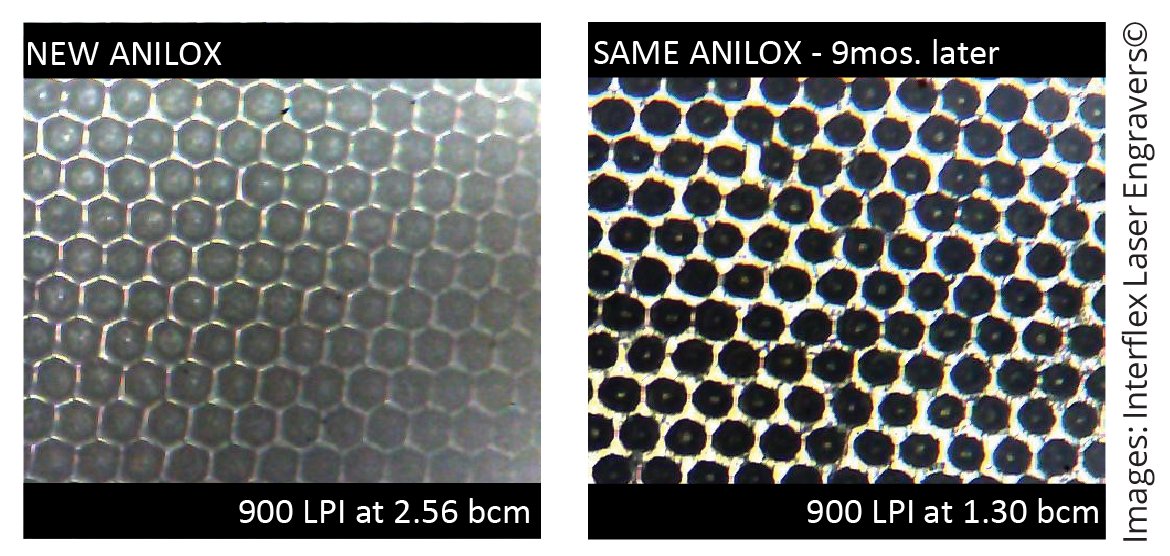

ANILOX WEAR

Supported by field tests, MFLEX PLUS® shows a 25% greater wear resistance over time compared to other high-end tool steels. In just 9 months, the below anilox has lost ±50% of its volume to wear caused by running standard strip steel blades.

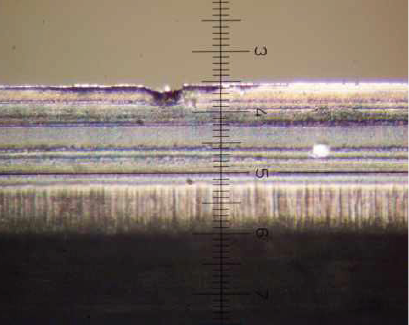

BLADE EDGE WEAR

An example of a doctor blade’s edge wear after extreme pressure is applied to gain clean wipe. The contact area is widened by 3x.

FLXON / SWEDEV offers a wide range of high-quality steel, coated, and plastic doctor blades. We can help you find the best one for your application. If you need help with assessments or training for the best doctor blade solution, contact one of our experts for a consultative evaluation. Our team will be able to help you with solutions.