Boost Your Pressroom Performance

We continually strive to help move the printing, packaging, and coating industry forward through innovation, increased productivity, advanced technology, and a vision to meet the demands of the ever-changing pressroom. Receive a NO-COST, NO-RISK evaluation of your pressroom.

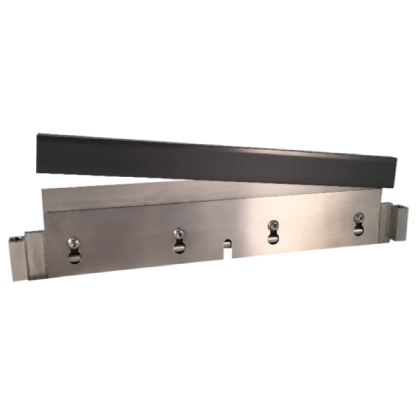

Doctor Blades

FLXON is the exclusive distributor of SWED/CUT® performance doctor blades in North America which include a variety of doctor blade materials ranging from economical reliability to high performance options all designed to boost your pressroom’s performance.

Flexo Solutions

Innovative products and services tailored to meet specific flexographic print needs for Narrow Web and Wide Web packaging printers including doctor blades, ink pumps, ink filters, doctor blade holders and chamber systems, ink management solutions, and pressroom safety.

Roto Solutions

We also offer rotogravure products and services including doctor blades, ink pumps, ink filters, doctor blade holders and chamber systems, ink management solutions, and pressroom safety – designed to eliminate print defects, reduce downtime, and increase speeds.

High-performance pressroom products to improve your

Productivity, Safety, and Performance.

Ready To Learn More?

Request A Quote. Schedule A Pressroom Assessment. Try A New Blade.

SWED/CUT® H9:

New Technologically Enhanced Doctor Blade

H9® introduces a totally new and innovative technologically enhanced coating for extreme wear resistance without extreme hardness. It is combined with our high-density carbon steel doctor blade material for superior performance in the most demanding print and coating applications. H9® achieves great results for applications in flexo print and coating, lab tech applications, and other challenging environments.

Customer Service:

(800) 756-6474

Pressroom Process Technology Consulting

Our PTC service program offers pressroom audits that identify cost and waste reduction opportunities as well as a clear, easy to follow implementation program. PTC also offers operator and management best practices training as well as compliance audits. Benefits are guaranteed and are reported to far exceed cost and expectations.

Client Testimonials

“Any defect, any mid-run press stop, can entirely eliminate margin from a job. As QA manager, it is up to me to prevent waste before it happens. That’s why I rely on FLXON and SWED/CUT doctor blades to gain our competitive advantage.”

“As a manager, I am tasked with adding to our bottom line from within our manufacturing process, I knew I needed help from the outside. We connected with FLXON and their PTC services, their depth of experience based knowledge made all the difference in the world. Detailed audits, on-press operator training, and easy to accomplish process improvement recommendations helped us exceed our targets. Process Improvement isn’t a destination – it is an ongoing process that requires expert support from partners like FLXON.”

“We placed your recommended SWED/CUT doctor blades on our white deck and days later we still have ZERO leakage! At first I was skeptical, but now the first to admit that you truly do have the ultimate doctor blade for our high speed flexo press. Still in amazement at the results. We are now averaging 4 days run time with almost no leakage on both colors or whites!”

Eliminate Costly Defects, Waste & Downtime

Find out what others have already discovered!

Over 25 Years of Service

For over 25 years we have helped flexographic and rotogravure printers eliminate print defects, drive out waste, reduce press downtime, increase press speeds, and ultimately lower the cost-of-goods sold to achieve a higher gross margin.

We know that in today’s pressrooms, our customers require a prompt and right solution for their specific needs. At FLXON, we keep customer satisfaction as our top priority. Part of that is ensuring we are committed to providing the highest quality and best selection of doctor blades, on-press equipment, pressroom accessories, and technical assistance.

Through the years we have earned a reputation for continually improving and striving for improved doctor blade and pressroom equipment technology to meet the ever increasing demands of flexographic and rotogravure pressrooms.

Along with SWEDEV AB, manufacturer of SWED/CUT® Performance Doctor Blades, we are committed to employing the latest technologies and advancements in materials to provide innovative, cutting-edge products to printers through doctor blade technology. precision ink metering, ink flow management, and operator training.

Years Established

US Coast to Coast Trips in Blade Material

Innovation & Advanced Technology

There are many details within the structure of the materials used to make high performance doctor blades. We are committed to research, analysis, and high-technology to assist in developing more advanced doctor blades.

Our commitment is to assist in the development of better doctor blades that meter more precisely, last longer with less negative impact, and eliminate waste and downtime from the production process.

Events

CBIG 5P Showcase

February 25-26, 2025

Appleton, WI

LabelExpo Mexico

April 1-3, 2025

Guadalajara, MX

FTA Forum & InfoFlex

May 4-7, 2025

Pittsburgh, PA

News

Perfect Doctor Blade for Every Pressroom: 5 Reasons to choose SWED/CUT Doctor Blades

The Perfect Doctor Blade for Every Pressroom 5 Reasons to Choose SWED/CUT® Doctor Blades SWED/CUT® provides a product range of blades for flexo, gravure, and coating applications, designed for precise metering and high-quality print with minimal pressure to reduce ink...

Steve Boettcher: 20 years and going strong at FLXON!

Steve Boettcher: 20 years and going strong at FLXON! Join us in celebrating Steve's 20th Anniversary as our Technical Services Manager! 40 years ago, Steve Boettcher began his career in printing along Highway 41 in his native Wisconsin. For the next two decades, Steve...

Articles

Benefits of Converting a Rotogravure Coating Process to an Enclosed Doctor Blade Chamber

Benefits of Converting a Rotogravure Coating Process to an Enclosed Doctor Blade System: Featured in the June 2023 Edition of Gravure Exchange Author: Jason Wilhelm, Product Line Manager, FLXON Many of today's printers and converters have relied heavily on the...

Doctor Blades Are a Key Component for Flexographic Printers to Make Money

DOCTOR BLADES: A Key Process Variable | FLEXO Magazine | June 2022Fundamentally, 2022’s challenge for flexographic pressrooms is the same as it’s always been. That challenge is to generate a bottom line, a net profit or net income at a level needed to sustain...