G2 High Release Coating

Desprende practicamente cualquier producto de potencia industrial

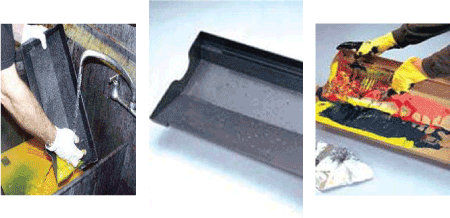

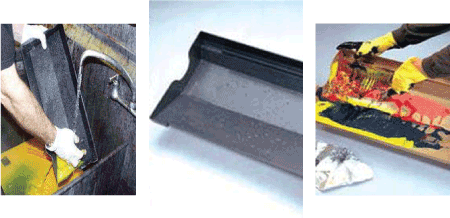

High Release Coating eliminates color contamination and reduces downtime for cleanings. Applicable to any existing equipment or specified to new equipment manufactured before delivery.

FLXON has partnered with KECO Engineered Coatings, a leading industrial coater in North America. Founded in 1980, KECO Engineered Coatings, Inc. is a nationally recognized industry leader specializing in developing and applying lab tested and technically superior coatings. KECO’s coatings increase the quality and performance of a product, while maintaining its integrity, and decrease the overall labor costs and production expense.

KECO Coatings is one of just 23 licensed Chemours Teflon® industrial applicators (LIAs) in the U.S. KECO’s signature coating portfolio includes antimicrobial, automated powder, ceramics, dry film lube, epoxy, liquid, plasma, thermal barrier thermoplastic, and plasma. KECO’s service industries include aircraft, automotive, CPI, food processing, HVAC, lighting, OEM, packaging, pharmaceutical, semiconductor, transportation, and more. KECO dedicates a significant amount of resources to guarantee the quality and reliability of its products. It is an integral part of KECO’s mission and substantiated through its ISO 9001:2015 certification.

FLXON facilitates customized applied coatings for use by the Flexographic and Rotogravure printing, coating and laminations industry. Market segments include label and flexible packaging, folding carton, kraft and multi-wall bags, envelope, liquid packaging.

Prevents Dried Inks & Coatings from Sticking

- Makes clean up easy – using plastic squeegee, no metal scrappers – wet & wipe

- Reduce downtime – 90% of customers report less downtime

- Prevents color contamination

- Durable, genuine Teflon® family of non-stick coatings that can be applied to: pans, covers, ink sumps, pails, lids, idler rolls, turn bars, heat seal, tension rollers, doctor blade holders, chambers, and any part that fluids dry on and buildup

- Non-stick: all types of inks, varnishes, adhesives, and coatings

- Coatings available: K100 Conductive and K800 Non Conductive (Safety Feature – K800 eliminates static charge build-up)

Aplicaciones Ideales

- Rollers/Bars: Idle, Guide, Impression Rollers

- Inks/Coatings: For Inks – Pans, Pumps, Pails / For Adhesives: Sumps, Pails

- Miscellaneous: Doctor Blade Holders, Doctor Blade Chambers, Turn Bars, Heat Seal Bars