Doctor Blades

Our range of SWED/CUT® highly refined micro structured carbon, stainless, and coated steel doctor blades are developed to perform better and to meet the specific needs of your printing and coating applications.

Highly Specialized Doctor Blades for Longer Life

Processes

Flexo, Roto, Offset Coaters, Hot Melt, Cold Seal, Laminations

Applications

Narrow Web, Wide Web, Sheet Fed Carton, Corrugated

Industry Segments

Food Packaging, Shrink Sleeves, Pouches, Tag & Label, Pharmaceutical & Medical Packaging, Liquid Packaging, Envelopes, Gift Wrap, Wall Coverings, Specialty Coatings

Ink Types

Water, Solvent, UV, EB, LED

Doctor Blades – Flexo, Roto, Coatings, Laminations

FLXON is the exclusive distributor of SWED/CUT® performance doctor blades in North America which include a variety of doctor blade materials ranging from economical reliability to high performance options all designed to boost your pressroom’s performance. SWED/CUT® is manufactured of high quality carbon, stainless, and coated steels known for their micro-refined structures and slow, even edge wear that are a higher strength, reduce friction, and exhibit less flex to achieve a cleaner wipe.

Download SWED/CUT® Selection Guide

The Safe & Reliable Choice in Doctor Blades

Higher Quality

A range of high quality carbon, stainless and coated steels, known for their micro refined structures and slow, even edge wear.

Precise Dimensions

All physical tolerances for width, thickness, length, and edge treatments are achieved under strict ISO CERTIFIED Quality Assurance Program.

Improved Metering

Reduced friction, higher strength, and less flex help to achieve a cleaner wipe for longer periods avoiding print defects like dot gain and spitting.

Customer Service:

(800) 756-6474

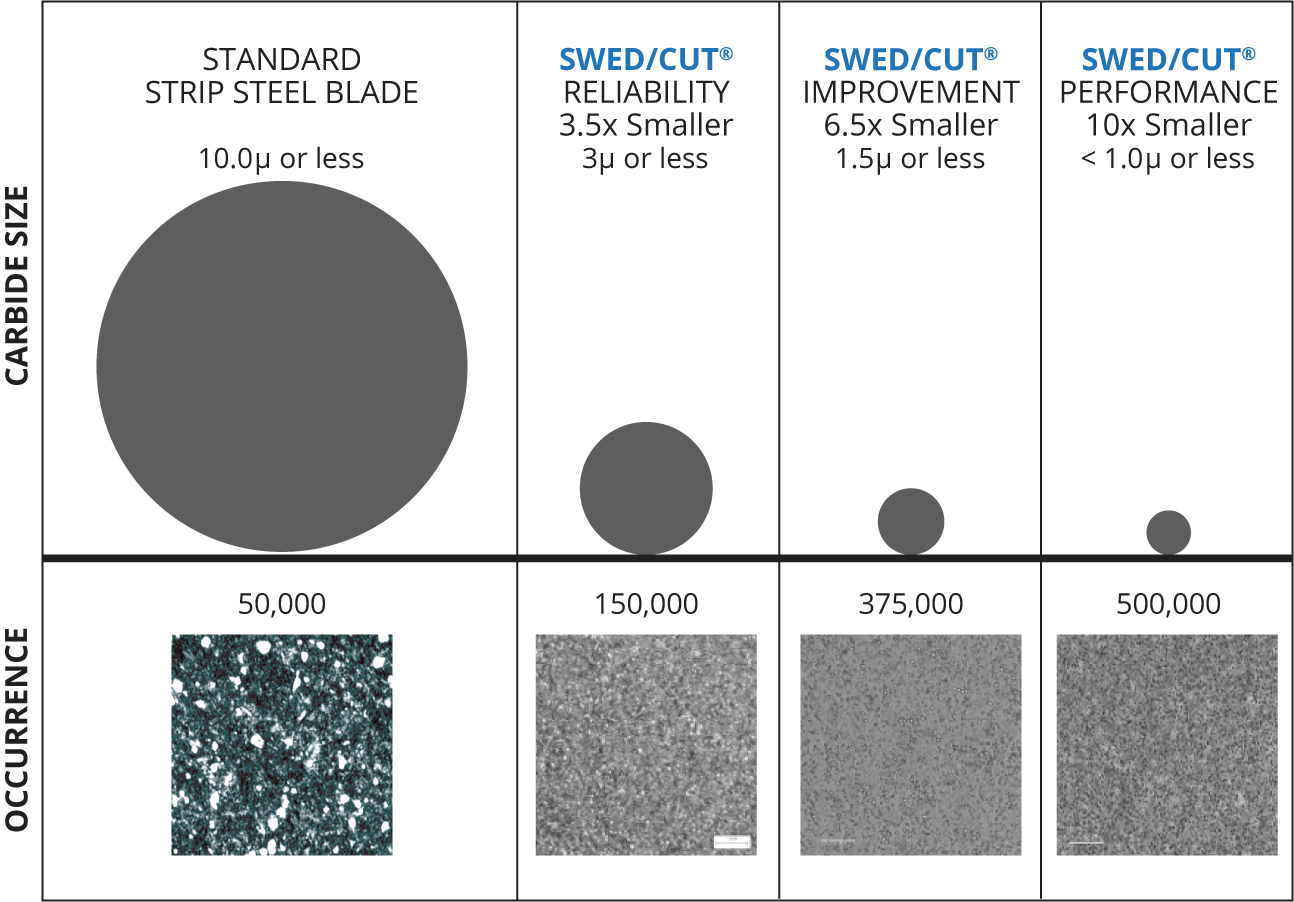

Microstructure Matters

Compared to standard strip steel, the microstructure of SWED/CUT® is defined by small and evenly distributed carbide particulate which assures slow and even edge wear, low friction, and smooth ink film formation. For you that means a higher quality doctor blade that reduces the likelihood of common print defects, reduces wear to your anilox rolls, and allows you to run your blades longer.

The Quantity & Size of Carbides Are Key To A Great Doctor Blade

Compatible OEMs

SWED/CUT® continually outperforms other doctor blade brands on the industry’s top performing flexographic and rotogravure presses.

Bobst, Mark Andy, Windmoeller & Hoelscher (W&H), Nilpeter, Uteco, MPS, Fischer & Krecke (F&K), Harris & Bruno, Tresu, Comexi, Koenig & Bauer (KBA), Allstein, Aquaflex PCMC, Omet, Heidelberg, Primoflex, Retroflex, Soma, Absolute, Gallus, Expert, Pannier, Sobu, KYMC, Bonard, Comco, Printco, FLSmidth, Schiavi, W&D, Kidder, Rotomec, Cerutti, Hsing Wei and many others.

Dimensions

Our high-performance doctor blades are manufactured in a full range of widths, lengths, and thicknesses specially designed to meet the needs of your pressroom.