SWED/CUT M-FLEX I

Reliable long life performance and excellent wear resistance.

SWED/CUT M-FLEX I® | Reliability Class Doctor Blades

M-FLEX® I is great for basic shorter runs with frequent blade change environments in print and coating applications where consistent precise metering is required. It is formulated of high-density, non-coated carbon steel that exhibits excellent wear resistance and uniform edge wear. M-FLEX® I is an ideal doctor blade for metering solids, line work, screens, and basic process using solvent and water based inks. It is particularly suited for wide web flexibles, multi-wall bags, kraft bags, and more.

Ideal Applications

- Process: Flexo, Gravure, and Coating

- Industry Segments: Wide Web

Features

- Tight Tolerances

- Small Even Carbide Distribution

Benefits

- Slow Even Wear

- No Break-in Time

- Even Metering Side-to-Side

- Less Wearing to Anilox, Cylinder & Coating Rolls

Characteristics Compared to Standard Strip Steel

- Carbon Single-Sourced Steel

- Carbide Sizes: 3 times smaller

- Carbides/mm∧2: 3 times more

- Friction Level: 10 times lower

- Corrosion Resistance: XX

- Life: X

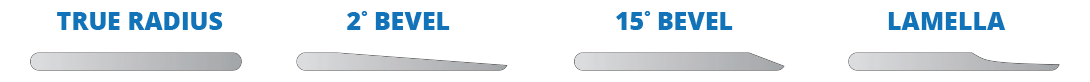

Available Blade Edge Profiles

The M-FLEX I® doctor blade is available in the following blade edge profiles.

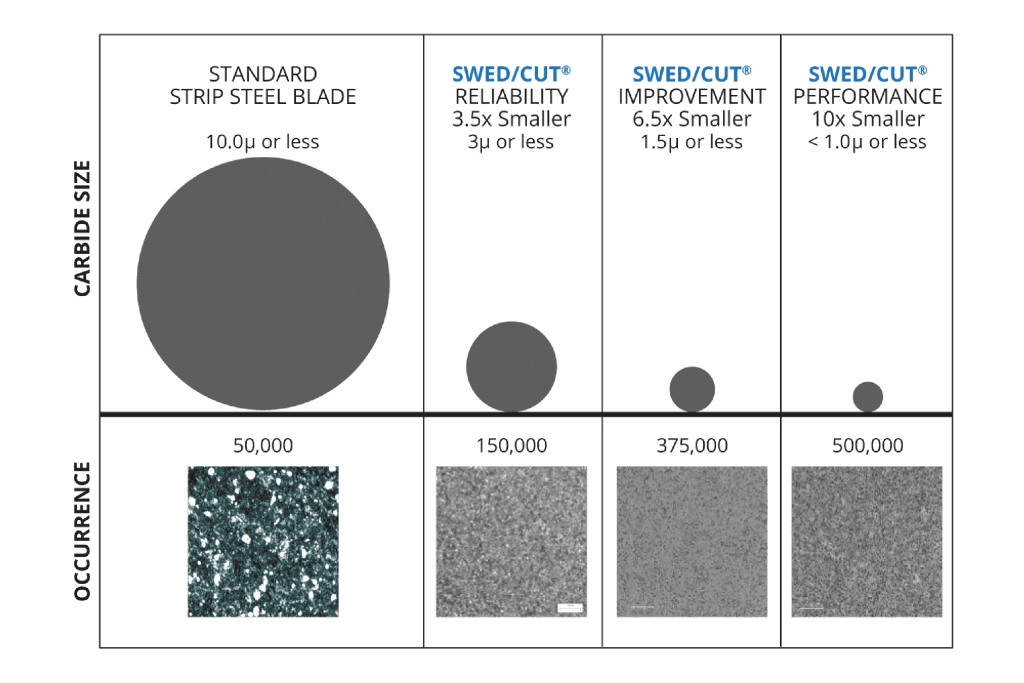

Microstructure Matters

The M-FLEX I® combines corrosion resistant micro-refined chemistry with physical dimension and extended bevel to combat UV spitting and other similar print defects. It is a top performer for long running printing and coating applications requiring consistent and precise metering.

Compared to standard strip steel, the M-FLEX I® doctor blade’s microstructure is defined by it’s small and evenly distributed carbide particulate which assures slow and even edge wear, low friction, and smooth ink film formation.

For you that means a higher quality doctor blade that reduces the likelihood of common print defects, reduces wear to your anilox rolls, and allows you to run your blades longer.